Pet Food

Comprehensive inspection solution for pet food—detects foreign contaminants, defects, and packaging issues across raw, processed, and packaged products.

REQUEST A QUOTE

Capabilities

-

Safety: Contaminants

Pet food production involves a wide range of ingredients—such as meat, fish, grains, vegetables, and fruits—that can be exposed to foreign contaminants including bone fragments, metal pieces, glass shards, plastic particles, sand, or soil. These risks often arise from variations in raw materials, equipment wear, or packaging damage during processing.

Advanced X-Ray inspection and optical sorting technologies provide comprehensive protection against such contaminants throughout the entire production process. From raw material intake to final packaging, these systems precisely detect and eliminate foreign objects at critical control points. By maintaining the highest standards of safety and quality while improving production efficiency, manufacturers can safeguard pets’ health, reinforce brand trust, and strengthen competitiveness in the market. -

Quality Upgrade

Pet food production faces quality challenges, including issues that appear as shape and color deviations, missing key components (desiccants or oxygen absorbers), and packaging problems (dents, deformation, or improper sealing). These problems can compromise product quality, pose risks to pet health, and affect consumer trust.

X-Ray inspection and optical sorting technologies provide precise, automated quality control. They detect defects, verify key components, and ensure packaging integrity, preventing non-compliant products from reaching the market. By improving production efficiency and safeguarding product quality, these solutions help manufacturers strengthen consumer trust and brand reputation. -

Driving Long-Term Success

Pets have low tolerance for foreign objects, and even small contaminants can seriously affect their health. As indirect consumers, pet owners may not notice when their pets experience discomfort from foreign objects or quality issues, making timely feedback to manufacturers difficult. For this reason, production management need to prioritize safety and quality monitoring to ensure every batch meets strict standards.

In large-scale pet food production, X-Ray and optical sorting technologies play a crucial role in detecting foreign objects and maintaining consistent quality. By implementing efficient inspection systems, potential contaminants are identified and removed early, preventing quality issues from affecting entire batches, protecting pets’ health, and enhancing consumer trust.

whole chain solution

Pet Food

• Metals, Stones, Plastics, Ceramics, Glass

• Bone Fragments

• Sieve Mesh Wires

• Desiccants/Deoxidizers Missing

• Discoloration and Irregular Shape

• Ingredients/Raw Material Inspection & Sorting

• Seal Clip

• Barcode Verification

Industrial Applications

Explore by industry - access for more information.

-

Dry/Dehydrated Pet Food

More information -

Frozen Pet Food

More information -

Pet Treats and Biscuits

More information -

Wet (Canned) Pet Food

More information

Get in Touch!

For your pet food inspection & sorting solutions!

Contact

For your pet food inspection & sorting solutions!

Related Machines

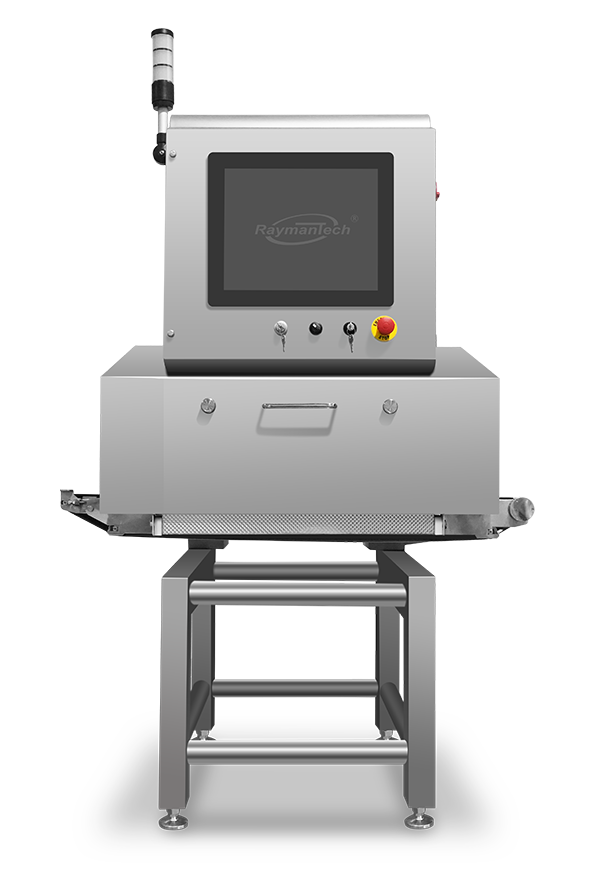

X-Ray Inspection Systems

Optical Sorting Systems

-

UHD X-Ray System

AI-powered UHD detector technology

Adaptable resolution technology

Ultra-fine contaminant inspection

IP67 for inspection tunnel

-

X-Ray for Can Bottle Jar

.png)

Metal in metal detection

Glass in glass detection

Filling level detection

Full area container detection

-

AI X-Ray

Contaminant identification

Defect detection

Seal inspection

Real-time data processing

-

AI Medium Speed Sorter

.png)

Contaminants and defects sorting

Tiny impurity (hair) sorting

For wet and high-dust environments

For fragile or delicate products

-

AI Multi Beam Sorter

For dry/wet/frozen materials

Multi-view imaging

-

AI Top View Sorter

For small particles/flat products

Top single, double, or triple view

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

© 2015-2025 RaymanTech - Privacy Policy - Term of Use