Safe Paws, Happy Hearts: Mastering Pet Food Safety with Advanced X-Ray Inspection

As pet owners increasingly view their companions as family members, the tolerance for foreign body contamination in pet food has dropped to zero. For manufacturers, ensuring food safety inspection of pet food products is not just about compliance; it is about protecting brand reputation and, ultimately, the lives of pets.

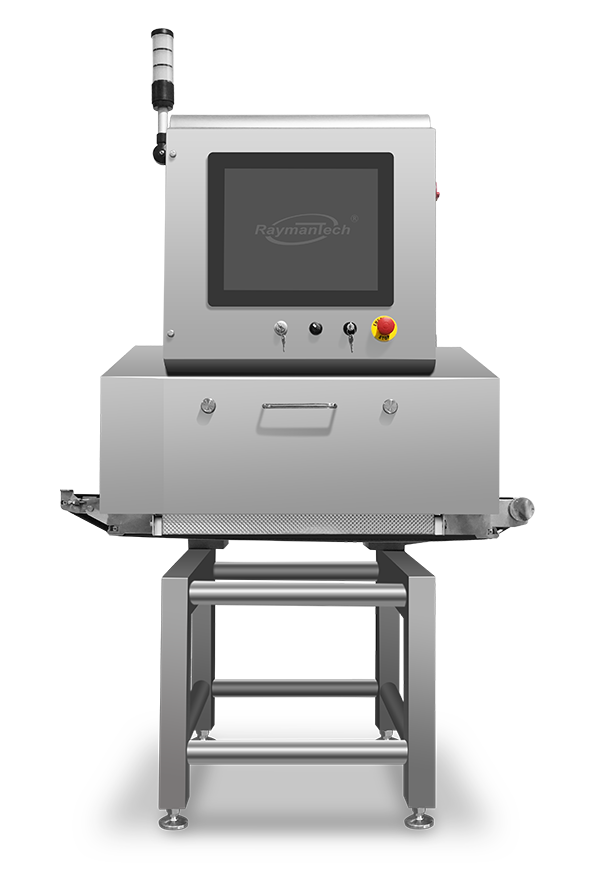

To meet these rigorous standards, producers are turning to next-generation technology. Pet food x ray inspection has emerged as the gold standard for detecting contaminants that traditional methods miss. In this guide, we explore how advanced pet food x-ray inspection systems—like RaymanTech’s AI and UHD solutions—are revolutionizing quality control across every category of pet nutrition.

The Hidden Dangers: What’s Really in the Bag?

Different types of pet food present unique safety challenges. Based on industry data and comprehensive contaminant analysis, we have categorized the specific risks associated with each production line.

Product inspection of pet food must address these specific vulnerabilities:

1. Dry Dog and Cat Food (Kibble)

The most common format, kibble, faces risks from machinery wear and raw material harvesting.

· Primary Contaminants: Metal (often from production line spare parts, repair welding slag, drilling, or stainless steel mesh wire), stone, and glass.

· Critical Defect: Missing Desiccants or Deoxidizers (essential for freshness).

2. Wet (Canned) Pet Food

High moisture content makes wet food difficult for metal detectors, but X-ray systems excel here.

· Primary Contaminants: Bone Fragments, Metal, Stone, Glass, Rigid Plastics, and Ceramics.

· Packaging Integrity: Non-standard shapes such as dented or deformed cans.

3. Frozen Pet Food (Raw & Cooked)

As the raw diet trend grows, so does the risk of bone remnants.

· Primary Contaminants: Bone Fragments are the top priority here. Also includes metal, stone, rigid plastics, and ceramics.

4. Pet Treats and Biscuits

Treats often have complex textures that can hide foreign bodies.

· Primary Contaminants: Bone Fragments, Stainless steel mesh wire, Metal, Stone, Glass.

· Critical Defect: Missing Desiccants or Deoxidizers.

5. Freeze-Dried Pet Food

High-value products require high-precision inspection.

· Primary Contaminants: Bone Fragments, Stainless steel mesh wire, Metal, Stone, Rigid Plastics.

· Critical Defect: Missing Desiccants or Deoxidizers.

6. Dehydrated Pet Food

Similar to freeze-dried, the drying process can introduce specific metallic contaminants.

· Primary Contaminants: Bone Fragments, Stainless steel mesh wire, Metal, Stone, Glass.

· Critical Defect: Missing Desiccants or Deoxidizers.

7. Pet Food Ingredients

Safety starts at the source.

· Meat Ingredients: High risk of Bone Fragments.

· Grain and Vegetable Ingredients: High risk of Stainless steel mesh wire, Metal, Stone, and Glass.

How RaymanTech Technologies Address These Risks

Standard inspection is often insufficient for the complex "product effect" of wet food or the low density of bone fragments. This is where RaymanTech’s specialized pet food x-ray inspection systems provide a decisive advantage.

1. AI-Powered X-Ray for Bone Detection

For Frozen, Wet, and Ingredient categories, bone fragments are a persistent threat.

· The Solution: RaymanTech’s Standard Dual Energy X-Ray Inspection System utilizes deep learning algorithms. Unlike traditional machines that rely solely on density differences, the AI is trained to recognize the specific shape and texture of biological contaminants.

· The Benefit: It effectively distinguishes between the pet food product and bone fragments (even low-density chicken bones), significantly reducing false rejects while ensuring safety.

2. UHD Systems for Fine Wires

In Dry Kibble and Dehydrated foods, thin wires from processing sieves are a major hazard.

· The Solution: The UHD (Ultra High Definition) X-Ray System offers superior resolution.

· The Benefit: It can detect minute contaminants like stainless steel mesh wire (often <0.3mm) that standard X-ray sensors might miss due to pixel limitations.

3. Metal Can and Glass Bottle Inspection

For Wet Canned Food, safety goes beyond foreign bodies.

· The Solution: Specialized X-ray systems for Cans, Bottles, and Jars.

· The Benefit: These systems simultaneously inspect for contaminants and verify packaging integrity, identifying dented or deformed cans and ensuring proper fill levels to prevent spoilage.

Frequently Asked Questions (FAQs)

To help manufacturers better understand the implementation of these systems, we have compiled answers to common questions regarding pet food x ray inspection.

Q1: Can X-ray inspection systems detect plastic in pet food?

A: Yes, but with conditions. X-ray systems are excellent at detecting rigid plastics (like pieces of conveyor belt or hard tools) because they are denser than the food product. However, thin, low-density soft plastics (like film wrappers) are harder to detect. RaymanTech’s AI-powered systems are pushing these boundaries, improving detection rates for difficult materials.

Q2: Is X-ray inspection safe for pet food?

A: Absolutely. The radiation dose used in food safety inspection of pet food products is extremely low and does not affect the nutritional value, flavor, or texture of the food. It is purely for inspection and does not make the food radioactive.

Q3: Why choose X-ray over metal detectors for wet pet food?

A: Wet pet food has a high "product effect" (conductivity) due to moisture and salt, which often triggers false alarms in metal detectors. Pet food x-ray inspection systems are based on density, not conductivity, making them immune to these issues and allowing them to detect non-metallic contaminants like glass, stone, and bone.

Q4: Can X-ray systems check for missing components in treat bags?

A: Yes. As noted in our defect table, ensuring the presence of desiccants or deoxidizers is critical for shelf life. X-ray systems can "count" items inside a sealed package and automatically reject bags where these essential components are missing.

Related Articles

-

Dec-02-2025

Dec-02-2025RaymanTech X-ray Inspection Systems: The Complete Guide to a Smarter, Safer Production Line

When a single shard of glass, a fragment of bone, or an unnoticed plastic tie can trigger a multimillion-dollar recall and shatter consumer trust, food manufacturers can no longer rely on yesterday’s detection technology. RaymanTech has built an entire ecosystem of X-ray inspection solutions that go far beyond traditional metal detectors, delivering density-based, shape-aware, AI-enhanced inspection across every product format imaginable.learn more -

Dec-02-2025

Dec-02-2025Introduction to RaymanTech Optical Sorters for Farm Products and Food Processors

RaymanTech, as a leading provider of inspection and sorting solutions, has developed a comprehensive optical sorter portfolio that now serves both farm-product applications and food-processing environments. While farm-product sorters focus on capacity, adaptability, and raw-material variability, food-processor-grade sorters must also incorporate high IP protection, robust stainless-steel construction, sanitary design, and harsh washdown compatibility.learn more -

Dec-02-2025

Dec-02-2025How Safe is X-ray Inspection of Food?

Consumers and manufacturers alike worry about contamination in food – broken glass, metal fragments, plastic or stone – entering a product and harming someone or prompting a recall. X-ray inspection systems have become a key solution: conveyors carrying packaged or unpackaged food pass through a shielded X-ray machine that “sees” inside each item. This technology complements traditional metal detectors and manual checks to catch a wider range of hazards. Importantly, extensive research and industry experience show that food X-ray inspection is extremely safe. Nearly everything we eat – from spices to snacks – is X-rayed at some point during production, and regulatory bodies (like the FDA) report “no known adverse effects” from the low-dose X-ray scans used in food plants.learn more -

Dec-02-2025

Dec-02-2025How Pepper Optical Sorting Machine Elevates Spice Quality

At RaymanTech, we understand these challenges. Our advanced Pepper optical sorting machine solutions utilize cutting-edge AI and Ultra-HD imaging to revolutionize pepper grading, ensuring that your black, white, and green peppers meet the most stringent international standards.learn more -

Dec-02-2025

Dec-02-2025Revolutionizing Fat Content Analysis in the Meat Industry: Advanced AI-Driven Solutions

In today’s highly competitive meat processing industry, accurate fat content detection is no longer optional—it’s a core driver of profitability, product consistency, and brand reputation. Fat ratio directly affects raw material yield, formulation costs, flavor profile, texture, and even regulatory compliance. For modern, high-throughput plants pursuing standardization and lean manufacturing, achieving fast, reliable, and non-destructive fat measurement has become a key success factor.learn more -

Dec-02-2025

Dec-02-2025The Essential Role of Raisins Optical Sorting Machines

Raisins present a unique set of challenges: they are naturally sticky, vary significantly in moisture content, and often arrive from the vineyard mixed with difficult-to-detect debris. As a cornerstone of the modern production line, a high-quality dried fruit sorting machine does more than just separate good fruit from bad; it protects brand reputation and ensures strict food safety compliance. Whether you are processing sun-dried Thompson Seedless or delicate Golden raisins, implementing an intelligent sorting solution is essential for operational efficiency.learn more -

Dec-02-2025

Dec-02-2025The Ultimate Guide to Lamb X-Ray Inspection

Lamb and mutton products hold a premium spot in the global meat market, prized for their flavor and nutritional value. However, ensuring these products reach the consumer free from contaminants is a complex challenge facing processors today. From tiny bone fragments hidden in ground meat to broken needles left behind from vaccinations, the risks are real.learn more -

Dec-02-2025

Dec-02-2025Why X-Ray is Superior for Chocolate Inspection

For manufacturers, ensuring that every bite is safe and perfect is not just a goal—it is a necessity. This is where x ray chocolate bars inspection technology becomes a critical asset. Here is a comprehensive guide to how X-ray inspection secures quality for both solid and filled chocolate products, powered by RaymanTech’s intelligent solutions.learn more -

_1.png) Dec-02-2025

Dec-02-2025Corn Sorting Solution for Modern Processing

In the competitive global grain market, consistency and purity are the currencies of trust. From raw harvesting to final packaging, ensuring that every kernel meets the highest standards is a challenge that manual labor can no longer sustain. This is where advanced corn optical inspection systems step in—transforming how yellow corn, white corn, and popcorn are processed, graded, and valued.learn more -

Dec-02-2025

Dec-02-2025RaymanTech Whole-Chain Solution: A Deep Dive

Food safety and quality control demands have evolved dramatically. Modern food processors can no longer rely on spot-checks or isolated inspection points — contaminants, defects, and non-conformities can originate at any stage: raw ingredients, processing, or final packaging. RaymanTech’s Whole-Chain Inspection & Sorting Solutionlearn more

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057