AI + Ultra-HD: The Ultimate AI Optical Sorter for Wet Processed Meat Lines

In an era where food safety, consistency, and efficiency define success in the food processing sector, the processed meat industry stands at the forefront of technological innovation. Products like fried chicken nuggets, battered meat strips, sausages, and plant-based alternatives are not just convenience foods; they represent a multi-billion-dollar market driven by consumer expectations for high-quality, defect-free items. As global demand surges, manufacturers face mounting pressure to eliminate contaminants, ensure uniform appearance, and minimize waste—all while complying with stringent regulations. Optical sorting technology has become indispensable in addressing these demands, using advanced imaging and automation to inspect and sort products at high speeds.

Industry Pain Points: The Complexities of Optical Sorting Detection in Meat Processing

The processed meat sector is inherently challenging due to the biological variability of raw materials and the transformative nature of processing steps like breading, frying, and freezing. As quality standards evolve, enterprises must safeguard against issues that could compromise product integrity, such as foreign materials (e.g., plastic shards or metal fragments) or visual defects like burnt spots. Optical sorting, which employs cameras and sensors to analyze products in real-time, is increasingly vital on production lines. However, several persistent pain points hinder its effectiveness, leading to inefficiencies, higher costs, and potential recalls.

One primary difficulty lies in dead angle recognition. Processed meat items often exhibit irregular, non-uniform shapes—think of a chicken nugget with concave surfaces or folded edges. When illuminated, these contours can produce glare, reflections, or deep shadows, making it hard for standard cameras to capture complete images. Obscured areas, or "detection dead zones," may harbor defects that appear normal from a single viewpoint but reveal problems upon closer inspection. For instance, a hidden crack or embedded contaminant might evade detection, only to be discovered post-packaging, resulting in costly rework or consumer complaints. This issue is exacerbated in high-speed lines where products tumble or overlap, further complicating visibility. Labor shortages compound this problem, as manual inspection—once a fallback—becomes unreliable and expensive in an industry facing rising salary costs and workforce gaps.

A second major hurdle is the identification of fine, irregular defects. Processed meats are prone to subtle imperfections such as focal burns (charred spots from uneven cooking), skin tears, residual bone fragments, or minute foreign residues. These defects vary in shape, size, and color, often blending seamlessly with the product's natural hues—making them elusive to basic optical systems. For example, a small hair or discoloration might mimic the texture of breading, leading to false negatives (leakage) or positives (misjudgments) that disrupt operations. Traditional systems, limited by resolution and simplistic algorithms, struggle with these nuances, especially under variable lighting or when products are coated in oils or batters. In the broader food production context, waste from undetected defects is a significant issue, with optical sorting emerging as a key tool to mitigate it by precisely removing subpar items without discarding viable product. Moreover, regulatory pressures and food safety concerns amplify these challenges; a single contaminant can trigger recalls, damaging brand reputation and incurring financial losses.

Beyond these technical barriers, the industry grapples with broader systemic issues. The Meat Industry 5.0 paradigm emphasizes smart technologies to overcome labor shortages and enhance sustainability, yet implementation lags due to integration complexities and high initial costs. In 2025, food processing faces acute challenges like supply chain disruptions and escalating energy costs, where optical sorting must adapt to ensure consistent quality amid fluctuating raw material quality. For processed proteins, including meat and bone meal, maximizing protein content while removing impurities is crucial for value addition, but inconsistent detection leads to suboptimal yields. Robotic and automated systems are being explored to complement optical sorting, but without addressing core detection flaws, efficiency gains remain limited.

These pain points not only inflate operational costs—through increased waste, rework, and downtime—but also pose risks to public health. In high-risk sectors like processed meat, where bacterial contamination or allergens could lurk in defects, the stakes are extraordinarily high. As the market grows, with projections indicating a surge in demand for ready-to-eat meats, resolving these detection dilemmas is imperative for sustainable growth.

Our Advantageous Solutions: Performance and Innovation in Optical Sorting

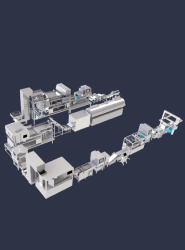

To surmount these obstacles, advanced optical sorting systems offer transformative solutions, blending cutting-edge hardware with intelligent software. Our approach centers on a ultra-high-definition (UHD) multi-perspective food-specific optical sorting machine, designed explicitly for the rigors of meat processing. This technology not only addresses dead angles and subtle defects but also enhances overall line efficiency, hygiene, and data-driven decision-making.

First, multi-perspective detection revolutionizes visibility by capturing up to five synchronized angles of each product. Unlike single-view systems, this setup provides a comprehensive 360-degree analysis, illuminating edges, undersides, and crevices to eliminate dead zones. For irregular shapes like meat strips or nuggets, multiple cameras ensure no defect hides in shadows or reflections. In practice, systems like Key Technology's COMPASS and VERYX sorters employ similar multi-sensor fusion, detecting color, size, shape, and structural anomalies to remove clumps, improper coatings, or foreign materials with precision. This results in near-zero leakage, boosting yield by up to 20% in protein processing lines.

Second, UHD super-high-definition imaging elevates resolution to pinpoint microscopic flaws. High-res cameras, often integrated with near-infrared (NIR) or multi-spectral sensors, discern fine hairs, slight color variances, or surface blemishes that evade standard optics. In processed meat, this means reliably spotting burnt spots or skin breaks, even if they match the product's tone. UHD systems achieve detection rates exceeding 99%, far surpassing manual methods.

Third, AI-powered intelligent recognition introduces adaptability through machine learning algorithms that self-train on product features. This allows the system to identify irregular, non-typical defects without predefined rules, minimizing false positives and negatives. For instance, AI can differentiate between a harmless texture variation and a genuine flaw, adapting to new product lines or seasonal changes in meat quality. In the food industry, AI enhances predictive maintenance and sorting speed, processing thousands of items per minute.

Finally, superior hygienic design ensures compliance with meat processing environments. Our systems are waterproof, dustproof, and easy to clean, featuring open architectures and sloped surfaces to prevent bacterial buildup. This is critical in wet, high-contamination settings, aligning with standards for frozen proteins and reducing downtime for sanitation.

In performance terms, these features deliver tangible benefits: reduced waste through precise sorting, cost savings via automation (eliminating manual inspectors), and enhanced sustainability by maximizing usable product. Case studies from the industry show processors achieving 15-25% yield improvements and fewer recalls, particularly in high-volume operations for nuggets or tenders. Market analyses highlight that despite challenges like competition and regulations, optical sorters are poised for growth, driven by innovations in AI and sensor tech.

Future Outlook: Embracing Optical Sorting for a Resilient Industry

As the processed meat industry navigates 2025 and beyond, optical sorters will play a pivotal role in overcoming pain points and capitalizing on opportunities. By integrating multi-perspective UHD imaging, AI, and hygienic designs, manufacturers can achieve unprecedented quality control, efficiency, and compliance. The shift toward Meat Industry 5.0, with its emphasis on robotics and data analytics, underscores the need for such technologies to address labor shortages and sustainability goals. Ultimately, AI optical sorting not only resolves detection dilemmas but also positions companies for long-term success in a competitive, consumer-driven market.

Related Articles

-

Dec-10-2025

Dec-10-2025Introduction to RaymanTech Optical Sorters for Farm Products and Food Processors

RaymanTech, as a leading provider of inspection and sorting solutions, has developed a comprehensive optical sorter portfolio that now serves both farm-product applications and food-processing environments. While farm-product sorters focus on capacity, adaptability, and raw-material variability, food-processor-grade sorters must also incorporate high IP protection, robust stainless-steel construction, sanitary design, and harsh washdown compatibility.learn more -

Dec-10-2025

Dec-10-2025The Essential Role of Raisins Optical Sorting Machines

Raisins present a unique set of challenges: they are naturally sticky, vary significantly in moisture content, and often arrive from the vineyard mixed with difficult-to-detect debris. As a cornerstone of the modern production line, a high-quality dried fruit sorting machine does more than just separate good fruit from bad; it protects brand reputation and ensures strict food safety compliance. Whether you are processing sun-dried Thompson Seedless or delicate Golden raisins, implementing an intelligent sorting solution is essential for operational efficiency.learn more -

Dec-10-2025

Dec-10-2025RaymanTech Whole-Chain Solution: A Deep Dive

Food safety and quality control demands have evolved dramatically. Modern food processors can no longer rely on spot-checks or isolated inspection points — contaminants, defects, and non-conformities can originate at any stage: raw ingredients, processing, or final packaging. RaymanTech’s Whole-Chain Inspection & Sorting Solutionlearn more

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057