Principle of X-ray Inspection Machines in the Food Industry

X-ray inspection machines have become indispensabl...

More

Advanced X-ray technologies offer comprehensive quality assurance, moving beyond simple metal detection. Foreign object contamination accounted for 11.4% of food recalls between 2020 and 2024, driving market growth. The foreign material segment for an inline x ray machine in food industry is forecasted to expand at an 8.15% CAGR.

Adopting these trends enables food manufacturers to enhance brand protection, improve product quality, and boost operational efficiency.

Modern food production demands inspection capabilities that see what traditional systems cannot. Advanced X-ray technologies are meeting this need by moving far beyond simple metal detection to identify a wider range of foreign materials with unprecedented accuracy.

Dual energy X-ray technology, also known as Material Discrimination X-ray (MDX) or PXT™, represents a significant leap forward. This technology works by capturing two images simultaneously at different energy levels. It analyzes how materials absorb these different energy spectra, allowing the system to differentiate items based on their chemical composition, not just their density. This makes an inline x ray machine in food industry exceptionally effective at identifying foreign bodies even in products with complex or varying densities, like a bag of trail mix.

Single-energy systems often struggle to find low-density contaminants like plastic, rubber, or wood. Dual energy technology overcomes this challenge by enhancing the contrast between the food product and the foreign object. This allows for the reliable detection of materials previously considered invisible to X-ray inspection.

Dual energy excels at inspecting products with 'busy' X-ray images, where high variations in product density would normally hide contaminants.

Common applications include finding:

Rubber pieces in packaged salads

Stones in leafy greens

Plastic fragments in baked goods

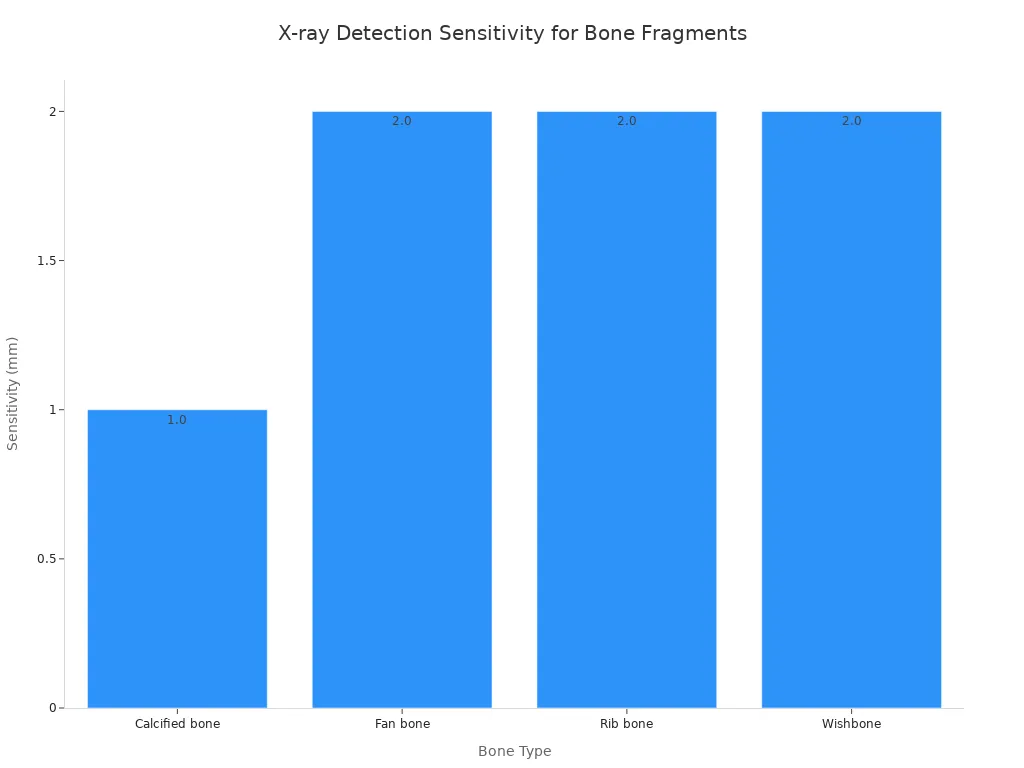

For the meat and poultry industry, bone detection is a critical safety measure. Advanced dual energy systems deliver superior performance, identifying calcified bone fragments as small as 1.0 mm. This enhanced sensitivity significantly improves product safety.

Similarly, glass-in-glass detection is a common challenge that these systems solve. While glass density makes it detectable, a shard's orientation can hide it from a single X-ray beam. A modern inline x ray machine in food industry often uses a second X-ray source, positioned at a 90-degree angle, to provide a different view and ensure even unfavorably oriented shards are found.

Artificial intelligence (AI) and machine learning are elevating X-ray inspection from a detection tool to an intelligent quality assurance partner. These technologies enable systems to learn, adapt, and make decisions with a level of precision that surpasses traditional programming.

AI-powered systems use deep learning to analyze vast amounts of image data, continuously refining their detection capabilities. Unlike static systems, they learn to recognize complex patterns and adapt to new contaminants with minimal human intervention. This allows an inline x ray machine in food industry to perform tasks that were previously impossible.

Adaptive Learning: Algorithms learn from new data, improving their ability to identify emerging threats over time.

Enhanced Differentiation: AI excels at analyzing 'busy' images, accurately distinguishing contaminants from acceptable product variations based on subtle differences in texture and density.

Broader Detection: It enables the identification of a wider range of contaminants, including low-density materials that traditional systems often miss.

A major benefit of intelligent image analysis is the significant reduction in false rejects. False rejections are a primary source of food waste and can cost a single production line over $15,000 annually.

By accurately distinguishing between a true defect and a natural product variation—like caked-on dough versus a normal bun dimple—AI-driven systems prevent sellable products from being discarded.

This precision minimizes unnecessary waste and boosts throughput, directly improving operational efficiency and protecting the bottom line.

AI is also transforming how manufacturers maintain their equipment. Predictive maintenance uses ongoing data analysis to forecast component failures before they happen, shifting maintenance from a reactive to a proactive strategy.

Industrial Internet of Things (IIoT) sensors continuously monitor the health of critical components like X-ray generators.

Machine learning algorithms analyze this data to detect anomalies and predict potential failures.

The system alerts operators to schedule maintenance, preventing unexpected breakdowns.

This approach delivers documented benefits, including a 5-15% reduction in facility downtime and a 5-20% increase in labor productivity.

Advanced hardware is only part of the equation. Modern X-ray systems pair powerful detection with sophisticated software, making the technology more accessible and manageable than ever before. These enhancements focus on simplifying operations, reducing human error, and turning raw data into actionable intelligence.

Today's X-ray systems feature intuitive, smartphone-like user interfaces. Operators can use familiar gestures like pinch-to-zoom and swiping to navigate screens and analyze images. This user-friendly design dramatically reduces the learning curve.

An intuitive interface minimizes operator errors and shortens training time. This allows new staff to become proficient quickly, ensuring operational continuity.

By simplifying command structures and providing clear visual guidance, these systems help prevent costly mistakes and improve overall production quality. The focus on cognitive ergonomics ensures operators can manage the system efficiently without extensive memorization.

Manual product setup is often time-consuming and prone to error. Modern systems solve this with automated features. A "1-Pass Product Setup" mode, for example, allows an operator to configure the system for a new product by running just a single sample. The software automatically optimizes detection settings, ensuring consistent performance and freeing up valuable operator time. This automation streamlines product changeovers and boosts line efficiency.

Networked X-ray systems provide powerful tools for compliance and process improvement. They centralize data from multiple inspection points into a single, accessible repository. This capability offers several key advantages:

Audit Readiness: Teams can instantly generate reports for internal or external audits, demonstrating compliance with standards like BRCGS Food Safety.

Improved Traceability: All inspection images and activity logs are securely stored, providing a complete record for any future investigation.

Actionable Insights: Plant managers can analyze data to identify performance trends, pinpoint inefficiencies, and drive continuous improvement across the entire enterprise.

Modern X-ray inspection extends beyond a single checkpoint, becoming a fully integrated part of the production process. This integration provides comprehensive quality control from raw materials to the final packaged product.

Inspecting raw materials at intake is a critical first line of defense. This upstream approach offers several advantages:

It protects downstream processing machinery from damage caused by hard contaminants.

It removes foreign materials like glass, stone, and metal fragments before they enter production.

It allows for non-destructive analysis of material composition, such as measuring the chemical lean (CL) or fat content in meat to optimize batches.

Effective quality control requires strategic placement of inspection systems. A thorough Hazard Analysis and Critical Control Point (HACCP) assessment helps identify the most effective points. For example, inspecting sausages early in the process removes contaminants before adding further value. Placing a system after freezing stabilizes product density, improving detection accuracy.

The role of an inline x ray machine in food industry is to create a network of quality checkpoints. Integrating systems at multiple points requires careful planning and regular maintenance. Well-maintained and calibrated systems can boost defect detection rates by up to 95%, ensuring consistent performance. This transforms the inspection process into a proactive quality assurance strategy.

An inline x ray machine in food industry performs simultaneous quality checks beyond contaminant detection. It verifies product mass to prevent underfilled or overfilled packages, reducing product giveaway. These systems can measure fill levels with variations as small as 1.0 ml. They also ensure seal integrity by identifying trapped product particles as small as 1mm that could compromise shelf life.

The evolution of X-ray inspection extends beyond technology to include new business models and operational strategies. These innovations make advanced systems more accessible, cost-effective, and adaptable, empowering manufacturers to optimize their quality assurance programs.

High upfront costs are no longer a barrier to adopting advanced inspection technology. Rental and subscription models offer flexible alternatives to outright purchasing, allowing companies to access state-of-the-art equipment as an operating expense. This approach provides predictable monthly costs and often includes maintenance and service.

| Feature | Renting an X-ray System | Subscribing to an X-ray System |

|---|---|---|

| Upfront Costs | Lower upfront costs | Low or no upfront cost |

| Maintenance | Often included in the agreement | Typically included in the subscription |

| Upgrades | May require a new agreement | Often includes technology upgrades |

| Financial Impact | Operating expense | Operating expense |

When contamination occurs, product reclaim services offer a sustainable solution. Instead of discarding an entire batch, manufacturers can use these specialized services to salvage valuable product.

Automated systems remove contents from packaging.

Recovered contents can be reused, resold, or disposed of properly.

Packaging materials are collected for recycling.

This process reduces material waste, protects brand integrity, and improves overall line performance.

Smart manufacturers now evaluate equipment based on its Total Cost of Ownership (TCO), not just the initial purchase price. TCO provides a complete financial picture by accounting for all expenses over the system's entire lifecycle. Key factors include:

Running costs like power and compressed air.

Service, spare parts, and operator training.

Downtime risks from part changes or software issues.

Analyzing TCO helps businesses make strategic investments that lower long-term expenses and boost profitability.

Modern X-ray systems feature modular and scalable designs. This approach provides unmatched agility, allowing businesses to adapt their inspection capabilities as production needs change. Modular components enable easier upgrades, faster maintenance, and customized configurations. This flexibility reduces costs and allows engineering teams to focus on innovation rather than rework, giving growing companies a significant competitive advantage.

The convergence of dual energy, AI, and user-friendly software has transformed X-ray inspection into a cornerstone of modern food quality assurance. These emerging trends make advanced inspection technology more powerful and accessible than ever before.

Companies like The Stephano Group successfully use an inline x ray machine in food industry to improve detection and lower costs. By embracing this evolution, food manufacturers secure a competitive advantage through unparalleled safety, quality, and efficiency.

Dual energy technology uses two X-ray beams. It differentiates materials by chemical composition, not just density. This improves detection accuracy in products with varying textures and densities.

AI enhances image analysis for better contaminant recognition. It reduces false rejects and enables predictive maintenance. This minimizes downtime and improves overall operational efficiency.

Yes, advanced X-ray systems detect a wide range of contaminants. They find low-density materials like plastic, rubber, wood, glass shards, and even small bone fragments. ✅

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Chicken bone inspection, global poultry AI databas...

Uneven and overlapped product detection, thin & lo...

Recommedation: Chili, walnut, peanuts, soybeans, c...

Recommedation: Chili, walnut, peanuts, soybeans, c...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

X-ray inspection machines have become indispensabl...

MoreAs pet owners increasingly view their companions a...

MoreConsumers and manufacturers alike worry about cont...

MoreIn the fast-paced world of food production, ensuri...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Assurance ManagerThis inline X-ray machine has revolutionized our contamination detection process. The sensitivity is outstanding, and integration with our production line was seamless. False rejects are minimal compared to previous systems.

Sarah Chen

Production SupervisorExcellent detection capabilities for metal, glass, and stone contaminants. The user interface is intuitive, and maintenance requirements are low. Has significantly improved our product safety standards.

David Thompson

Plant ManagerReliable performance in detecting foreign materials in our packaged meals. The automated rejection system works flawlessly. Only minor issue was the initial calibration, but technical support was excellent.

Jennifer Williams

Food Safety SpecialistOutstanding investment for our meat processing facility. Detects even the smallest bone fragments we previously missed. The data logging feature helps tremendously with our compliance documentation.