AI + Ultra-HD: The Ultimate AI Optical Sorter for Wet Processed Meat Lines

Optical sorting technology has become indispensabl...

More

Global food waste presents a massive challenge. The economic loss from discarded food now exceeds one trillion U.S. dollars each year. This waste occurs at every stage of the supply chain.

| Stage of Supply Chain | Percentage of Food Waste |

|---|---|

| Upstream (Production, Handling, Storage) | 54% |

| Downstream (Processing, Distribution, Consumption) | 46% |

Food artificial intelligence offers a powerful solution. It gives farmers, distributors, and retailers advanced tools. These tools help them produce, move, and sell food with incredible efficiency, preventing spoilage and surplus across the board.

Farms are the foundation of the food supply chain. AI technologies are transforming them into highly efficient, data-driven operations. This shift begins with precision agriculture and extends to automated harvesting, tackling waste at its source.

Precision agriculture uses technology to make farming more accurate and controlled. Food artificial intelligence analyzes vast amounts of data to optimize crop health and resource use. Drones and sensors gather real-time information from the fields.

AI systems process key data points to make decisions:

Soil moisture and nutrient levels

Plant health indicators

Field temperature and humidity

Meteorological forecasts

This data allows for early and precise interventions. For example, AI-powered computer vision can detect apple scab disease with 95% accuracy. This enables farmers to apply treatments only where needed, preventing crop loss and reducing pesticide use. By optimizing water, fertilizer, and pest control, precision agriculture can increase crop yields by as much as 30%, ensuring more food makes it off the farm.

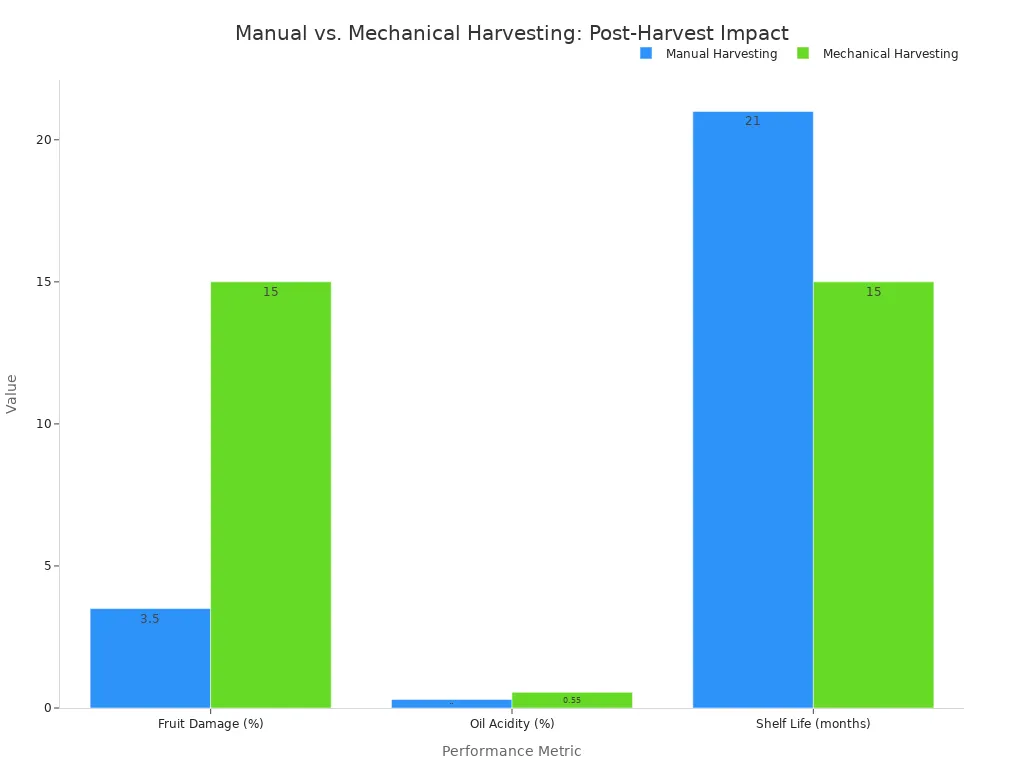

Timing the harvest is critical for preventing spoilage. AI-powered robots now automate this crucial step with incredible precision. These machines use advanced deep learning models and hyperspectral imaging to assess ripeness. They analyze visual cues like color and texture to determine the perfect moment to pick.

Automated systems significantly reduce post-harvest losses, which can reach up to 50% in delicate leafy vegetables. Robotic harvesters from companies like Agrobot and Tortuga AgTech handle produce gently, minimizing the bruising and physical damage common with manual methods. This careful handling extends shelf life and preserves quality.

By harvesting produce at its peak and handling it with care, automation ensures that more high-quality food leaves the field, ready for the journey to consumers.

Once produce leaves the farm, the clock starts ticking. The journey from producer to retailer is a critical phase where significant waste can occur. Food artificial intelligence provides powerful tools to streamline this complex process, ensuring food arrives fresh and in the right quantities.

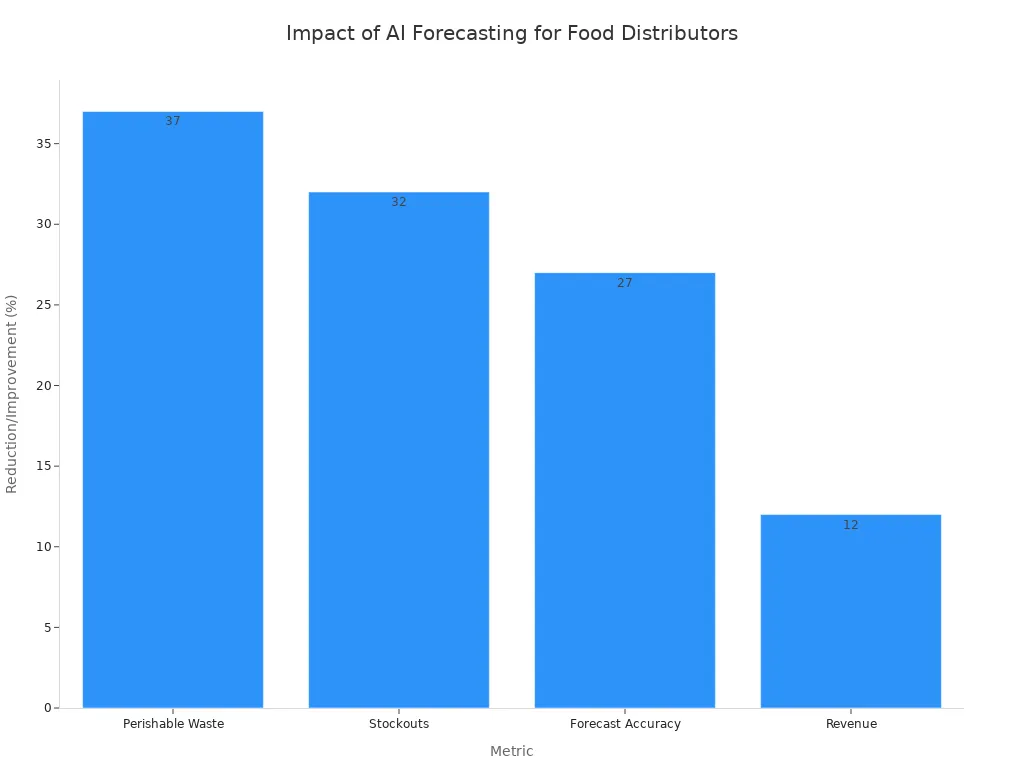

Accurate demand forecasting is essential for preventing overstocking and subsequent spoilage. AI systems vastly outperform traditional methods by analyzing complex data sets in real time. These models process historical sales data alongside external factors like weather patterns, public holidays, and even social media sentiment to predict consumer demand with remarkable precision.

This advanced capability allows distributors and retailers to make smarter purchasing decisions. AI achieves a significant reduction in forecasting errors compared to older, static models.

| Forecasting Horizon | AI Error Reduction vs. Traditional |

|---|---|

| Short-term (< 30 days) | 10-20% |

| Medium-term (30-90 days) | 15-30% |

| Long-term (> 90 days) | 20-40% |

By aligning inventory with actual demand, companies can dramatically cut down on waste. For food distributors, implementing AI has led to impressive results, including major reductions in perishable waste and stockouts.

The physical transportation of food introduces risks of spoilage from delays and improper handling. AI optimizes logistics by creating the most efficient delivery routes. The system calculates the best path by considering traffic conditions, weather forecasts, and delivery time windows.

Note: AI-driven logistics also incorporate IoT (Internet of Things) sensors inside transport vehicles. These sensors monitor crucial conditions like temperature and humidity in real time. If temperatures for perishable goods move outside the safe range (e.g., above 5°C for fresh produce), the system sends an immediate alert. This proactive monitoring ensures that food quality is maintained throughout transit, minimizing spoilage before it even reaches the store.

The retail environment is the final and most consumer-facing stage of the supply chain. Here, food artificial intelligence provides powerful tools that directly influence purchasing behavior and operational efficiency. Retailers use these technologies to minimize waste, optimize stock levels, and maximize the value of every item on their shelves.

Traditional markdowns are often too little, too late. Dynamic pricing uses AI to adjust the price of perishable items in real time. The system analyzes data like inventory levels, sales velocity, and expiration dates to find the optimal discount that encourages a sale before the product spoils. This approach moves items that would otherwise be discarded.

AI-powered pricing models help retailers:

Adjust prices as goods near their expiration date.

Optimize revenue by avoiding steep, last-minute discounts.

Appeal to budget-conscious shoppers, enhancing customer loyalty.

Companies like OrderGrid provide solutions that enable this strategy. Studies show that retailers using this technology see impressive results.

| Metric | Value |

|---|---|

| Food Waste Reduction | 32.8% |

| Revenue Increase | 6.3% |

This smart pricing strategy turns potential losses into revenue while significantly cutting down on waste.

Overstocking is a primary driver of retail food waste. Smart inventory management systems use predictive analytics to align stock levels with actual consumer demand. These systems analyze historical sales data, weather patterns, and local events to forecast needs with high accuracy.

This data-driven precision replaces guesswork. AI automates reordering and recommends optimal safety stock levels for each specific product, preventing the accumulation of excess inventory. For example, Australian wholesaler platform Fresho has helped its clients reduce inventory write-offs by 30-40%. A 2022 pilot study with major retailers found that AI inventory systems reduced food waste by an average of 14.8% per store. By ensuring the right amount of product is on the shelf at the right time, retailers prevent spoilage and improve their bottom line. 🛒

The final links in the food supply chain—restaurants and homes—are major sources of food waste. Artificial intelligence is now entering these spaces, offering smart solutions that help chefs and consumers make better use of their food.

Commercial kitchens operate on thin margins where food waste directly impacts profitability. AI-powered tools provide chefs with the data they need to run a more efficient operation. Systems from companies like LeanPath and Winnow Solutions use AI to analyze discarded food. This analysis identifies patterns at the ingredient level, revealing which menu items are popular and which are not.

This data-driven approach allows kitchens to:

Optimize menu offerings and adjust portion sizes.

Identify peak moments of waste for targeted action.

Generate reports on waste, cost, and environmental impact.

The financial benefits are substantial. Restaurants using these systems report food cost reductions between 2% and 8%. For example, UK-based Bubble CiTea saved £156,000 annually and cut total waste by 44% after implementing an AI reporting system. These tools empower kitchens to align production with actual demand, turning waste into savings.

AI is also making its way into household kitchens. Smart appliances, particularly refrigerators, now include features designed to minimize food spoilage. The market for these devices is growing rapidly, with projections reaching USD 60.20 billion by 2030.

Smart fridges use internal cameras and image recognition to track inventory. They monitor expiration dates and send alerts for items nearing their end of life. Some advanced models, like the Samsung Bespoke Flex Refrigerator, create flexible temperature zones to keep different foods fresh longer. The AI can even suggest recipes based on the ingredients you have on hand, helping you use up food before it goes bad. These innovations give consumers powerful tools to reduce waste in their own homes, one smart meal at a time. 🏠

Food artificial intelligence offers precise, data-driven solutions for every stage of the food system. It provides the tools to build a more sustainable and efficient supply chain. Experts believe the goal of halving food waste is achievable with greater action.

“It demonstrates that the national goal to cut food waste in half by 2030 may, in fact, be possible, but we would need dramatically more action across all food-system sectors for that to happen.” — Dana Gunders, ReFED

Embracing these technologies is critical. Future innovations will continue to drive systemic changes, from optimizing land use to discovering novel protein sources. AI is the essential tool for making a significant dent in global food waste. 🌎

No, AI solutions are becoming more accessible. Many companies now offer scalable platforms and subscription-based services. These models allow small farms, independent restaurants, and local grocers to adopt waste-reduction technologies without a massive upfront investment. This democratization helps the entire food system benefit.

AI enhances food safety through constant monitoring. IoT sensors track temperature and humidity during transport, preventing spoilage. Computer vision systems can also detect contaminants or imperfections on production lines with greater accuracy than the human eye, ensuring unsafe products never reach consumers.

The primary challenges include the initial cost of implementation and the need for high-quality data. Many businesses lack the digital infrastructure to collect the data AI systems require. Overcoming these hurdles is key to widespread adoption and maximizing AI's impact on waste reduction.

Yes, predictive analytics can help. AI models analyze data from public health reports, social media, and supply chain records. They identify patterns that may signal an emerging outbreak.

This early warning system allows authorities and companies to take preventative action, protecting public health and preventing large-scale food recalls.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Recommedation: Frozen vegetables such as green be...

Recommedation: Chili, walnut, peanuts, soybeans, c...

UHD X-Ray detector, AI large model, all food indus...

Recommedation: Small particle, flat products such...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Optical sorting technology has become indispensabl...

MoreIn the fast-paced world of food production, ensuri...

MoreIn today’s highly competitive meat processing indu...

MoreOur AI X-ray Inspection System, tailored for high ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Restaurant ManagerThis food AI system has revolutionized our inventory management and menu planning. The predictive analytics reduced our food waste by 30% in just two months!

Sarah Chen

Food ScientistThe AI-powered flavor profiling tool has accelerated our product development process significantly. While there's a learning curve, the results are impressive and data-driven.

David Thompson

Supply Chain CoordinatorImplementation was seamless and the AI-driven quality control has improved our product consistency dramatically. Customer complaints about quality variations have dropped by 45%.

Jennifer Walsh

Executive ChefThe recipe optimization AI suggests brilliant ingredient substitutions that maintain flavor while reducing costs. It's like having a creative partner that never sleeps!