Ready Meals

Comprehensive inspection and sorting solution for ready-to-eat meals and convenience foods, covering raw materials, processed and finished products to ensure safety and enhance quality.

REQUEST A QUOTE

Capabilities

-

Safety: Contaminants

Ready meals, designed for quick preparation and consumption, face potential risks of foreign objects and impurities throughout raw material handling and processing. Vegetables may contain metal shards, glass fragments, sand, stones, pests, or plant debris, while meat may include bone fragments. During production, equipment wear or component detachment can cause metal contamination, and damaged packaging may introduce glass or plastic fragments. These contaminants not only compromise product quality but also pose safety risks and harm brand reputation.

X-Ray inspection and optical sorting technologies provide an effective solution to these challenges. They accurately detect and remove foreign objects and impurities at every production stage, ensuring defective materials are eliminated in real time. With continuous monitoring and automated sorting, production efficiency is enhanced, manual intervention is reduced, and every product meets the highest standards of food safety and quality. -

Quality Upgrade

The ready meal industry faces continuous challenges in ensuring consistency, integrity, and accuracy. Defects in raw materials, packaging dents or deformation, and missing components such as sauce packets or utensils can all reduce consumer satisfaction. Improper sealing or foreign material may lead to leakage and spoilage, while coding or labeling errors can compromise traceability and compliance.

The integration of X-Ray inspection, optical sorting, and vision inspection technologies offers a comprehensive solution to these challenges. By monitoring every stage—from raw material processing to final packaging—these systems precisely detect and eliminate quality defects and packaging issues in real time. Automated inspection enhances efficiency, reduces human error, minimizes safety risks, and ensures every ready meal meets the highest standards of quality, safety, and consumer satisfaction. -

Driving Long-Term Success

In ready meal production, quality and safety management are essential to protecting consumer health. As convenient foods become an integral part of modern lifestyles for busy urban residents, children, the elderly, and other special groups, the demand for reliable, high-quality products continues to rise. Ensuring strict control at every stage—from raw materials to production and packaging—helps prevent contamination, foreign object intrusion, and other potential safety risks.

By integrating advanced technologies such as X-Ray inspection, optical sorting, and vision inspection, manufacturers can achieve real-time quality monitoring, quickly identify and resolve issues, and continuously optimize production processes. These technologies help food producers reduce operational risks, enhance brand reputation, and drive long-term growth and competitiveness in the marketplace.

whole chain solution

Ready Meals

• Metals, Stones, Plastics, Ceramics, Glass

• Bone Fragments

• Missing Parts

• Inserts/Dividers Missing

• Dented/Deformed Cans

• Ingredients/Raw Material Inspection & Sorting

• Seal Clip

• Barcode Verification

Industrial Applications

Explore by industry - access for more information.

-

Microwavable Entrées

More information -

Frozen Pasta Dishes

More information -

Frozen Pizzas

More information -

Canned Meals

More information -

Packaged Salad Kits

More information -

Ready Sandwiches

More information -

Fresh RTE Bowls

More information -

RTE Meal Kits

More information

Get in Touch!

For your ready meals inspection & sorting solutions!

Contact

For your ready meals inspection & sorting solutions!

Related Machines

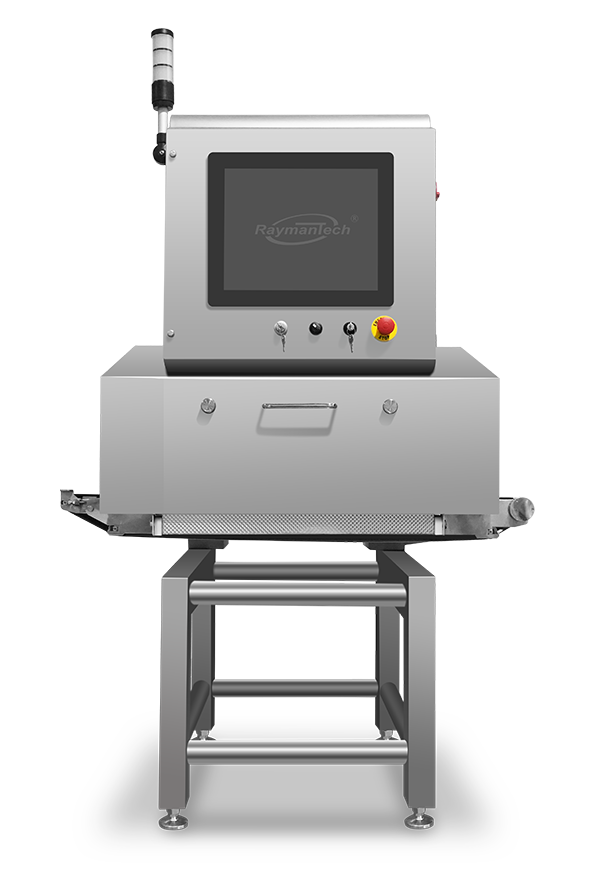

X-Ray Inspection Systems

Optical Sorting Systems

-

UHD X-Ray System

AI-powered UHD detector technology

Adaptable resolution technology

Ultra-fine contaminant inspection

IP67 for inspection tunnel

-

X-Ray for Can Bottle Jar

.png)

Metal in metal detection

Glass in glass detection

Filling level detection

Full area container detection

-

AI X-Ray

Contaminant identification

Defect detection

Seal inspection

Real-time data processing

-

AI Medium Speed Sorter

.png)

Contaminants and defects sorting

Tiny impurity (hair) sorting

For wet and high-dust environments

For fragile or delicate products

-

AI Multi Beam Sorter

For dry/wet/frozen materials

Multi-view imaging

-

AI Top View Sorter

For small particles/flat products

Top single, double, or triple view

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

© 2015-2025 RaymanTech - Privacy Policy - Term of Use