Peanuts Optical and X-Ray Sorting Technologies

For processors, the challenge is evolving. It is no longer enough to just remove stones or discolored nuts. The modern production line must detect invisible threats—from internal mold (a precursor to Aflatoxin) to low-density contaminants like plastic ties. This guide explores how integrating peanut optical sorting and X-ray inspection creates a "zero-defect" defense system.

1. Peanut Optical Sorting

The critical step is surface inspection. Peanut optical sorting technology has evolved from simple color rejection to complex AI-driven decision-making.

How It Works

Modern optical sorters, such as those utilizing AI Deep Learning, don't just look for "dark spots." They are trained on millions of images to understand the texture of a peanut.

● Visible Spectrum: High-definition RGB cameras detect subtle color variations, such as mold (Aflatoxin risk), skin discoloration, and bleaching.

● Shape Recognition: The systems identify and eject broken, split, or shriveled kernels that degrade the visual quality of the final pack.

● Foreign Material: They excel at removing objects that look different from peanuts, such as cigarette butts, paper, or distinctively colored plastics.

Market Trend:

Recent search data indicates a surge in demand for "InGaAs" (Infrared) cameras paired with optical sorters to detect shell fragments that match the color of the nut meat—a common challenge in shelled peanut processing.

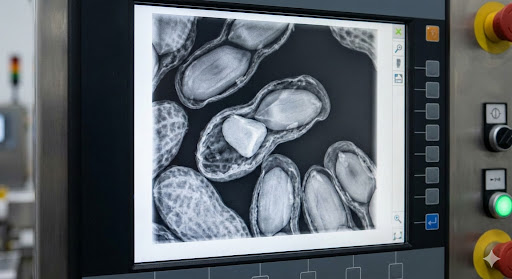

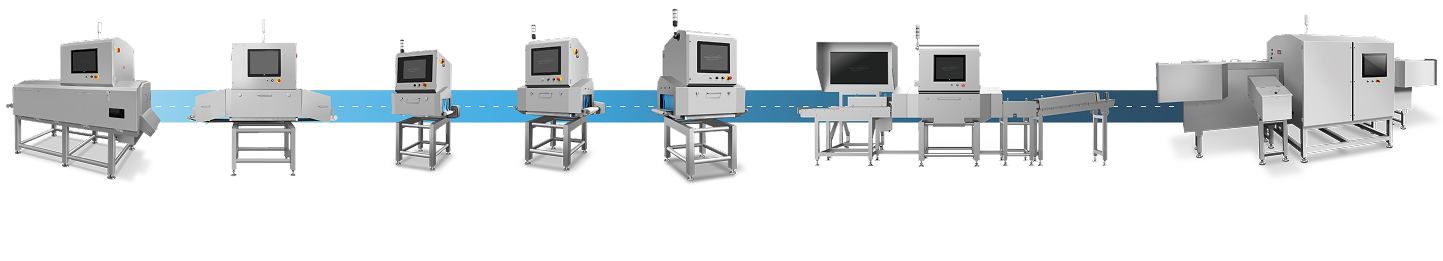

2. Combine X-Ray Inspection Methods

While optical sorters are the masters of the surface, X-ray inspection methods are the masters of density. This technology is indispensable because many dangerous contaminants look exactly like a peanut to a standard camera.

X-ray systems penetrate the product to reveal what lies beneath the shell or inside the kernel. This is the only technology capable of ensuring that a visually perfect in-shell peanut isn't actually empty or filled with a stone.

3. Optical vs. X-Ray: The Critical Differences

To build a foolproof line, you must understand exactly what each machine "sees." Based on the latest technical comparisons, here is how they differ in detecting specific threats.

The "Low-Density" Challenge

One of the most significant findings in modern sorting is the difference in handling low-density foreign objects.

● Optical Sorters struggle if the debris matches the peanut's color.

● X-Ray Inspection is the superior choice here. According to technical specifications, advanced X-ray systems can detect Low-density and Organic Contaminants including plastic ties, straws, and twigs. These items are often invisible to optical sorters but have a distinct density signature that X-ray algorithms can flag and reject.

Quality Control: The Germination Factor

For premium peanut products, internal quality is just as important as safety.

● Optical Sorters cannot see inside an intact shell or kernel.

● X-Ray Inspection is unique in its ability to monitor Quality Control metrics such as Germination (internal sprouting), shrinkage, and single kernel (empty shell) detection. By analyzing the internal density, the X-ray can confirm if a peanut has started to sprout inside the shell—a major defect for flavor and shelf life—without ever cracking it open.

4. The Future is Integrated: AI-Driven Processing

The most efficient processing lines in 2025 do not choose between these technologies; they layer them.

1. Surface Cleaning: Optical sorters remove the 90% of visible defects (discoloration, mold, broken skins).

2. Final Safety Check: X-ray inspection acts as the final gatekeeper, catching the plastic ties, straws, and twigs that slipped past the cameras, and identifying internal germination or hollow shells.

Leading manufacturers are now using Deep Learning to connect these machines. If the X-ray detects a spike in small stones, it can signal the pre-cleaning equipment to adjust settings automatically, creating a self-correcting "smart factory."

Frequently Asked Questions (FAQs)

Q1: Can optical sorters detect Aflatoxin directly?

No machine can "see" a chemical toxin. However, optical sorters are highly effective at removing the carriers of Aflatoxin—moldy and discolored peanuts. By removing these high-risk kernels, the overall Aflatoxin levels in the batch are significantly reduced.

Q2: Why is X-ray necessary if I already have a metal detector?

Metal detectors only catch metallic contaminants. They cannot detect glass, ceramic, stones, or high-density plastics. Furthermore, as noted above, only X-ray systems can detect germination and internal shrinkage inside the peanut, which are critical quality defects, not just safety hazards.

Q3: Is X-ray inspection safe for food products?

Yes. The X-ray energy used in food inspection is extremely low and does not make the food radioactive. It is a standard, FDA-approved method used globally for inspecting everything from nuts to baby food.

Q4: What is the hardest contaminant to detect in peanuts?

The hardest contaminants in peanuts are small, low-contrast foreign materials such as shell fragments, insect parts, hair, fine fibers, and tiny stones, because they closely resemble the peanuts in color, shape, or density and can easily be missed by standard inspection methods. Combining X-ray for density differences and AI-based optical sorting for color/shape differences is usually the most effective approach for peanuts.

Ready to Eliminate Contaminants from Your Line?

If your current quality control process is missing low-density contaminants like straws and twigs, or failing to catch internal germination, it may be time to upgrade your technology stack. Contact RaymanTech Now for more advice.

Related Articles

-

Dec-12-2025

Coffee Bean Optical Sorting: Advanced Solutions for Defect Removal

At RaymanTech, we specialize in intelligent, end-to-end inspection solutions that empower processors to achieve the highest grades of coffee. In this guide, we’ll explore how a Coffee Beans Color Sorting Machine works, the specific defects it removes at every stage, and how to choose the right system for your production line.learn more -

Dec-12-2025

Dec-12-2025RaymanTech X-ray Inspection Systems: The Complete Guide to a Smarter, Safer Production Line

When a single shard of glass, a fragment of bone, or an unnoticed plastic tie can trigger a multimillion-dollar recall and shatter consumer trust, food manufacturers can no longer rely on yesterday’s detection technology. RaymanTech has built an entire ecosystem of X-ray inspection solutions that go far beyond traditional metal detectors, delivering density-based, shape-aware, AI-enhanced inspection across every product format imaginable.learn more -

Dec-12-2025

Dec-12-2025Introduction to RaymanTech Optical Sorters for Farm Products and Food Processors

RaymanTech, as a leading provider of inspection and sorting solutions, has developed a comprehensive optical sorter portfolio that now serves both farm-product applications and food-processing environments. While farm-product sorters focus on capacity, adaptability, and raw-material variability, food-processor-grade sorters must also incorporate high IP protection, robust stainless-steel construction, sanitary design, and harsh washdown compatibility.learn more

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057