Overcoming Challenges in Large Package: Rayman Tech's AI X-ray Solutions for Meat Processing

Our AI X-ray Inspection System, tailored for high ...

More

X-ray inspection systems offer unparalleled detection of dense contaminants like metal and glass, boosting food safety. This capability is critical in the x ray food industry, as foreign materials are a leading cause of product recalls.

FDA: Foreign materials accounted for 30.8% of recalls.

USDA: Foreign materials comprised 37.9% of recalled food pounds.

However, this advanced capability requires significant investment and cannot detect low-density items like wood or hair.

Food manufacturers adopt X-ray inspection systems for several compelling reasons. These systems provide benefits that extend far beyond simple contaminant removal, touching on quality, efficiency, and brand integrity. They represent a strategic investment in modern food safety protocols.

An X-ray system's primary advantage is its exceptional ability to detect dense foreign bodies that other methods miss. It reliably identifies contaminants regardless of their magnetic properties, making it highly effective for finding metals, glass, calcified bone, and high-density plastics. The system's sensitivity, however, depends on the product's characteristics. Product density and thickness are crucial factors. Higher density or thicker products require more X-ray power, which can influence detection accuracy.

The effectiveness of detection varies by contaminant type:

Easy Detection: Ferrous metals, non-ferrous metals, and calcified bone are generally simple to find.

Moderate Difficulty: Stainless steel and aluminum wires are more challenging, with detection heavily influenced by product size.

Difficult Detection: Glass, stone, rubber, and plastic are the hardest to detect. Success depends critically on the product's density and uniformity.

For example, Boulangerie St Donat, a Canadian pastry manufacturer, integrated an X-ray system to enhance its detection capabilities for products in metallized packaging. The system improved both food safety and product traceability, demonstrating its value in a complex production environment.

Modern X-ray systems function as multi-purpose quality control centers. They perform numerous checks simultaneously, offering a complete view of product integrity inside sealed packaging. This capability moves them from a simple safety device to a comprehensive quality assurance tool. Manufacturers in the x ray food industry leverage this technology to verify multiple product attributes at high speeds.

Beyond finding contaminants, X-ray inspection systems can perform a wide range of quality checks:

Mass Measurement: They estimate product mass to identify overfilled or underfilled packages, ensuring weight consistency.

Component Count: The system verifies that the correct number of items are inside a package, such as cookies in a tray or sauce packets in a meal kit.

Seal Integrity: It inspects seals on pouches and trays to identify defects that could lead to spoilage or leakage.

Product and Package Defects: It can spot broken or misshapen products, find missing caps on bottles, and identify container deformities.

Automating the inspection process with X-ray technology delivers significant gains in operational efficiency. These systems operate at high speeds without fatigue, reducing the need for manual checks. This automation directly lowers labor costs and minimizes the risk of human error.

X-ray systems create a powerful data feedback loop. They scan products, analyze for defects in real-time, and provide data that allows operators to make immediate process adjustments. This cycle of scanning, analysis, and feedback ensures continuous quality improvement.

The data generated by X-ray systems is a valuable asset for process optimization. Manufacturers can access and analyze key production metrics, including:

Rejection rates and timestamps

Time-stamped X-ray images for precise traceability

Critical Control Point (CCP) data for HACCP compliance reports

This information helps identify recurring issues on the production line, enabling engineers to find root causes and implement corrective actions. It also supports predictive maintenance by tracking performance trends, which helps anticipate equipment failures and reduce costly downtime.

Ultimately, the most significant benefit of X-ray inspection is the powerful protection it offers a company's brand. A single product recall can cause immense financial damage and erode consumer trust that took years to build. By catching contaminants and quality defects before products leave the facility, X-ray systems act as a final line of defense.

This proactive approach to safety provides consumers with an assurance of quality and builds brand credibility. Companies that invest in advanced inspection technology demonstrate a clear commitment to consumer health. This investment often yields a strong return. Preventing just one major recall, which can cost millions, allows an X-ray system to pay for itself many times over. Most systems achieve a full payback within 12 to 36 months by reducing waste and avoiding costly recalls.

Many leading food companies rely on X-ray inspection to protect their customers and their reputation.

| Company | Industry/Product | X-ray System | Defect Detected |

|---|---|---|---|

| Maple Leaf Foods (Canada) | Poultry processing | Ishida IX-G2 | Low-density foreign bodies |

| Smithfield Murray (UK) | Fresh chicken | Ishida IX-G2-F | Bone fragments and other contaminants |

| Soto Organic Veggie (GER) | Plant-based ready meals | Ishida X-ray | Product integrity and weight control |

| Thymos (SLV) | Spice production | Ishida X-ray | Foreign objects |

By ensuring product safety and consistency, X-ray inspection helps secure long-term brand loyalty and market leadership.

While X-ray inspection offers powerful advantages, manufacturers must also weigh its significant limitations. These drawbacks involve high costs, technical constraints, and operational complexities. A thorough understanding of these challenges is essential for making an informed decision about implementing this technology.

The primary barrier to adopting X-ray inspection is the substantial financial commitment. The initial purchase price for these systems is high, representing a major capital expenditure for many companies. Costs vary widely based on the system's capabilities and sophistication.

| System Type | Price Range |

|---|---|

| Entry-level | $60,000 to $120,000 |

| Advanced | $150,000 to $500,000+ |

For startups or small to medium-sized enterprises (SMEs), more cost-effective options exist. For example, some automated X-ray machines from manufacturers like Guangdong Jindun Electronic Technology Co., Ltd. start around $11,999, offering a more accessible entry point.

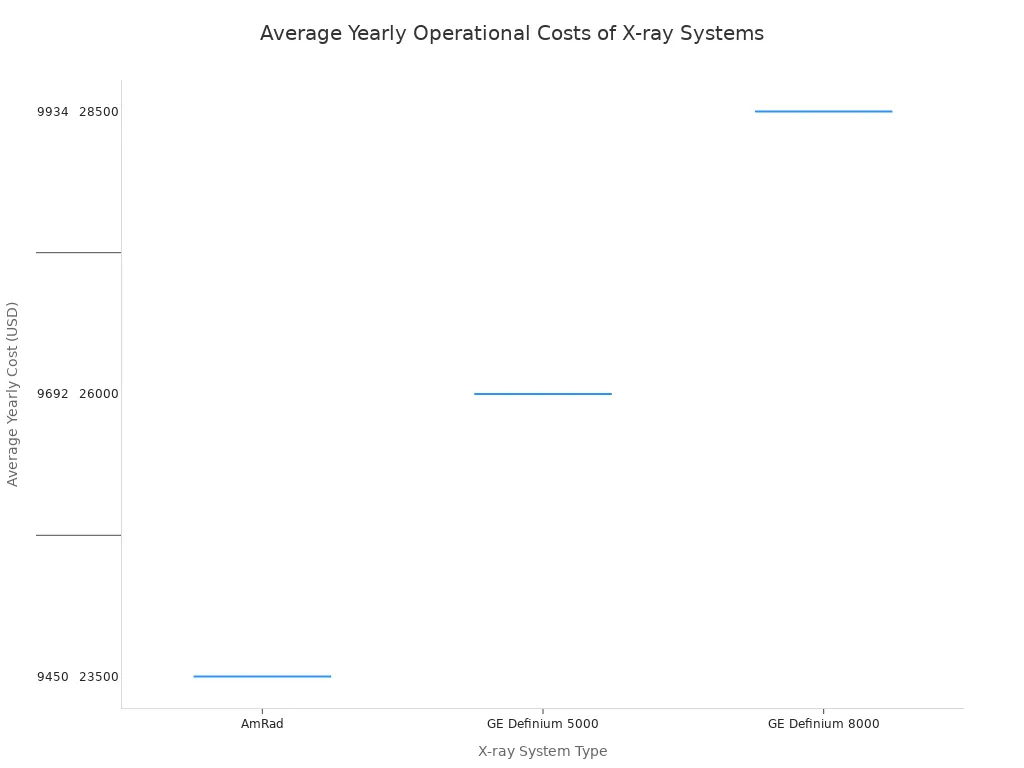

Beyond the initial purchase, ongoing operational costs add to the total cost of ownership. These expenses are not trivial and require careful budgeting.

Ongoing operational costs include regular maintenance, unexpected repairs, electricity usage, and consumables. Digital X-ray systems, despite a higher upfront cost, can reduce consumable expenses over time.

Several factors influence these recurring costs:

Age of System: Older units may have lower service costs due to wider parts availability.

Location: Travel expenses for service engineers are factored into maintenance quotes.

Parts: The cost of replacement parts, especially proprietary components from the Original Equipment Manufacturer (OEM), can be high. X-ray tubes, for instance, eventually require replacement at a cost of $3,000 to $9,000.

Service Contracts: Annual service contracts typically range from 5-10% of the system's purchase price.

The average yearly operational costs can differ significantly between models, as shown below.

A fundamental limitation of X-ray technology is its inability to detect low-density contaminants. The system works by identifying differences in density between the food product and a foreign object. If a contaminant has a density similar to or less than the food, the X-ray system cannot distinguish it.

This principle of "relative absorption" means that many common contaminants are effectively invisible to X-rays. These materials include:

Hair

Insects

Wood fragments

String

Low-density plastics and thin plastic films

Soft foam materials

These organic materials consist of carbon, hydrogen, and oxygen atoms, much like the food products themselves. With no significant difference in bulk density, the contaminant "looks exactly like food" on the X-ray image. A general rule is that if a contaminant floats on water, an X-ray system will likely not detect it, as detection requires the foreign body to be denser than the product. This is why the x ray food industry often uses X-ray systems in combination with other inspection methods to create a more comprehensive safety net.

The accuracy of X-ray inspection is highly dependent on the characteristics of both the product and its packaging. Variations in product shape, density, and texture can create a "product effect" that complicates detection and can lead to false rejections.

Frozen foods, for example, often have wide variations in density and structure, which can obscure small or low-density contaminants. Similarly, inspecting bulk materials with inconsistent particle sizes and shapes requires advanced systems that can differentiate between natural product variations and actual foreign objects. The sensitivity of detection is directly impacted by product density. For instance, finding glass is easier in low-density bread than in dense hard cheese because the density difference is greater.

Packaging also plays a critical role.

Glass and Ceramic: These materials have a wide range of densities and shapes. Operators must calibrate the system's resolution to account for these variations to avoid mistaking the container for a contaminant.

Plastic: Low-density plastic has a minimal effect, but thicker or denser plastics will appear on the X-ray image. The system's software must be configured to account for the packaging's thickness and density.

Paper and Cardboard: These low-density materials generally do not interfere with inspection unless they contain other materials, like plastic inner bags.

Modern X-ray machines use high-resolution detectors and advanced image processing algorithms to manage these complexities. However, they still require careful calibration to maintain high accuracy and minimize false positives.

Operating and maintaining an X-ray inspection system is not a simple task. It requires a workforce with specialized skills and a company-wide commitment to regulatory compliance. Employees who work with this equipment need comprehensive training to ensure both operator safety and system effectiveness.

Key training areas include:

Radiation Safety: All personnel working near the equipment must understand how to operate it safely. This often involves appointing and certifying a dedicated Radiation Safety Officer (RSO).

Operator Training: Operators need courses on proper equipment handling, software operation (like Simultask™), and basic troubleshooting to maximize machine uptime.

Maintenance and Repair: Technical staff require advanced training to perform equipment maintenance, diagnose complex problems, and conduct repairs. OEM certifications can promote self-sufficiency and reduce downtime.

Beyond training, staff must possess a specific skill set to manage these systems effectively. Proficiencies in equipment maintenance, quality control analysis, and complex problem-solving are essential. This need for a highly skilled team adds another layer of cost and complexity to the implementation of X-ray inspection technology.

X-ray systems perform a variety of critical tasks beyond basic safety checks. Manufacturers use this technology to find contaminants, verify product specifications, and ensure overall package integrity. These applications make X-ray inspection a versatile tool for modern quality control.

The primary function of an X-ray system is detecting dense foreign objects inside sealed packages. The system works by identifying density contrast. Contaminants like metal, glass, or stone absorb more X-rays than the surrounding food, causing them to appear as darker shapes on an image. This method effectively finds many common foreign bodies, including:

Metal fragments and needles

Glass shards and stones

High-density plastics and bone

Personal effects like jewelry or buttons

Recent recalls have involved plastic pieces in frozen meals and rocks in baked goods, highlighting the importance of this capability.

X-ray inspection also ensures product consistency and prevents costly errors. Systems can accurately measure container fill levels to identify underfilled or overfilled packages. Operators position a narrow X-ray beam at the desired fill height. If a container is properly filled, the product blocks the beam. An underfilled container allows more radiation to reach the detector, triggering an alert. This process guarantees that consumers receive the correct product amount while minimizing waste for the manufacturer.

Many products in the x ray food industry contain multiple items, and X-ray systems confirm package completeness. The technology can count components inside a sealed box, ensuring a variety pack or meal kit contains all its intended items.

X-ray systems can identify broken products, perform component counting, and check for voids, making them ideal for large cases containing multiple individually-wrapped products.

Furthermore, these systems spot physical defects that compromise quality. They can detect issues like cracked cookies, broken pasta, or chips in glass bottles, ensuring that only intact products reach the consumer.

Choosing the right inspection method requires comparing X-ray technology against other common systems. Each has distinct advantages depending on the specific production needs and potential contaminants.

The primary difference between these two systems lies in their detection technology. Metal detectors create an electromagnetic field and identify disruptions caused by metallic objects. X-ray systems, however, use advanced imaging to find contaminants by analyzing density differences within a product.

This technological distinction defines their capabilities:

Metal Detectors: They excel at finding ferrous, non-ferrous, and stainless steel contaminants. However, they cannot detect non-metallic items like glass, stone, or bone. They are a cost-effective solution when metal is the only major concern, with a lower initial purchase price and total cost of ownership.

X-Ray Systems: These systems detect a much wider range of foreign bodies, including metals, glass, and high-density plastics. They are essential for the x ray food industry when dealing with products in metallic packaging, which renders metal detectors ineffective.

While a metal detector is a valuable tool for a specific risk, an X-ray system offers broader protection against a more diverse set of potential contaminants.

Automated X-ray inspection provides significant advantages over manual visual checks, primarily in speed and consistency. Human inspectors are limited by fatigue and subjectivity, which can lead to errors and slower throughput.

In contrast, X-ray systems offer objective, high-speed performance.

Speed: Automated systems can inspect up to 600 units per minute, a rate impossible for a human to match.

Consistency: X-ray machines perform the same check every time, removing human error and ensuring a consistent quality standard. They operate with a target false reject rate of less than 3%.

While manual inspection offers flexibility for low-volume or complex-shaped products, it cannot scale for modern, high-speed production lines. X-ray automation delivers the reliability and efficiency required for comprehensive brand protection.

X-ray inspection provides critical advantages for food safety and quality assurance. Manufacturers must carefully consider the high costs and detection limitations for low-density items. Ultimately, the investment is a key part of a modern quality control strategy that protects consumers and secures long-term brand trust.

Yes, food remains completely safe after inspection. The extremely low radiation levels do not alter the food's taste, texture, or nutritional value, posing no risk to consumers.

X-ray systems effectively detect all metals, including ferrous, non-ferrous, and stainless steel. Their density-based technology works reliably even when products are inside foil or metallized film packaging.

These systems require regular maintenance for peak performance and safety compliance. Annual service and eventual parts replacement, like the X-ray tube, are necessary operational costs for manufacturers.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Automatic recognition and rejection, fish bone ins...

UHD X-Ray detector, AI large model, all food indus...

Ultra-fine contaminants detection, UHD X-Ray detec...

Glass-in-glass / Metal-in-metal inspection, small ...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Our AI X-ray Inspection System, tailored for high ...

MoreAs pet owners increasingly view their companions a...

MoreIn the fast-paced world of food production, ensuri...

MoreAs global demand for premium, safe meat products ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Control ManagerThis X-ray inspection system has revolutionized our food safety protocols. The detection accuracy for contaminants in packaged snacks is exceptional, significantly reducing our risk of product recalls.

Sarah Chen

Production SupervisorAs someone working in meat processing, I appreciate how this X-ray machine reliably detects bone fragments and metal contaminants while maintaining our production speed. The user interface is intuitive for our operators.

David Thompson

Food Safety DirectorImplementing this X-ray technology in our frozen food facility has been a game-changer. It consistently identifies foreign materials in our vegetable products with impressive precision, giving us complete confidence in our quality assurance.

Jennifer Williams

Bakery Operations ManagerThe X-ray system has been invaluable for detecting foreign objects in our baked goods. While the initial setup required some training, the long-term benefits for product safety and customer trust make it absolutely worthwhile.