Meat

Applicable to fresh and frozen meat, both bulk and packaged, for foreign object detection (e.g., needles, blades), residual bone detection, fat analysis, color and shape sorting, packaging seal, and canned meat product inspection.

REQUEST A QUOTE

Capabilities

-

Safety: Bones & Metal

In meat processing, the primary safety concerns are residual bones and metal fragments. Mechanical cutting can leave behind tiny bone pieces—especially in poultry, pork, and beef—while broken injection needles or cutting blades are common sources of metal contamination. Additionally, equipment wear or human error can introduce metal shavings, tool fragments, or plastic particles into the product.

AI UHD and Dual-Energy X-ray systems precisely detect and remove these contaminants, including minute bone and metal fragments, ensuring product safety and quality. By reducing manual inspection and improving production efficiency, these systems protect downstream equipment, lower operating costs, prevent consumer complaints, and help manufacturers meet stringent regulatory standards while safeguarding brand reputation. -

Quality Upgrade

Variations in raw materials and operational errors can cause product quality issues such as discoloration, deformation in processed meat products, packaging seal defects, and over- or under-filling in meat cans.

By integrating AI X-Ray inspection and AI optical sorting technologies, these issues can be effectively resolved. AI X-Ray inspection ensures proper sealing and accurate filling, while AI optical sorting continuously detects and removes products with color or shape defects. Together, they enhance product consistency and quality, improve production efficiency, reduce manual inspection costs, and strengthen overall brand image. -

Fat Content Analysis

In the meat industry, X-Ray fat analysis technology accurately measures fat ratios to ensure each batch meets quality standards and maximizes the value of ground meat and cuts. It also supports meat grading, allowing producers to classify products by fat content, determine grade and market value, and meet diverse customer demands.

X-Ray inspection offers fast, precise, and non-destructive fat measurement while simultaneously detecting bone fragments. This whole-chain solution enhances production efficiency, reduces costs and lean meat waste, optimizes product formulations, ensures compliance, and strengthens market competitiveness.

whole chain solution

Meat Industry

• Bone Fragments

• Broken Needles/Blades

• Fat Content Analysis

• Color/Shape Defects

• Aluminum Buckles

• Damaged Cut-Resistant Gloves

• Metals, Glass, Ceramics

• Seal Clip

Industrial Applications

Explore by industry - access for more information.

-

Chicken Breasts

More information -

Chicken Thigh

More information -

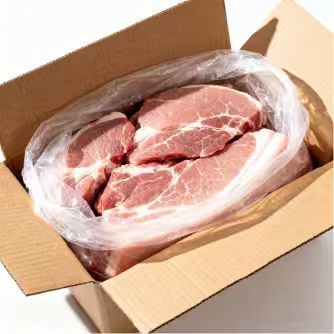

Boxed Meat

More information -

Breaded Nuggets

More information -

Steak

More information -

Hamburger Patties

More information -

Ground Beef/Pork

More information -

Meat Block

More information -

Spam

More information -

Bacon

More information -

Salami

More information -

Jerky

More information

Get in Touch!

For your meat inspection & sorting solutions!

Contact

For your meat inspection & sorting solutions!

Related Machines

X-Ray Inspection Systems

Optical Sorting Systems

-

Dual Energy X-Ray for Bone

· Bone detection

· Thin contaminant detection

· Low density contaminant detection

· IP69K rating

-

X-Ray for Fat Content Analysis

· Fat Content Analysis

· Thin Contaminants Inspection

· Low Dense Contaminants Detection

· Hygienic Design

-

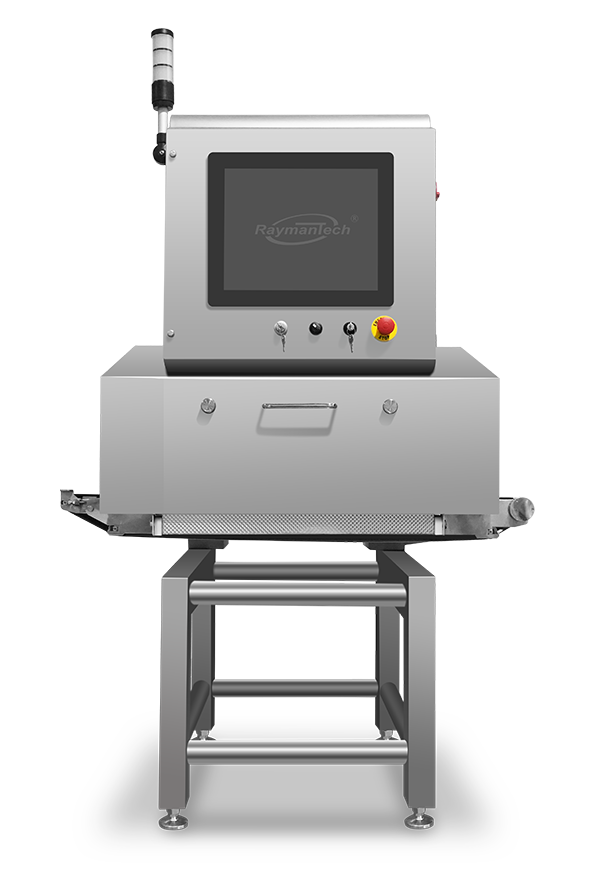

UHD X-Ray System

AI-powered UHD detector technology

Adaptable resolution technology

Ultra-fine contaminant inspection

IP67 for inspection tunnel

-

AI Medium Speed Sorter

.png)

Contaminants and defects sorting

Tiny impurity (hair) sorting

For wet and high-dust environments

For fragile or delicate products

-

AI Multi Beam Sorter

For dry/wet/frozen materials

Multi-view imaging

-

AI Top View Sorter

For small particles/flat products

Top single, double, or triple view

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

© 2015-2025 RaymanTech - Privacy Policy - Term of Use