AIX-ray Inspection System

AIOptical Sorting System

products

-

AI X-Ray Inspection System for Bulk Products

learn moreConventional and unconventional contaminant detection (high and low density contaminants, organic contaminants, wormholes, defects, etc) & vision and shape sorting, high-precision air jet rejector with minimal waste

-

.png)

AI Medium Speed Belt Optical Sorter

learn moreDesigned for dry, wet, and frozen materials, and widely applied to products prone to damage or containing moisture, oil, or high dust levels. The AI-powered sorter features multi-view imaging and up to IP66K protection.

-

AI Standard Food X-Ray Inspection System

learn moreFor foreign contaminant detection, offering complete tunnel size options, versatile machine configurations, and AI-powered large models, suitable for both packaged and unpackaged products across all food industries.

-

AI Multi Beam Belt Optical Sorter

learn moreWidely applied to vegetables, fruits, meat products, seafood, nuts, and more. Equipped with multi-view imaging for nearly 360° coverage, enabling efficient micro-defect detection even in hard-to-reach areas.

-

.png)

AI X-Ray Inspection System for Bottles, Cans and Jars

learn moreGlass-in-glass and metal-in-metal detection, capable of identifying small and irregular contaminants, with multi-beam imaging systems that ensure full container inspection without blind spots.

-

AI Top View Belt Optical Sorter

learn moreWidely applied to small particles and relatively flat products, ensuring effective detection of hair and micro-impurities, with reliable operation even in high-dust environments.

industries

Meat

Suitable for fresh and frozen meat, in both bulk and packaged forms.

Residual bone and bone fragments

Metal contaminants: broken needles/blades

Fat content analysis

Shape defects

Aluminum buckles

Damaged cut-resistant gloves

Glass, ceramics, metals

…

Seafood

Applicable to fresh and frozen seafood, both bulk and packaged.

Metal contaminant (e.g. fishhook)

Shell fragments and broken shells

Glass, stones, twigs, ceramics

Discoloration and shape detection

Cartilage inside lobsters

Canned seafood

Seal clip

…

Frozen Fruits

Suitable for sorting various frozen fruits by sorting impurities, discoloration, internal and external defects, shape recognition, mold, etc.

Off-color and discoloration

Misshapen, irregular, flattened fruits

Stems, hairs, small debris

Insect holes or worm-damaged fruits

Snails and insects

Moldy, broken, shriveled, cracked and incomplete fruits

Metal, ceramics, glass, stone, and sand embedded in berries

Fruit pit residue

…

Nuts

Suitable for various nuts—e.g., almonds, peanuts—whether in bulk or packaged form.

Shells, leaves, wood debris, insects

External and internal wormhole

Empty shells, half shells, double shells, cracked shells, closed shells

Single kernels, germination, mold

Shrinkage, shriveled, wrinkled, damaged

Residual skin and skin discoloration

Metal, ceramics, glass, stones

Plastic ties, straws, twigs

…

Bakery

Ideal for dough, bakery ingredients, and both bulk and packaged bakery products.

Metals, stones, glass

SUS sieve mesh wire

Deoxidizers/desiccants missing

Correct filling of brakery products

Damages, breaks, cracks

Deformed shapes

Seal clip

Mixed-in metal contaminants

...

Canned/Jarred/Bottled Food

Suitable for food in jars, bottles, cans, and Tetra Pak cartons, made from various materials such as glass, plastic, and metal.

Metal contaminants in metal cans

Glass contaminants in glass bottles

Vacuum detection

Dented/deformed cans

Filling capacity

Metal, stones, plastics, ceramics

Sus sieve mesh wires

Bone fragments

...

raymantech

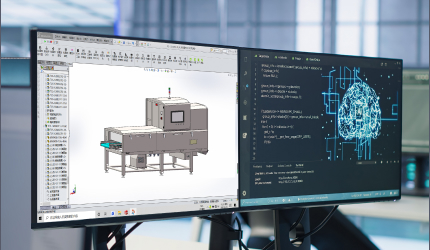

RaymanTech stands at the forefront of intelligent inspection and sorting solutions, pioneering cutting-edge X-Ray inspection, metal detection, checkweighing, and optical sorting technologies across the food, pharmaceutical, and industrial sectors. Driven by AI innovation and precision engineering, RaymanTech empowers manufacturers and processors across various food industries to enhance food safety, optimize food quality, and maximize production efficiency.

With deep industry expertise and continuous innovation tailored to market demands, RaymanTech's AI-powered whole-chain technology addresses critical pain points in all food industries and delivers smart and highly efficient and reliable inspection and sorting solutions to help food processors reach a higher lever of food safety and quality. Learn More >>

-

2015Founded In

2015Founded In -

160 +R&D Team

160 +R&D Team -

600 +Employees

600 +Employees -

200 +Intellectual

200 +Intellectual

Properties -

60 +Countries Served

60 +Countries Served

Expertise

-

Training

Our comprehensive training programs empower our partners with a deep understanding of RaymanTech's product series, key advantages, performance and operation. Furthermore, we provide valuable market penetration into best practices for industry-specific applications, enabling food processors to achieve the highest standards of food safety and quality.

Learn More >> -

Service

From pre-purchase consultation to post-installation optimization, RaymanTech provides a full-service solution to keep the inspection and sorting systems running at peak performance. With expert support, tailored training, and guided maintenance programs, we help our customers maximize efficiency, ensure compliance, and protect brand reputation.

Learn More >> -

Resources

With deep expertise in all food industries, RaymanTech delivers innovative inspection and sorting solutions. Contact us to access a wide range of resources and tools designed to enhance food safety, improve product quality, and optimize operational efficiency.

Learn More >>

Get in Touch!

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

.png)