Revolutionizing Quality Control with Advanced Hazelnuts Sorting Machines

Advanced nut sorting machine technology combines H...

More

An automated corn sorting system presents a significant opportunity for operational enhancement. It promises substantial gains in efficiency and product quality. However, these benefits come with high initial costs and demanding operational requirements. The decision to invest hinges on a careful balance of these pros and cons against an operation's specific scale, quality standards, and financial capacity.

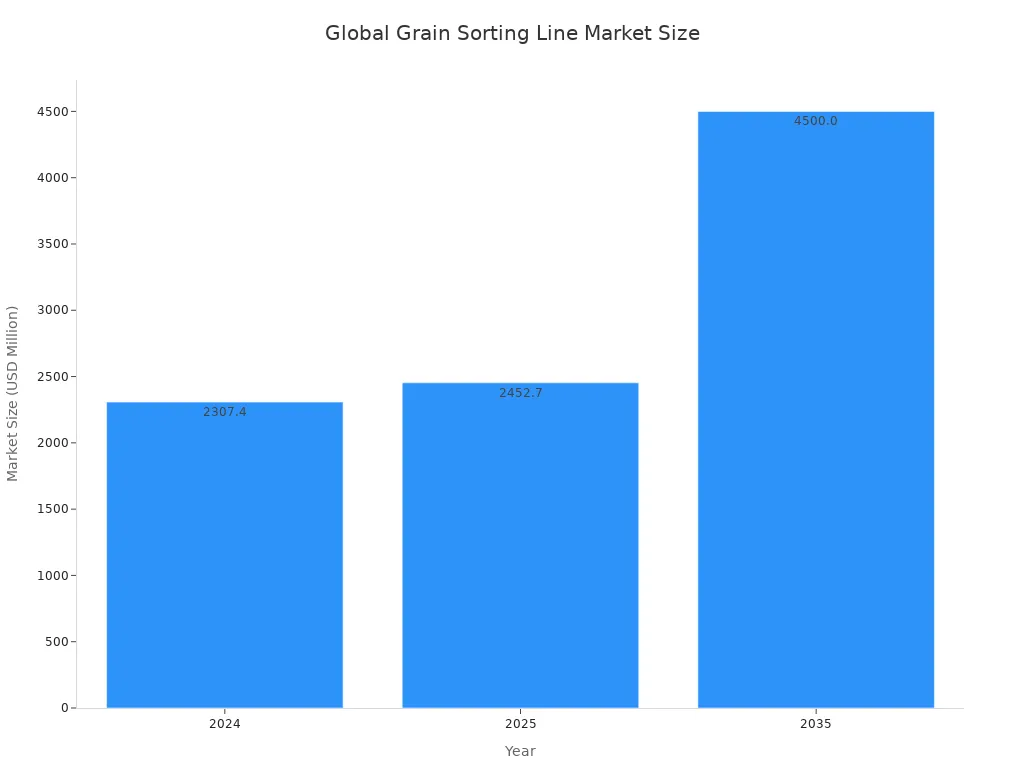

💡 Market Insight: The global grain sorting market is expanding rapidly, indicating a strong industry trend toward automation. Projections show significant growth in the coming years.

The global grain sorting line market size is projected to grow substantially, reflecting this trend.

Choosing the right corn sorting machine requires a thorough evaluation of these competing factors.

Automating the corn sorting process offers transformative benefits for agricultural operations. Processors can achieve significant improvements in accuracy, speed, and safety. These advantages translate directly into higher profitability and a stronger market position.

Human sorters are prone to fatigue and inconsistency. An automated corn sorting machine provides a level of precision that manual labor cannot replicate. These systems operate with unwavering accuracy around the clock.

Advanced sorters use a combination of powerful technologies.

Near-Infrared (NIR) Spectroscopy: This technology analyzes the molecular composition of each kernel. It detects invisible defects like mold or internal damage that the human eye would miss.

Machine Vision: High-definition cameras capture detailed images of corn kernels. Machine vision technology then analyzes parameters like color, saturation, and size to identify imperfections or predict seed vitality with high accuracy.

AI-Driven Analysis: Deep learning algorithms process the data from NIR and vision sensors. The AI continuously learns and optimizes sorting parameters, improving its performance over time without operator intervention.

This technological synergy results in exceptional defect removal. Studies show that automated systems in the agricultural sector achieve defect detection rates of over 90%. Some advanced optical sorters reach a defect removal accuracy of up to 99%, leading industrial processors to experience a 37% reduction in final product rejection rates.

Speed is a critical factor in large-scale corn processing. Automation provides a massive boost to operational throughput. A modern corn sorting machine can process materials at rates far exceeding any manual team.

| Feature | Automated Sorting | Manual Sorting |

|---|---|---|

| Processing Speed | 1 to 20 tons per hour | Limited by human speed and endurance |

| Operational Hours | Can run 24/7 without breaks | Requires shifts, breaks, and downtime |

| Consistency | Maintains constant speed and accuracy | Performance varies with fatigue and skill |

Specialized seed processing lines can handle volumes between 800 and 1,000 bushels per hour. This high-speed capability allows facilities to process more corn in less time, increasing overall productivity and enabling faster delivery to market. The system's ability to work continuously ensures a steady, predictable output.

A primary advantage of automation is the ability to remove harmful contaminants and defective kernels, significantly enhancing final product quality and safety. Automated sorters are particularly effective at identifying kernels affected by mycotoxins, such as aflatoxin and fumonisin, which pose serious health risks.

💡 How It Works: Sorters identify mycotoxin contamination by detecting specific visual cues. Aflatoxin-affected kernels, for example, emit a distinct bright green-yellow fluorescence (BGYF) under UV light.

The system uses this principle for precise removal:

Specialized cameras detect the unique BGYF signature of contaminated kernels.

Computer vision algorithms, sometimes aided by augmented reality overlays for operators, confirm the presence of mold, black spots, or broken pieces associated with contamination.

High-frequency pneumatic ejectors then physically remove the identified bad kernels from the product stream with surgical precision.

This risk-based sorting method is far more effective than random sampling. Classification models based on these visual characteristics have achieved significant reductions in mycotoxin levels, with one study showing a mean aflatoxin reduction of 31 ppb.

The high initial investment in a corn sorting machine is offset by substantial long-term savings in labor costs. Manual sorting is labor-intensive, requiring significant expenditure on wages, benefits, recruitment, and training. Automation drastically reduces the number of employees needed on the sorting line.

This reduction in labor dependency offers several key benefits. It mitigates challenges related to labor shortages and high turnover rates. It also minimizes the potential for human error, which can lead to inconsistent quality and product loss. While skilled technicians are needed to operate and maintain the equipment, the overall reliance on a large manual workforce diminishes, leading to a more stable and predictable operational cost structure over time.

Modern automated sorters are not just processing machines; they are powerful data collection tools. They generate a wealth of real-time information that can be used to drive intelligent business decisions and optimize the entire production chain.

These systems capture a wide range of data points, including:

Defect rates and types (e.g., broken, discolored, moldy)

Kernel properties like size, shape, and color distribution

Real-time product flow and throughput statistics

Kernel loss conditions during processing

Processors can leverage this data analytics to make impactful improvements. For example, by analyzing defect data, a company can trace quality issues back to specific harvesting equipment or field practices, allowing them to advise growers on adjustments. This data also enables predictive maintenance, as the system can identify when upstream equipment, like a cracker, is damaging good kernels. Ultimately, these insights help optimize raw material utilization, increase yields, and eliminate recurring quality problems.

While the benefits of automation are compelling, a transition to an automated system introduces significant challenges and costs. Business owners must carefully weigh these disadvantages before committing to such a large-scale investment. A failure to do so can lead to financial strain and operational disruption rather than the desired efficiency gains.

The most immediate and significant barrier to adopting automation is the high upfront cost. An industrial-grade optical corn sorting machine represents a major capital expenditure. Depending on capacity, features, and technological sophistication, the price for a new system can vary widely. For example, a larger capacity color sorter can fall into a price range of $10,000 to $100,000. This cost does not include installation, integration with existing equipment, or facility modifications, which can add thousands more to the initial bill. For small and medium-sized processors, this level of investment can be prohibitive, making it a non-starter without substantial financing or grants.

The expenses associated with a corn sorting machine do not end after the initial purchase. Operations must budget for a range of continuous costs to keep the system running effectively.

Preventative Maintenance: Regular servicing is essential to prevent breakdowns. This often involves service contracts with the manufacturer, which can be costly.

Spare Parts: Components like cameras, ejectors, and light sources have a finite lifespan and require replacement. Keeping a stock of critical spare parts is necessary to minimize downtime.

Software and Licensing: Advanced systems run on proprietary software that may require annual licensing fees or paid updates to access new features and security patches.

Energy Consumption: These powerful machines consume a significant amount of electricity, adding to the facility's daily operational expenses.

These recurring costs contribute to the Total Cost of Ownership (TCO), a figure that is often much higher than the initial purchase price alone.

Automated systems replace manual laborers with a smaller, more specialized technical workforce. Employees must have the expertise to operate, calibrate, and maintain the sophisticated equipment. This requirement creates a new set of challenges related to staffing and training.

💡 Training Insight: Generic operational knowledge is insufficient. Staff require vendor-specific training to manage these complex systems effectively.

Companies must invest in comprehensive training programs, which can include:

Basic Operations: Short courses, like the half-hour Sorter Operations program from 360training, cover fundamental concepts of induction, scanning, and sortation.

Advanced Maintenance: In-depth, instructor-led training from providers like Dematic University focuses on specific mechanical and control systems to reduce maintenance costs and improve diagnostics.

Custom Solutions: Many vendors offer custom training programs tailored to a customer's specific equipment and operational needs, covering everything from daily troubleshooting to full system recovery scenarios.

This need for skilled technicians can be a hurdle in areas with a limited talent pool, forcing companies to invest heavily in recruitment and continuous education.

An automated line is highly efficient when running, but it is also vulnerable to complete shutdowns. Unlike a manual sorting line where one person's absence has a minor impact, a malfunction in the central sorting machine can bring the entire process to a halt. A mechanical failure, software glitch, or sensor issue can stop production for hours or even days.

A prominent frozen foods company experienced this firsthand. Its automated system for corn sorting had a flawed vision system that led to missed picks and damaged equipment. The machine failed to meet its target of 60 picks per minute, achieving only about 40. This underperformance caused production halts and, according to Mike Welborn of Oxipital AI, prevented the company from realizing its expected return on investment in terms of yield, quality, and cost. This example highlights how a single point of failure can cripple productivity and negate the financial benefits of automation.

Automated sorting systems are designed for high-volume, continuous processing of a uniform product. They excel in environments where they can be calibrated once and run for extended periods. However, they offer limited flexibility for operations that handle small or highly diverse batches of corn.

| Scenario | Automated Sorter Suitability | Manual Sorter Suitability |

|---|---|---|

| Large, uniform batch | ✅ Excellent | ❌ Inefficient |

| Multiple small, diverse batches | ❌ Inefficient | ✅ Flexible |

| Switching between corn varieties | Requires recalibration time | Minimal adjustment needed |

Each time a new corn variety with different size, shape, or color characteristics is introduced, the machine requires recalibration. This process involves adjusting sensor sensitivity, software parameters, and ejector timing. The setup and changeover time can be significant, reducing the overall efficiency for processors who need to switch between different products frequently. For these businesses, the downtime associated with recalibration may outweigh the speed benefits of automation.

The decision boils down to a trade-off: significant upfront investment versus long-term gains in efficiency and profitability. For large-scale operations, the benefits typically justify the cost. Smaller operations must conduct a detailed cost-benefit analysis.

The Robot Assisted Farming Solutions Financial Model offers comprehensive financial projections.

General templates from Template.net can be adapted for specific projects.

Before deciding, carefully evaluate processing volume, quality targets, and capital resources.

The ROI period varies based on operational scale, labor savings, and quality improvements. High-volume processors typically experience a faster return on their initial investment.

Yes, many modern sorters offer versatility. Operators can recalibrate the machines for other grains. Frequent changeovers, however, may decrease the system's overall efficiency.

Optical sorters use cameras to identify surface defects like discoloration. NIR sorters analyze molecular structure, detecting internal issues such as mold or moisture invisible to the eye.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Glass-in-glass / Metal-in-metal inspection, small ...

Recommedation: Small particle, flat products such...

Recommedation: Aquatic products, pet food, candy, ...

Both fat analysis and contaminant inspection (bone...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Advanced nut sorting machine technology combines H...

MorePistachios are a premium, high-value commodity. Co...

MoreBone fragments are the poultry industry’s most per...

MoreWhy do IP65/IP67 fail in food plants? Discover the...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Robert Johnson

Farm ManagerThis corn sorting machine has revolutionized our harvesting process. The accuracy in separating quality kernels is remarkable, and it has significantly reduced our manual labor costs. Highly recommended for modern farms!

Emily Chen

Food Processing EngineerAs a food processing professional, I'm impressed with this machine's efficiency. It handles large volumes with consistent precision, though the initial setup required some technical adjustments. Great value for industrial use.

Michael Rodriguez

Agricultural TechnicianThe automated sorting capability exceeded our expectations. It identifies and removes defective corn with 99% accuracy, and the user-friendly interface makes operation simple even for new staff. Outstanding investment!

Sarah Williams

Quality Control SupervisorThis machine has dramatically improved our product quality standards. The optical sorting technology is impressive, though we wish the maintenance intervals were longer. Overall, a reliable workhorse for our facility.