Dairy Products

RaymanTech provides inspection and sorting solutions for a wide range of dairy products—whether in powder, liquid, semi-liquid, or semi-solid form. These solutions apply to both unpackaged products and packaged ones, including glass bottles, metal cans, aluminum foil packs, and Tetra Paks.

REQUEST A QUOTE

Capabilities

-

Safety: Contaminants

Foreign contaminants such as metal, plastic, and sand can enter dairy products during raw material collection, transportation, or storage. They may also originate from equipment wear, packaging damage, or human error.

X-Ray machines and optical sorters play a vital role in ensuring dairy product safety. They deliver fast, accurate, and non-destructive detection and removal of contaminants—including metals, plastics, sand, and those with color and shape variations—effectively reducing both mechanical and human errors. High-resolution imaging precisely distinguishes contaminants from good products, ensuring every batch meets stringent quality standards. -

Quality Upgrade

Improper or incomplete sealing in dairy products can cause leakage or spoilage, compromising safety and quality. Production deviations may lead to missing components, misalignment, or deformation, while clumping in powdered products reduces flowability and inconsistent filling affects uniformity.

X-Ray inspection systems precisely assess seal integrity and detect cracks, missing parts, and deformations. For powdered products, they identify clumping and monitor filling levels to prevent over- or underfilling. These capabilities improve efficiency, ensure consistent quality, prevent non-compliant products from reaching the market, and reinforce brand reputation. -

CCP: SUS Sieve Mesh Wire

In dairy production, SUS sieve mesh is prone to wear and cracking over time, and fine wires may enter the product, posing serious risks to consumers. Due to their extremely small size, these wires are difficult for most inspection systems to detect.

Compared with traditional metal detectors, AI X-Ray inspection systems use advanced high-definition imaging and deep-learning technology to accurately detect tiny metal fragments, including SUS sieve mesh wires. These systems overcome challenges faced by traditional metal detectors—such as low-magnetic stainless steel, mesh wire orientation, and interference from metal packaging—ensuring superior detection accuracy and uncompromised product safety.

whole chain solution

Dairy Products

Metals, Stones, Glass

Plastics, Epoxy Paints, Ceramics

Missing and Defects

Sieve Mesh Wires

Clumping/Agglomeration

Filling Capacity

Seal Clip

Metal Can (Metal in Metal)

Glass Bottle (Glass in Glass)

Industrial Applications

Explore by industry - access for more information.

-

Packaged Milk Powder

More information -

Canned Milk Powder

More information -

Ice Cream

More information -

Yogurt

More information -

Big Cheese Block

More information -

Various Cheese

More information -

Butter/Margarine

More information -

Cream

More information

Get in Touch!

For your dairy products inspection & sorting solutions!

Contact

For your dairy products inspection & sorting solutions!

Related Machines

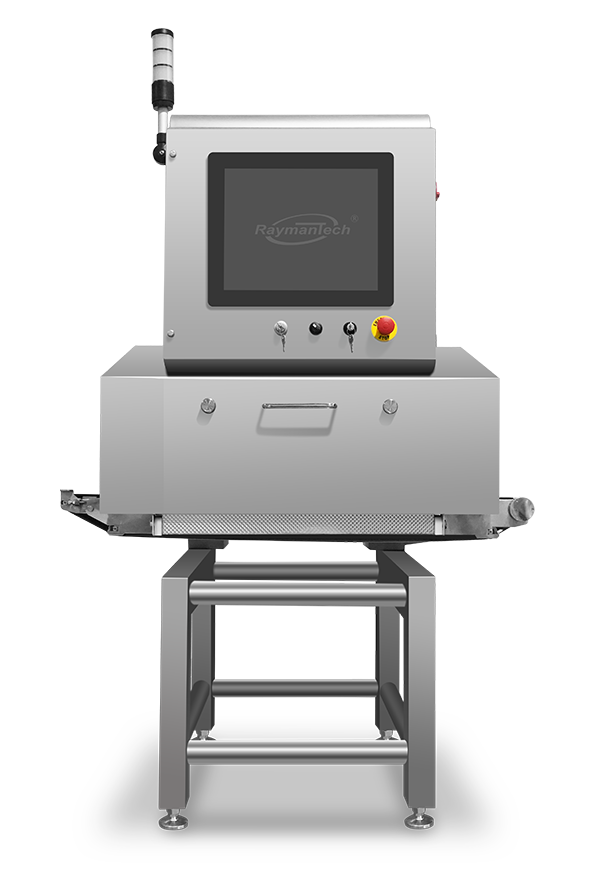

X-Ray Inspection Systems

Optical Sorting Systems

-

UHD X-Ray System

AI-powered UHD detector technology

Adaptable resolution technology

Ultra-fine contaminant inspection

IP67 for inspection tunnel

-

X-Ray for Can Bottle Jar

.png)

Metal in metal detection

Glass in glass detection

Filling level detection

Full area container detection

-

AI X-Ray

Contaminant identification

Defect detection

Seal inspection

Real-time data processing

-

AI Multi Beam Sorter

For dry/wet/frozen materials

Multi-view imaging

-

AI Medium Speed Sorter

.png)

Contaminants and defects sorting

Tiny impurity (hair) sorting

For wet and high-dust environments

For fragile or delicate products

-

AI Top View Sorter

For small particles/flat products

Top single, double, or triple view

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

© 2015-2025 RaymanTech - Privacy Policy - Term of Use