How a Pistachios Optical Sorting Machine Guarantees Quality and Purity

Pistachios are a premium, high-value commodity. Co...

More

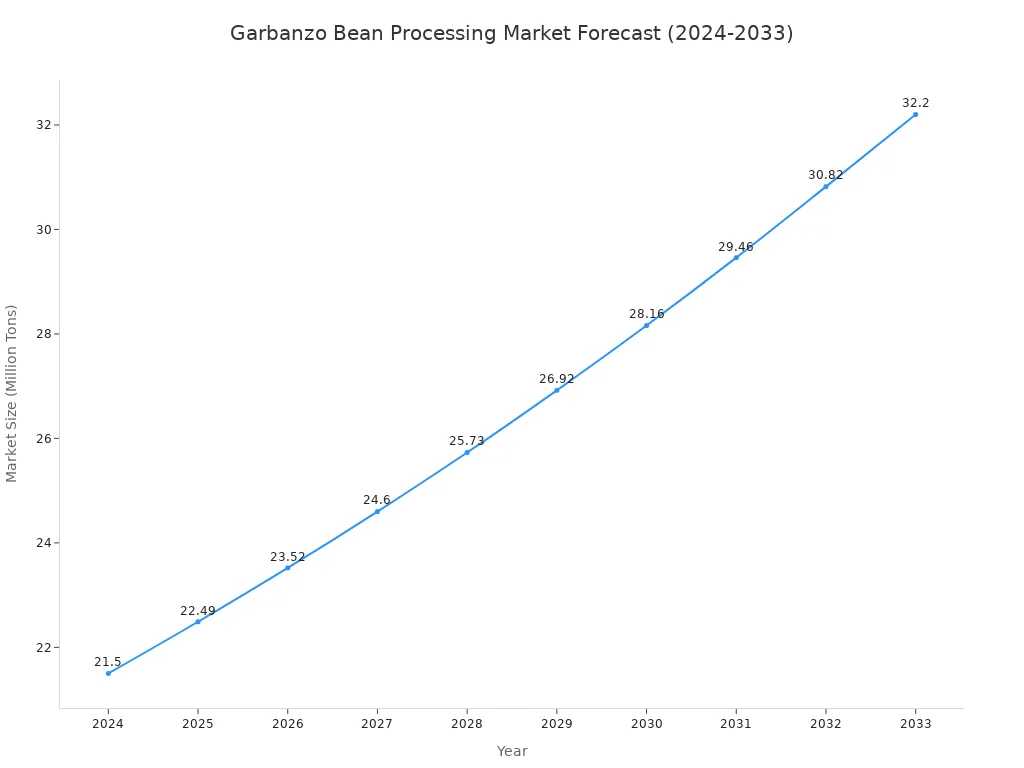

The garbanzo bean processing market shows significant growth. This expansion increases the demand for an efficient garbanzo beans sorting machine.

| Metric | Value |

|---|---|

| Market Size in 2024 | 21.5 Million Tons |

| Forecast Period | 2025-2033 |

| CAGR (2025-2033) | 4.57% |

| Market Forecast in 2033 | 32.2 Million Tons |

Large-scale operations often select Bühler for its superior purity standards. Conversely, Metak provides a cost-effective solution for small to medium-sized businesses. The decision balances Bühler’s advanced sensor technology against Metak’s performance-to-price ratio.

The core function of any optical sorter is to deliver a clean, high-quality final product. A machine's performance directly impacts profitability by maximizing yield and meeting stringent buyer specifications. Here, we analyze how Bühler and Metak stack up in defect removal and processing speed.

Accuracy in identifying and ejecting unwanted material is paramount. Both Bühler and Metak employ sophisticated technologies, but they target different operational priorities.

Bühler sets the industry benchmark for precision. Its machines utilize advanced multi-spectral cameras and proprietary InGaAs (Indium Gallium Arsenide) technology. This allows the sorter to "see" beyond the visible light spectrum. As a result, a Bühler sorter excels at identifying:

Subtle color and shade variations in beans.

Diseased or damaged spots that are nearly invisible to the human eye.

Foreign materials with similar colors to garbanzo beans, such as stones, glass, and unhulled seeds.

A high-end model like the Bühler Sortex Z+ is capable of achieving purity levels of up to 99.97% across various seed products. The machine includes specific calibration programs for chickpeas, ensuring top-tier sorting results.

Metak, on the other hand, provides a powerful balance of performance and value. Its full-color RGB cameras and intelligent shape-recognition algorithms are highly effective for most sorting tasks. A Metak garbanzo beans sorting machine reliably removes common defects that impact grade and safety.

Note: Metak's technology is engineered to eliminate the most prevalent issues facing garbanzo processors, including discolored beans, broken pieces, insects, and common foreign materials like sticks and pods. For many businesses, this level of accuracy meets or exceeds market requirements without the premium investment.

| Feature | Bühler | Metak |

|---|---|---|

| Purity Potential | Industry-leading (up to 99.97%) | High (typically 99.5%+) |

| Defect Scope | Detects subtle and invisible defects | Focuses on common and obvious defects |

| Ideal Application | Export-grade, food safety compliance | Standard processing, improving local grade |

Throughput, measured in tons per hour, determines how much product a facility can process. This metric is crucial for aligning sorting capacity with overall production goals.

Bühler machines are engineered for maximum uptime in large-scale, 24/7 industrial environments. They are built to handle immense volumes without sacrificing accuracy. Their high-speed ejectors fire with microsecond precision, ensuring that good beans are not accidentally removed along with defects, even at the highest processing speeds. This efficiency minimizes waste and maximizes the yield of saleable product from every batch.

Metak offers excellent flexibility with a range of models designed to scale with a business's needs.

Scalable Models: Metak provides sorters with varying chute counts, allowing businesses to choose a machine that matches their current volume.

Efficient Processing: The machines deliver consistent throughput for small to medium-sized operations, preventing bottlenecks in the production line.

Balanced Speed: Metak optimizes its sorters to provide a strong balance between processing speed and sorting accuracy, ensuring a cost-effective and reliable performance.

Ultimately, Bühler is designed for processors who measure output in hundreds of tons per day. Metak provides an adaptable and powerful solution for businesses that need reliable performance for growing operations.

The hardware and software within a sorter determine its intelligence and operational efficiency. Advanced technology not only improves accuracy but also simplifies daily operations for plant staff. Here, we examine the core technologies that power Bühler and Metak machines.

The "eyes" of a garbanzo beans sorting machine are its sensors. Bühler leads with multi-spectral cameras and InGaAs sensors. This technology allows the machine to detect defects beyond the visible spectrum, identifying issues like rot or foreign materials that look identical to good beans. This capability is crucial for meeting the highest export and food safety standards.

Metak utilizes high-resolution, full-color RGB cameras. These sensors are highly effective at spotting common defects based on color, size, and shape. For most processors, this technology provides excellent sorting results, reliably removing discolored beans, splits, and common field debris to produce a high-quality commercial grade product.

A powerful machine requires an intuitive interface. Bühler’s SORTEX ProSortX software is designed for expert control and deep analysis. Key features include:

TrueColor™ User Interface: This shows operators real-time captures of defects, allowing for immediate parameter adjustments.

EasySim™ Simulation: Operators can test new settings on captured images without affecting the live product flow, minimizing downtime and waste.

Bühler recognized that complex interfaces increased training needs. The company initially required five days of operator training. It has since focused on creating more intuitive designs to reduce support costs and simplify machine setup.

Metak’s software prioritizes simplicity and accessibility. The user-friendly interface is designed for quick adoption and efficient operation. It offers:

A newly-optimized operating interface for straightforward navigation.

A "one-button auto" function that simplifies setup for different batches.

A "project back-up" feature to instantly restore original parameters if an operator makes a mistake.

A financial analysis reveals two distinct investment strategies. The decision between Bühler and Metak extends beyond the initial price tag. It involves a careful evaluation of long-term operational costs and the return on investment (ROI) each machine delivers.

The upfront capital required to acquire and install a sorter is a primary consideration for any business.

Bühler represents a significant capital investment. The company positions its machines as premium, enterprise-grade solutions. The higher price reflects its cutting-edge sensor technology, robust engineering, and the brand's global reputation for quality. The purchase price often includes a comprehensive package. This package covers professional installation, on-site calibration, and initial operator training, ensuring the machine performs optimally from day one. This approach is tailored for large corporations where performance and reliability justify a substantial upfront cost.

Metak offers a more accessible entry point into optical sorting. The company focuses on providing a strong price-to-performance ratio. This makes a high-quality garbanzo beans sorting machine attainable for small to medium-sized enterprises (SMEs) and growing businesses. Metak's lower initial cost allows processors to adopt modern sorting technology without the heavy capital burden associated with premium brands. Installation is typically straightforward, minimizing associated setup expenses.

The choice reflects a core business strategy. Bühler is an investment in top-tier technology for maximum long-term asset value. Metak is an investment in immediate capability and faster ROI for businesses scaling their operations.

Long-term profitability depends heavily on ongoing operational expenditures (OpEx). These costs include energy, spare parts, and maintenance.

Bühler machines are engineered for exceptional long-term efficiency. Their high-speed, precise ejectors reduce compressed air consumption, a major operational cost. Furthermore, the extreme accuracy minimizes the rejection of good beans, directly increasing saleable yield and revenue. While genuine Bühler spare parts carry a premium price, the machine's durable construction often leads to less frequent replacement needs. The overall design prioritizes a low total cost of ownership over a 10-20 year lifespan.

Metak designs its machines for cost-effective and predictable maintenance. The company ensures that spare parts are both affordable and readily available. This strategy minimizes downtime and keeps repair budgets manageable. The energy consumption is optimized for standard production environments, providing a reliable balance between performance and daily running costs. For businesses where controlling monthly expenses is critical, Metak presents a compelling financial case.

| Cost Factor | Bühler | Metak |

|---|---|---|

| Energy Use | Highly efficient; lower air consumption | Optimized for standard operational needs |

| Spare Parts Cost | Premium pricing for genuine parts | Affordable and readily available |

| Yield Impact | Maximizes yield with high precision | Strong performance with minimal good loss |

| Service Fees | Higher rates for specialized technicians | Cost-effective local support options |

Ultimately, the financial model for a Bühler sorter favors large-scale processors who can leverage its efficiency to generate significant returns over many years. The model for a Metak sorter benefits businesses needing to manage operational costs closely while achieving a high-quality sort.

An optical sorter is a long-term asset. Its reliability and the support behind it are critical for maintaining production continuity and protecting the investment. A machine's durability determines its operational lifespan, while responsive support minimizes costly downtime.

Here’s how Bühler and Metak compare in these crucial areas.

A machine's construction quality directly impacts its longevity and performance under demanding industrial conditions.

Bühler engineers its machines for maximum durability using a "Designed for Reliability" (DfR) methodology. This process identifies and eliminates potential weak points. The company constructs its sorters to high-quality standards, ensuring stable performance for many years. Key models often feature stainless steel construction, which provides excellent resistance to corrosion and wear in food processing environments. This robust build quality means a Bühler machine can operate reliably for 5-10 years, and often much longer.

| Machine Component | Primary Material | Grade |

|---|---|---|

| Bühler DSC Sortex | Stainless Steel | SS 304 |

| Bühler Sorting Machine | Stainless Steel | N/A |

Metak focuses on building durable and practical machines for its target market. The company uses quality materials and proven engineering to create a reliable garbanzo beans sorting machine that withstands daily operational stress. While perhaps not built to the same extreme industrial specifications as Bühler, Metak sorters offer excellent durability for small to medium-sized operations. Their design prioritizes ease of maintenance and component accessibility, ensuring a long and productive service life.

Effective support ensures that any operational issues are resolved quickly, keeping production lines running.

Bühler provides a comprehensive global support network. Its service offerings are extensive, designed to maximize uptime and machine lifecycle.

24/7 Hotline: Immediate access to expert assistance.

Global Parts Network: Ensures the availability of original spare parts, which is essential for maintaining the machine's warranty and performance.

Expert Services: On-site support for maintenance, process optimization, and upgrades.

Bühler's extensive support infrastructure is a key value proposition for large-scale producers who cannot afford significant downtime.

Metak offers strong, accessible customer support tailored to its client base. The company emphasizes providing readily available and affordable spare parts, which reduces the total cost of ownership. Their support teams are responsive and focused on providing practical solutions to keep machines operational. For many businesses, Metak's combination of reliable local support and cost-effective parts provides excellent value and peace of mind.

The choice between Bühler and Metak depends on your operational scale and priorities. Bühler excels in high-precision, large-scale environments. Metak provides optimal value for growing businesses.

Final Decision Guide 📝

Choose Bühler if your top priority is achieving the highest purity standards in a 24/7 operation.

Choose Metak if you need a reliable, budget-friendly machine with strong performance.

Metak offers a strong price-to-performance ratio. It provides an accessible entry point for new businesses, allowing for a faster return on investment and scalable growth.

Bühler utilizes advanced multi-spectral and InGaAs sensors. This technology detects subtle defects beyond the visible spectrum, achieving superior purity levels required for export-grade products.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Uneven and overlapped product detection, thin & lo...

Recommedation: Rice, wheat, corn, grain, pulses, s...

High cost performance, compact design, high sensit...

Recommedation: Small particle, flat products such...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Pistachios are a premium, high-value commodity. Co...

MoreAdvanced nut sorting machine technology combines H...

MoreFor processors, the challenge is evolving. It is n...

MoreX-ray inspection machines have become indispensabl...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Production SupervisorThis garbanzo bean sorting machine has revolutionized our production line. The accuracy and speed are remarkable, reducing waste by 40% compared to our previous manual sorting process. Highly recommended for any legume processing facility.

Sarah Chen

Quality Control ManagerExcellent machine for garbanzo bean sorting. The optical sorting technology effectively removes defective beans and foreign materials. Minor maintenance required, but overall performance exceeds expectations. Great value for money.

David Thompson

Plant ManagerOutstanding investment! This sorting machine handles 2 tons of garbanzo beans per hour with 99% accuracy. The user-friendly interface and minimal downtime have significantly boosted our productivity. Customer support is also very responsive.

Jennifer Williams

Operations DirectorAfter 3 months of continuous operation, this garbanzo bean sorter continues to impress. The machine's consistency in quality output has helped us maintain premium product standards. The energy efficiency is an added bonus to our sustainability goals.