The Ultimate Guide to Ready Meals X-Ray Inspection: Ensuring Safety and Quality in Every Tray

In the fast-paced modern food industry, the demand for convenience has propelled the ready-to-eat market to unprecedented heights. However, with variety comes complexity. From multi-component trays to various packaging materials like foil and plastic, ensuring food safety is a monumental task. This is where a commercial Ready Meals x-ray machine becomes an indispensable asset for any production line.

As a leading Ready Meals X-ray inspection machine manufacturer, we understand that a single contaminated product can lead to costly recalls and irreversible brand damage. In this guide, we explore how advanced Ready Meals x-ray machine technology safeguards your products and why it is the gold standard for modern food processing.

Why Invest in a Ready Meals X-Ray Inspection Machine?

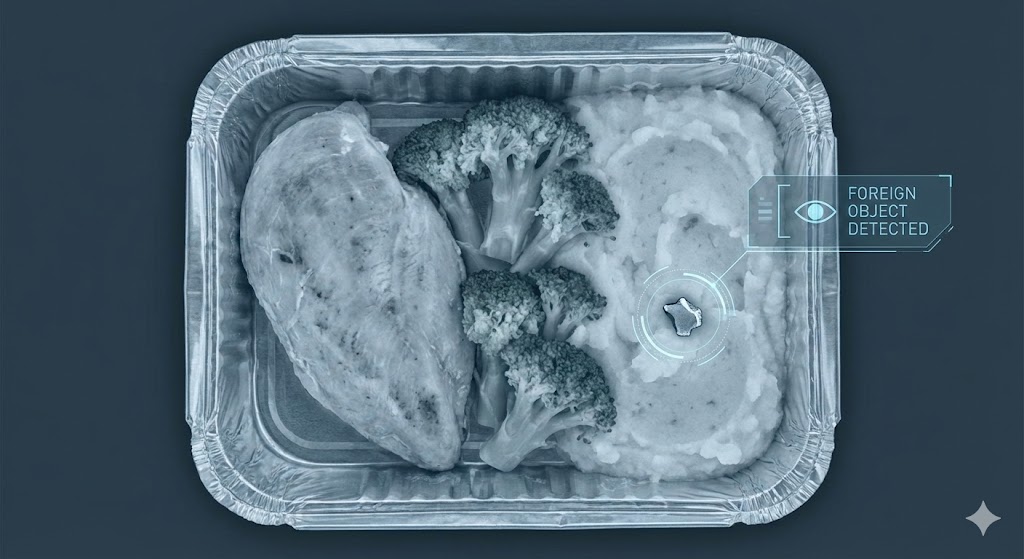

Unlike traditional metal detectors, a Ready Meals x-ray machine goes beyond just finding ferrous and non-ferrous metals. It utilizes density-based imaging to detect a wide array of foreign objects including glass, stone, calcified bone, and high-density plastics—even if the product is packaged in aluminum foil or metallic trays.

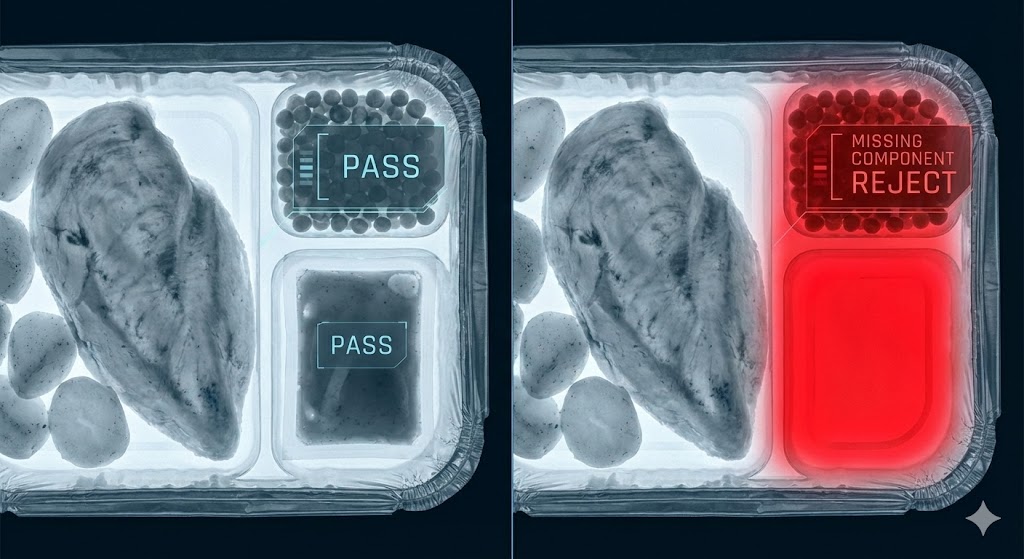

Beyond safety, these systems serve as a comprehensive quality control hub, performing:

● Missing Component Detection: Ensuring every tray has the correct number of items (e.g., meat, veg, and sauce).

● Fill Level Monitoring: Verifying that containers are neither underfilled nor overfilled.

● Seal Integrity Checks: Detecting food trapped in seals that could lead to spoilage.

● Mass Estimation: Providing weight checks for each zone of a multi-compartment tray.

Key Inspection Focus by Category

To maintain the highest standards, it is essential to understand the specific risks associated with different types of ready-to-eat products. The following table summarizes the core categories and their specific inspection priorities:

Ready Meals Quality & Contaminant Detection Matrix

Category | Examples | Inspection Priorities |

Frozen Meals | TV dinners, frozen pasta (lasagna, mac & cheese), frozen pizza. | Contaminants: Metal (spare parts, weld slag, drill chips), stone, hard plastic, ceramic, or glass.

Missing Components: Inserts and dividers. |

Microwaveable Meals | Entrees (chicken pot pie, beef stew, fried rice), microwaveable rice and noodles. | Contaminants: Metal, stone, hard plastic, ceramic, or glass.

Missing Components: Sauce, dip, or gravy; utensils. |

Canned Ready Meals | Canned soups and stews, canned pasta, canned meat meals (beef stew, tuna casserole). | Foreign Objects: Bone fragments (for meat meals).

Contaminants: Metal, stone, hard plastic, ceramic, or glass.

Integrity: Non-standard can shapes (dents or deformations). |

Canned Fish and Seafood | Canned tuna, salmon, sardines; canned crab meat, clams. | Foreign Objects: Fish bone fragments.

Contaminants: Metal, stone, hard plastic, ceramic, or glass.

Integrity: Non-standard can shapes (dents or deformations). |

Ready-to-Serve Salads | Pre-packaged salad kits and meal kits (e.g., quinoa or grain bowls). | Contaminants: Metal, stone, hard plastic, ceramic, or glass.

Missing Components: Sauce, dip, or gravy; utensils. |

Fresh Ready Meals | Fresh pre-packaged sandwiches, fresh ready-to-eat bowls (grain, rice, or noodle bowls). | Foreign Objects: Bone fragments (for sandwiches).

Contaminants: Metal, stone, hard plastic, ceramic, or glass.

Missing Components: Sauce, dip, or gravy; utensils. |

Ready-to-Eat Breakfast | Microwaveable breakfast bowls (scrambled eggs w/ sausage, oatmeal), pre-packaged breakfast sandwiches. | Contaminants: Metal, stone, hard plastic, ceramic, or glass. |

Vegetarian/Vegan Meals | Vegan meal kits and bowls, vegetarian and vegan frozen meals (vegan lasagna, tofu stir-fry). | Contaminants: Metal, stone, hard plastic, ceramic, or glass. |

Specialized Applications for Every Production Line

The versatility of modern X-ray technology allows for tailored solutions across various sectors:

1. Frozen and Microwaveable Solutions

A Frozen Meals x-ray machine must account for the "product effect" of ice and frozen densities. Similarly, a Microwaveable Meals x-ray machine is optimized to detect missing sauce sachets or plastic forks often included in these convenience packs.

2. Canned Goods and Seafood

For high-speed canning lines, a Canned Ready Meals x-ray machine or a Canned Fish and Seafood x-ray machine provides side-view or dual-beam inspection to see through thick metal walls and detect tiny bone fragments or lead shot that traditional sensors might miss.

3. Fresh and Plant-Based Meals

Maintaining the "fresh" image requires perfection. A Fresh Ready Meals x-ray machine or a Ready-to-Serve Salads x-ray machine ensures that no stones from the field or plastic from the harvester reach the consumer. For the growing market of meat alternatives, a Vegetarian and Vegan Ready Meals x-ray machine provides the rigorous screening needed to maintain the integrity of clean-label products.

4. Breakfast and Multi-Component Trays

A Ready-to-Eat Breakfast Meals x-ray machine is designed to handle heterogeneous mixtures like eggs, sausages, and hash browns, ensuring each component is present and free of contaminants.

Advanced AI and UHD Technology: The RaymanTech Advantage

As technology evolves, simply "seeing" isn't enough; "understanding" the image is the new standard. Leading systems now incorporate AI-driven algorithms and Ultra High Definition (UHD) Resolution.

● AI Inspection: Moves beyond simple thresholding to recognize patterns, significantly reducing false rejects in complex products like mixed salads or layered lasagna.

● UHD Detectors: Use the industry's highest resolution sensors to catch micro-contaminants that were previously undetectable, such as tiny glass shards or thin wire.

Frequently Asked Questions (FAQs)

Q: Is X-ray inspection safe for the food?

A: Absolutely. The radiation levels used in a Ready Meals x-ray machine are extremely low. Scientific studies by the WHO and FDA have confirmed that X-raying food does not affect its safety, nutritional value, flavor, or texture. The food does not become radioactive.

Q: Can X-ray machines detect plastic?

A: X-ray systems can detect "hard" or "dense" plastics (like PVC or nylon). However, low-density plastics (like thin films or hairnets) are generally not detectable. For the best results, we recommend a test of your specific product.

Q: How does X-ray compare to a metal detector for ready meals?

A: X-ray is superior for ready meals because it is not affected by "product effect" (moisture, salt, or temperature) and can see through aluminum foil packaging. It also provides quality checks (like counting components) that a metal detector cannot perform.

Q: What is the maintenance like for a commercial Ready Meals x-ray machine?

A: Modern machines are designed for the food environment with IP66 or IP69K ratings for easy washdown. Routine maintenance involves checking the cooling system and ensuring the X-ray tube is functioning within its expected lifespan.

Q: Does the machine slow down my production line?

A: No. High-speed X-ray systems can keep up with lines running hundreds of packs per minute, performing real-time analysis and automatic rejection without halting flow.

Conclusion

Choosing the right Ready Meals X-ray inspection machine manufacturer is the first step toward a safer, more efficient production line. By implementing specialized solutions—from a Frozen Meals x-ray machine to a Canned Ready Meals x-ray machine—you protect your consumers, comply with HACCP and SQF standards, and ensure your brand remains a trusted name in every kitchen.

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057