Bakery

High-precision inspection solutions designed for the bakery industry, covering frozen dough, baked products, and raw ingredients. Our systems deliver reliable detection of foreign contaminants, product defects, and packaging errors throughout the entire production line.

REQUEST A QUOTE

Capabilities

-

Safety: Contaminant Detection

In bakery production, foreign contaminants often arise from equipment wear, packaging damage, or operational error. Typical contaminants include metal, glass, and plastic, while natural impurities in raw materials—such as stones or soil from flour and sugar—can also enter the process.

X-Ray inspection and optical sorting technologies provide comprehensive protection across every stage of production. From raw materials to processing and final packaging, they precisely detect and remove contaminants and impurities, ensuring every product meets the highest safety and quality standards. These technologies not only enhance efficiency and reduce manual intervention but also strengthen food safety and protect brand reputation. -

Quality Upgrade

During production, bakery products may develop appearance defects or surface damage due to inaccurate temperature control or improper baking time. Incomplete tray filling often results from incorrect automation settings or unstable production lines. Missing desiccants or oxygen absorbers typically arise from material handling issues or operational errors, while barcode misprints or faulty seals usually occur due to equipment misalignment or material variations.

X-Ray and vision inspection technologies deliver precise, automated quality control across the entire production process. They detect product defects, filling inconsistencies, appearance flaws, and package errors—enhancing production efficiency, minimizing human error, ensuring regulatory compliance, and strengthening brand reliability. -

X-Ray vs. Metal Detector

Baked products often contain oil and high salt levels, and their elevated temperatures during production can interfere with metal detector signals. In addition, wider conveyor lines and slower production speeds make it challenging for metal detectors to operate at peak efficiency. This issue also happens when aluminum foil packaging is used, as balanced coil metal detectors cannot function effectively, resulting in reduced detection accuracy.

X-Ray inspection solutions overcome these challenges by detecting metals with high precision and identifying other contaminants such as glass, plastic, and stones—regardless of oil, salt, packaging, or temperature. With high sensitivity and advanced imaging, they also detect irregular shapes and internal defects, ensuring product safety, consistent quality, and reliable quality control.

whole chain solution

Bakery Industry

• Metals, Stones, Glass

• Deoxidizers/Desiccants Missing

• Correct Filling of Products

• Damages, Breaks, Cracks

• Deformed Shapes

• Seal Clip

• Mixed-in Metal Parts

• Ingredients & Raw Materials Inspection & Sorting

• Seal Clip

• Barcode Verification

Industrial Applications

Explore by industry - access for more information.

-

Cookies/Biscuits

More information -

Bread

More information -

Rolls/Croissants

More information -

Pastries

More information -

Cakes/Cupcakes

More information -

Muffins/Scones

More information -

Pizza Crusts

More information -

Frozen Dough

More information

Get in Touch!

For your bakery inspection & sorting solutions!

Contact

For your bakery inspection & sorting solutions!

Related Machines

X-Ray Inspection Systems

Optical Sorting Systems

-

AI X-Ray

Contaminant identification

Defect detection

Seal inspection

Real-time data processing

-

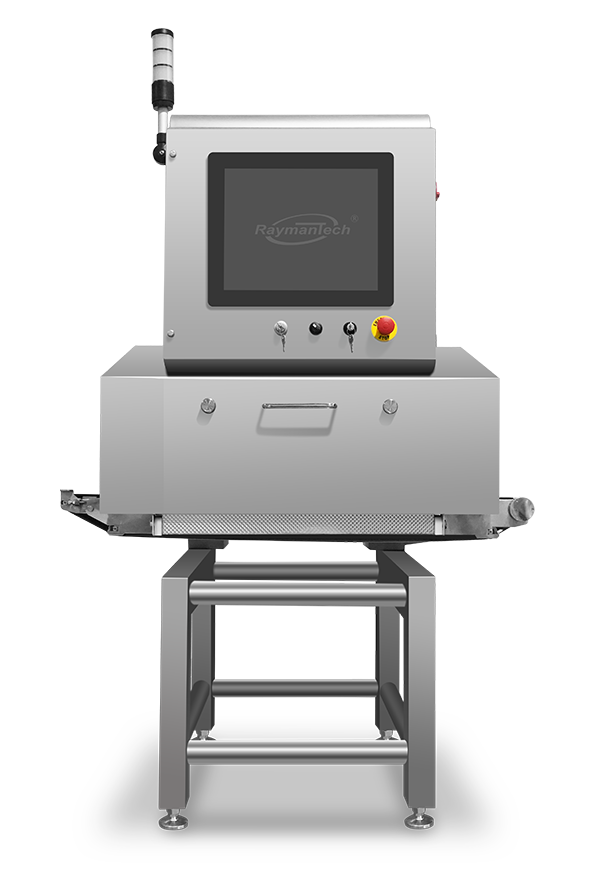

Compact Economical X-Ray

AI-powered high resolution detector

IP67 for Inspection tunnel

IP69K full body optional

Defect and missing inspection

-

UHD X-Ray System

AI-powered UHD detector technology

Adaptable resolution technology

Ultra-fine contaminant inspection

IP67 for inspection tunnel

-

AI Medium Speed Sorter

.png)

Contaminants and defects sorting

Tiny impurity (hair) sorting

For wet and high-dust environments

For fragile or delicate products

-

AI Multi Beam Sorter

For dry/wet/frozen materials

Multi-view imaging

-

AI Top View Sorter

For small particles/flat products

Top single, double, or triple view

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

© 2015-2025 RaymanTech - Privacy Policy - Term of Use