Introduction to RaymanTech Optical Sorters for Farm Products and Food Processors

RaymanTech, as a leading provider of inspection an...

More

The carrot processing industry is transforming, with 30% of new 2025 products featuring clean-label claims. Large-scale processors favor the TOMRA 5B and Key Technology VERYX B175 for speed. Meanwhile, the Bühler SORTEX F and Newtec Celox-C-UHD provide precision for premium lines, supported by other specialized carrots sorting machine options.

Choosing the right sorting technology is a critical investment for any carrot processor. The following detailed reviews break down the top 10 machines, highlighting their unique strengths, ideal applications, and technological advantages to guide your decision-making process.

The TOMRA 5B is an industry titan, engineered for high-volume processors who demand both speed and precision. This belt sorter uses a combination of advanced laser, camera, and smart surround-view technology to inspect products in-flight. This allows it to analyze all sides of each carrot, ensuring superior detection of color defects, blemishes, and foreign material.

Its primary strength lies in maximizing throughput without sacrificing quality. The machine efficiently removes imperfections, leading to a higher yield of saleable product and a significant reduction in food waste. While it excels with carrots, its versatile design also accommodates other vegetables like peas, green beans, and corn.

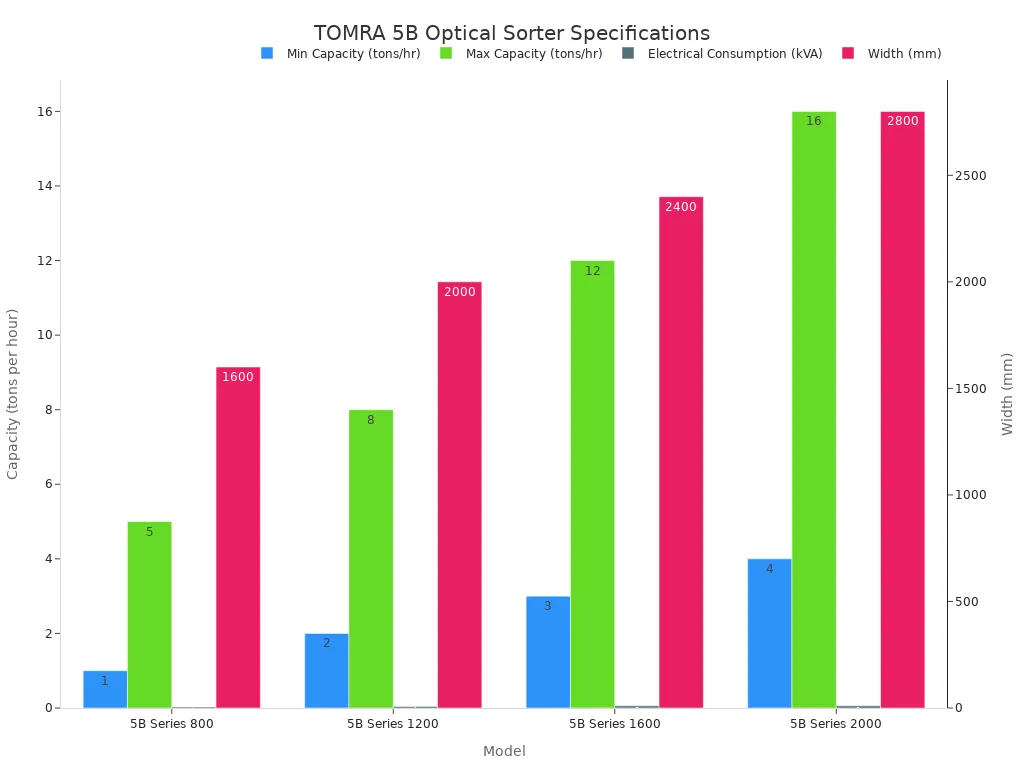

Note: The TOMRA 5B is available in several models to match different production scales. Processors can select a machine that aligns perfectly with their capacity needs.

| TYPE | 5B Series 800 | 5B Series 1200 | 5B Series 1600 | 5B Series 2000 |

|---|---|---|---|---|

| Capacity | 1 – 5 tons/hr | 2 – 8 tons/hr | 3 – 12 tons/hr | 4 – 16 tons/hr |

| Dimensions (LxWxH) | 4.1m x 1.6m x 2.95m | 4.1m x 2.0m x 2.95m | 4.1m x 2.4m x 2.95m | 4.1m x 2.8m x 2.95m |

| Electrical Consumption | 5 kVA | 7.5 kVA | 10 kVA | 10 kVA |

Key Technology's VERYX B175 is a direct competitor to the TOMRA 5B, built for large-scale industrial applications. It distinguishes itself with a powerful AI-driven inspection system and a wide 1750mm inspection zone. The machine's architecture provides a comprehensive top-and-bottom view of the product stream, eliminating blind spots.

The VERYX platform is highly modular. Processors can configure it with a range of sensors, including high-resolution cameras and lasers, to target specific defects unique to their product. Its advanced AI algorithms learn and adapt in real-time, improving sorting accuracy over time and minimizing the need for manual adjustments. This makes it an excellent choice for factories processing massive quantities of carrots for freezing, canning, or dicing.

The Bühler SORTEX F is synonymous with precision and quality control. This machine is a top choice for producers of premium and fresh-market carrots where aesthetic perfection is paramount. It utilizes a suite of specialized technologies to achieve unparalleled defect detection.

SORTEX F PolarVision™: This system excels at identifying and removing foreign materials, detecting plastics, wood, and glass as small as 0.6 mm.

SORTEX F BioVision™: This technology targets color and shape defects with incredible accuracy. It can identify subtle discoloration, rotten spots, and misshapen carrots, detecting flaws as small as 2 mm.

The reliability of Bühler technology is validated by industry leaders. Dirk Verhelle, owner of frozen vegetable producer Westfro, chose Bühler for a new facility after years of positive experience. He states, "The reliability and efficiency of Bühler’s SORTEX technology, combined with the excellent local support...meant that we wanted to continue the relationship as our business expands." At Westfro, the sorters handle 24 tons per hour, demonstrating that high precision does not have to come at the expense of throughput.

Newtec engineered the Celox-C-UHD specifically for the demands of high-quality carrot sorting. This machine focuses on providing a complete and detailed analysis of every single carrot. Its standout feature is an advanced camera system that inspects each carrot from three different angles (two above, one below) to ensure full 360° surface coverage.

The system incorporates several key innovations:

Tilted Camera Section: This unique design provides a better view of the carrot's ends, dramatically improving the detection of tip rot.

Homogeneous LED Lighting: Repositioned light bars create consistent illumination, ensuring accurate grading across all lanes.

Intelligent Software: The software can identify "double carrots" and grade each part separately, optimizing yield by preventing the unnecessary rejection of good product.

This meticulous approach makes the Celox-C-UHD the ideal carrots sorting machine for producers supplying demanding retail markets.

Versatility is the hallmark of the Unitec Carrot Vision 3. This system is designed to adapt to any carrot variety, regardless of size or shape. It provides processors with a powerful tool to sort based on a comprehensive set of quality parameters, ensuring a consistent and high-quality final product.

The Carrot Vision 3 system accurately classifies carrots based on:

External Quality: Detects cracks, breaks, and cuts.

Color Defects: Identifies greening and black spots.

Shape Defects: Sorts out curved or bifurcated (forked) carrots.

Size & Diameter: Grades carrots precisely by length and width.

This ability to handle diverse products and sort by multiple criteria simultaneously makes it a flexible solution for operations that process different carrot varieties for various markets.

MAF Roda Agrobotic brings the power of artificial intelligence and robotics to the forefront of carrot sorting. This system is more than just a sorter; it is a complete quality analysis platform. It uses high-resolution cameras operating across multiple light spectra (infrared and visible) to conduct a 100% surface scan of each carrot.

The integration of AI allows the system to achieve exceptional accuracy in defect recognition. The machine learns to identify subtle imperfections and can adapt to variations in product quality, reducing human error and boosting sorting precision. MAF Roda's focus on data-driven analysis provides processors with deep insights into their product quality, making it a forward-thinking choice for technologically advanced operations.

The Raytec Dryce is a specialized sorter designed for challenging applications. While many sorters focus on fresh, whole products, the Dryce excels at sorting processed, frozen, or dehydrated carrots. It uses dual-camera technology to inspect product on the belt, effectively identifying color defects, rotten pieces, and foreign bodies. Its robust build and simple user interface make it a reliable workhorse in demanding factory environments where consistency and safety are top priorities. This carrots sorting machine is ideal for producers of frozen carrot mixes, dehydrated soup ingredients, or other value-added carrot products.

Gentle handling is the core principle behind the Greefa GeoSort. Originally designed for delicate fruits like apples and kiwis, its technology is perfectly suited for preserving the quality of fresh-market carrots. The machine is engineered to minimize drops and impacts at every stage of the sorting process.

The GeoSort is the company’s most productive and fruit-friendly sorting machine...[it can] process up to 8 fruits per second per lane, maintaining speed and consistency while gently handling even the most sensitive produce.

This focus on gentle handling ensures that carrots arrive at packaging without bruises, cracks, or other mechanical damage. For producers whose brand reputation depends on delivering visually perfect, farm-fresh carrots, the GeoSort is an outstanding choice.

The Aweta G-8 strikes a balance between high capacity and precise quality control. This roller sorter is built for durability and is capable of handling large volumes of carrots efficiently. It uses a combination of high-definition cameras and advanced software to sort carrots based on size, color, shape, and external quality. The G-8 is known for its reliability and consistent performance, making it a popular choice for medium to large-scale packing houses that need a dependable system to meet daily production targets without compromising on quality standards.

The Duravant WECO T-12 is built for raw power and throughput. This machine is designed for the initial stages of processing, where high volumes of field-run carrots need to be sorted quickly. It uses a robust mechanical design combined with effective optical sorting to remove foreign material, gross defects, and undesirable sizes. While it may not offer the fine-tuned precision of premium sorters, its strength lies in its ability to handle immense capacity, making it an essential piece of equipment for the largest industrial processors who need to clean and pre-sort product before it moves to downstream processing lines.

Understanding the differences in speed, accuracy, and application is crucial for selecting the right equipment. This analysis breaks down how the top models stack up against each other in key performance areas.

Processing speed directly impacts operational efficiency and output. High-volume industrial machines like the TOMRA 5B and Key Technology VERYX B175 are engineered for maximum throughput, handling many tons per hour. Other models quantify speed by the number of individual carrots processed. The Newtec Celox-C-UHD, for example, demonstrates scalable capacity based on its configuration.

| Machine Model | Lanes | Carrots per Hour | Carrots per Minute |

|---|---|---|---|

| Newtec Celox-C-UHD | 4 | 50,000 | 833 |

| Newtec Celox-C-UHD | 8 | 100,000 | 1,667 |

| Newtec Celox-C-UHD | 12 | 150,000 | 2,500 |

This data shows how processors can match machine size to their specific volume needs.

Modern sorters use advanced imaging and AI to identify a wide range of imperfections. Premium systems like the Bühler SORTEX F and Unitec Carrot Vision 3 excel at detecting subtle flaws. Their machine learning algorithms can spot common issues with high precision.

Common Defects Identified by Advanced Sorters:

Cracks & Breakage: Structural damage from harvesting or handling.

Green Head/Greenroot: Discoloration from sun exposure.

Bifurcation: Forked or misshapen carrots.

Beyond product quality, systems like the Bühler SORTEX F use specialized sensors to find and remove foreign materials, ensuring food safety.

The ideal carrots sorting machine depends entirely on the operational scale.

Small-Scale Farms: Growers and small packers benefit from tailored systems. Companies like Wyma Solutions offer a 'Small Carrot Line' designed for lower volumes, providing efficiency without a massive footprint.

Large Industrial Plants: Processors producing frozen or canned goods need robust, high-capacity equipment. Manufacturers like Vanmark and Bühler build durable, automated lines optimized for continuous, high-volume production and strict sanitation standards.

Selecting the right equipment requires a thorough evaluation beyond the initial specifications. Processors must consider long-term value, technological capabilities, and operational integration to ensure a successful investment.

The sticker price of a sorter is only one part of the financial picture. A comprehensive analysis of the Total Cost of Ownership (TCO) provides a more accurate assessment of the long-term financial impact. Key factors include:

The initial purchase price

Installation and setup costs

Ongoing maintenance expenses

Daily energy consumption

Potential costs from operational downtime

A strong return on investment (ROI) often justifies the initial expense. For commercial vegetable processing equipment, payback periods typically range from 2 to 5 years. Many businesses achieve a full ROI within 2 to 3 years by leveraging labor savings and increased production volume.

Modern software transforms a sorter from a mechanical tool into an intelligent data hub. Artificial intelligence (AI) dramatically improves sorting precision. Advanced deep neural networks can achieve an accuracy rate of 99.43%, automatically removing defective items to reduce food waste. This ensures only healthy produce reaches the consumer.

Beyond sorting, these systems provide valuable production analytics. They offer remote monitoring of machine status and automatically record sorting data for each carrot. This information can be exported for deeper analysis, helping managers optimize production and improve quality control.

A new carrots sorting machine must fit seamlessly into an existing production line. Processors must carefully consider the physical footprint and utility requirements, including power and air, to ensure compatibility with the plant layout.

Key Maintenance Practices:Regular upkeep is essential for preventing downtime. This includes scheduled daily cleaning, checking that cutting blades remain sharp, and calibrating sensors according to manufacturer guidelines.

Choosing a supplier that guarantees easy access to spare parts is equally critical. A reliable parts supply chain is the best defense against extended production halts, protecting the initial investment and maintaining operational continuity.

Selecting the right carrots sorting machine requires aligning its capabilities with your operational scale and quality standards. Industrial processors favor the TOMRA 5B and Key Technology VERYX B175 for maximum throughput. Operations prioritizing precision often choose the Newtec Celox-C-UHD or Bühler SORTEX F. This guide's analysis helps businesses weigh each model's strengths for a confident investment.

Processors often achieve a full return on investment within 2 to 5 years. Key drivers include significant labor savings, increased throughput, and higher overall product yield.

Advanced sorters use specialized cameras to detect and remove foreign materials. This process eliminates contaminants like plastic, wood, or glass, ensuring a much safer final product. ✅

Regular upkeep is crucial for performance. It includes daily cleaning, sensor calibration, and blade checks. A reliable parts supply from the manufacturer prevents extended operational downtime.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Ultra-fine contaminants detection, UHD X-Ray detec...

Recommedation: Aquatic products, pet food, candy, ...

Recommedation: Chili, walnut, peanuts, soybeans, c...

Both fat analysis and contaminant inspection (bone...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

RaymanTech, as a leading provider of inspection an...

MoreIn the fast-paced world of food production, ensuri...

MoreFood safety and quality control demands have evolv...

MoreIn food processing, the highest-risk moment isn’t ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Farm ManagerThis carrots sorting machine has revolutionized our harvesting process. The accuracy and speed are incredible - we've reduced waste by 40% and increased our daily output significantly. The automated grading system is perfectly calibrated for carrot size and quality.

Sarah Chen

Food Processing SupervisorAs a large-scale vegetable processor, we needed reliable equipment that could handle high volumes. This sorting machine delivers consistent performance with minimal maintenance. The color recognition technology effectively separates premium carrots from lower grades. One star off for the steep learning curve.

David Thompson

Organic Farm OwnerPerfect for our organic carrot operation! The gentle handling system prevents bruising, and the customizable settings allow us to sort based on our specific quality standards. The machine pays for itself in reduced labor costs and improved product consistency.

Jennifer Williams

Quality Control ManagerThe precision of this sorting machine is outstanding. It detects subtle defects we used to miss with manual sorting. Integration with our packaging line was seamless, and the real-time data analytics help us optimize our entire production workflow. Highly recommended for any serious carrot producer.