RaymanTech Whole-Chain Solution: A Deep Dive

Food safety and quality control demands have evolv...

More

AI-powered optical sorters are achieving unprecedented precision. They identify and remove defects from rotini pasta, revolutionizing production standards. This advanced rotini optical sorter delivers enhanced defect detection. The technology also boosts operational efficiency. It ensures a superior final product quality for consumers, setting a new benchmark in food processing.

Artificial intelligence achieves its remarkable precision through a combination of advanced training, powerful hardware, and sophisticated software. The system learns to identify defects with an accuracy that surpasses human capabilities, transforming the standards of quality control.

At the core of this technology is a process called deep learning. Developers train the AI model using a massive dataset containing thousands of images of rotini pasta. These images showcase everything from perfectly formed pieces to those with various defects. The AI's neural network analyzes these examples, learning to distinguish between acceptable and unacceptable pasta. Through this extensive training, the system builds an intricate understanding of what constitutes a high-quality product.

The AI's intelligence works in tandem with high-resolution cameras that act as its eyes. These cameras capture detailed images of each piece of pasta from multiple angles. Sophisticated computer vision algorithms then analyze these images instantly. The system is trained to detect even the smallest imperfections that are often invisible to the human eye.

This technology excels at identifying a wide range of defects, including:

Black spots or discoloration

Cracks and breakage

Misshapen pieces

Foreign material

Unlike traditional batch sampling, an AI-powered rotini optical sorter inspects every single piece of pasta as it moves along the production line. This real-time analysis provides 100% inspection coverage, eliminating the risk of defective products slipping through. The immediate feedback allows for instant removal of flawed items, ensuring a consistently superior final product. The difference between real-time AI processing and older methods is significant.

| Feature | Real-Time AI Processing | Traditional Batch Processing |

|---|---|---|

| Processing Speed | Immediate analysis as pasta moves | Slower, processes data in intervals |

| Data Arrival | Each piece is processed instantly | Data is collected and processed later |

| Latency | Very low latency for rapid action | Higher latency, causing delays |

Integrating AI into pasta production delivers far more than just improved sorting. It creates a ripple effect of benefits that enhance quality, boost productivity, and empower teams. This technology provides a clear return on investment by transforming key areas of the manufacturing process.

The primary benefit of an AI-powered sorter is a dramatic improvement in the final product. The system’s precision ensures that only rotini meeting the highest standards reach the consumer. It consistently identifies and removes pieces with subtle discoloration, hairline cracks, and minor shape deformities. This meticulous inspection guarantees a uniform, premium-quality product in every package, strengthening brand reputation and consumer trust. By eliminating defects that human inspectors might miss, manufacturers can deliver a product that looks as good as it tastes.

Automation is a cornerstone of modern manufacturing, and AI-powered sorting takes it to the next level. Computer vision reviews product quality at speeds unmatched by human crews. AI systems operate continuously without breaks or fatigue, boosting throughput and shortening production lead times. This significantly reduces the time and costs associated with manual inspection. By delegating repetitive sorting tasks to automation, companies can reassign skilled personnel to focus on more strategic responsibilities like quality assurance management and process optimization. This shift not only cuts labor costs but also elevates the roles of production staff.

A common challenge in traditional sorting is the high rate of false rejects, where perfectly good products are mistakenly discarded along with defects. An AI-powered rotini optical sorter addresses this issue with exceptional accuracy. Advanced systems use a narrow nozzle pitch, some as small as 6mm, to eject only the targeted defective piece. This pinpoint precision minimizes the loss of acceptable product, directly increasing yield.

The impact of AI on sorting accuracy is well-documented across various industries, setting a clear benchmark for performance.

| Industry | Traditional Accuracy | AI-Powered Accuracy |

|---|---|---|

| Steel Production | ~70% | >98% |

| General Visual Inspection | N/A | >98% |

| Pharmaceutical | N/A | >97% |

This leap in precision means more sellable product from the same amount of raw material, reducing food waste and maximizing profitability.

Despite its advanced capabilities, a modern rotini optical sorter is designed for ease of use. Manufacturers equip these systems with intuitive, user-friendly interfaces that feature simple sliders and visual configurations. This design drastically reduces the learning curve for new operators. Staff can quickly review performance data, make minor adjustments, and let the AI handle the complex analysis, ensuring accurate calibration and consistent operation.

Beyond simplifying tasks, the technology empowers managers with actionable data.

The sorter acts as a powerful data collection point, providing insights that drive smarter business decisions. Well-sorted data enables managers to track performance metrics, monitor trends in real-time, and optimize operations before risks escalate.

By analyzing large datasets from the production line, AI helps managers with:

Resource Allocation: Predictive analytics forecast potential bottlenecks and suggest preemptive measures to keep the line running smoothly.

Inventory Management: AI-driven analytics optimize stock levels by analyzing sales trends and seasonality, reducing carrying costs and preventing stockouts.

Strategic Planning: Access to real-time data on defect rates and raw material quality allows for more accurate forecasting and better risk management.

This data-driven approach transforms the sorter from a simple machine into a strategic asset for continuous improvement.

The impact of AI on pasta production extends far beyond current capabilities. This technology is charting a course for a smarter, more adaptable, and continuously improving future in food processing. It represents a foundational shift that will redefine industry standards for years to come.

AI-powered sorting is establishing a new global benchmark for quality and safety. Automation trends are critical for meeting strict regulatory requirements in international trade. AI-integrated systems improve traceability and quality assurance, aligning with global shifts toward higher food safety and sustainability standards. This technological advancement sets a new expectation for efficiency and safety, giving manufacturers a crucial competitive edge in a global market with tightening regulations.

The intelligence driving the rotini optical sorter is highly adaptable. The same core technology can be trained to handle other complex products. Pre-trained AI models already exist that can identify numerous pasta varieties.

Fusilli

Farfalle

Penne

Spaghetti

This versatility extends beyond pasta. AI-driven machine vision also sorts other foods with irregular shapes, such as potatoes, fruits, and vegetables. It identifies size, grade, and defects, ensuring that only the best products move forward.

Perhaps the most powerful aspect of this technology is its ability to evolve. AI systems learn from the data they process every day.

This continuous self-improvement cycle means the sorter becomes progressively more intelligent and accurate over time. It can identify new defect patterns and adapt to variations in raw materials without needing constant manual intervention.

This evolution ensures that the sorting process remains at the cutting edge, constantly refining its performance and delivering long-term value.

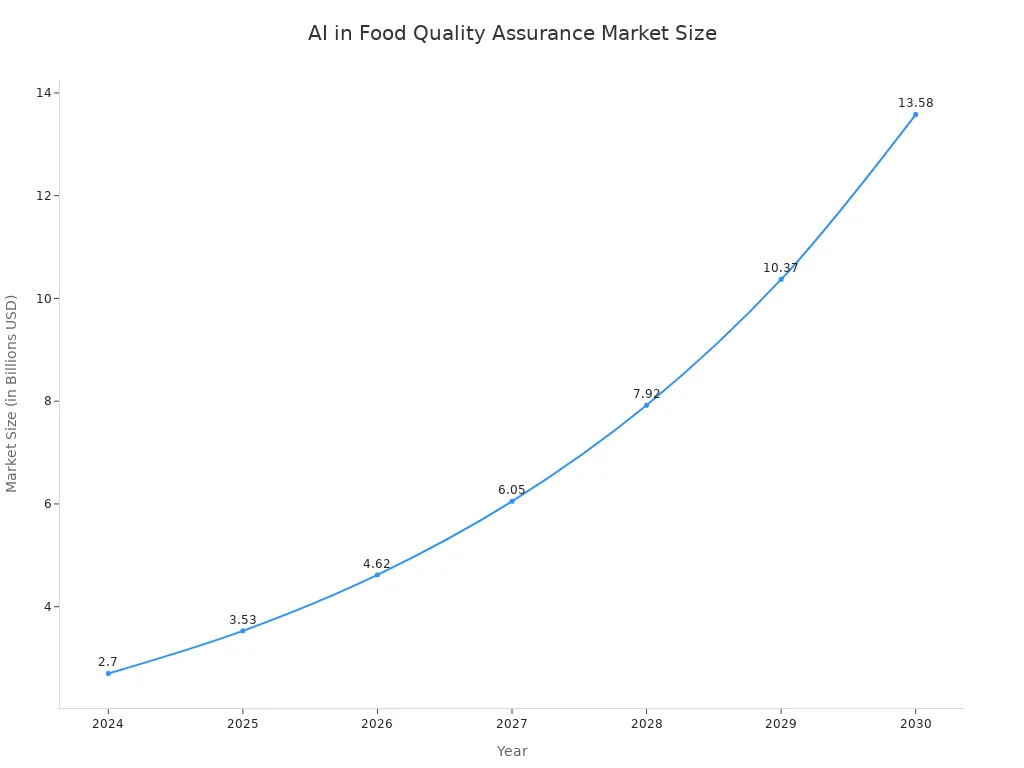

AI-driven sorting technology directly overcomes the unique challenges of rotini pasta. It delivers measurable improvements in precision, quality, and efficiency. This technology marks a transformative shift in food processing, setting a new standard for quality assurance. The market for AI in food quality is projected to grow significantly, reflecting this trend.

Producers are invited to explore how this groundbreaking sorting solution can elevate their production lines.

Yes. The system's deep learning models adapt to other complex shapes. Manufacturers train the AI to accurately sort fusilli, penne, and farfalle with high precision.

Integration is straightforward. These sorters feature a compact design and user-friendly software. This allows for seamless installation with minimal disruption to current operations.

AI sorters require minimal maintenance. Standard procedures include routine cleaning of cameras and hardware checks. The AI software continuously updates itself to improve performance over time.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

UHD X-Ray detector, AI large model, all food indus...

Recommedation: Chili, walnut, peanuts, soybeans, c...

Conventional and unconventional contaminant detect...

Recommedation: Aquatic products, pet food, candy, ...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Food safety and quality control demands have evolv...

MoreRaymanTech, as a leading provider of inspection an...

MoreIn the fast-paced world of food production, ensuri...

MoreBone fragments are the poultry industry’s most per...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Control ManagerThe Rotini optical sorter has revolutionized our pasta production line. Its accuracy in detecting and removing defective products is exceptional, reducing waste by over 30%.

Sarah Chen

Production SupervisorIncredible machine! The Rotini sorter's high-speed processing and color recognition capabilities have significantly improved our product quality while maintaining throughput.

David Thompson

Plant EngineerReliable and efficient optical sorting solution. The easy-to-use interface and minimal maintenance requirements make it a valuable addition to our processing line.

Jennifer Williams

Operations DirectorOutstanding investment! The Rotini optical sorter has consistently delivered superior sorting accuracy, helping us maintain the highest quality standards for our specialty pasta products.