Confectionery

Whole chain inspection and sorting solutions for bulk and packaged confectionery—ensuring safety and quality at every stage.

REQUEST A QUOTE

Capabilities

-

Safety: Contaminants

In the confectionery industry, contaminants such as metal and glass are often caused by equipment wear, packaging damage, or operational errors. Additionally, small impurities like stones, hair, sand, or plastic may come from raw material impurities, environmental contamination, or accidental mixing during production.

X-Ray inspection and optical sorting technologies play a vital role in ensuring product safety. They accurately detect and remove both common contaminants and tiny impurities, even in products with complex shapes. With exceptional sensitivity and automated removal systems, these technologies enhance production efficiency, reduce manual intervention, strengthen quality control, and ensure every batch meets the highest safety standards. -

Quality Upgrade

In the confectionery industry, consistent product quality is essential to meet consumer expectations. Common issues such as incomplete filling, missing components, color variation, irregular shapes, cracks, sticking, and packaging defects often result from equipment malfunctions or raw material inconsistencies.

X-Ray inspection and optical sorting technologies precisely detect such defects and packaging irregularities, prevent color and shape errors, and maintain consistency during production line changes. By automating quality control and providing real-time analysis, these systems help stabilize production, ensure uniform product quality, and build consumer trust. -

Comprehensive Solution

Traditional inspection systems in the confectionery industry often focus only on finished products, making it difficult to identify foreign objects, impurities, or quality defects during raw material handling or production.

By combining X-Ray bulk detection with optical sorting technologies, this solution enables real-time detection of potential issues at the earliest production stages, ensuring quality control throughout the entire process. Detecting and removing contaminants and defects before packaging helps prevent contamination, minimize rework and recall risks, and protect brand reputation. In addition, it optimizes production flow, ensures consistent quality, and enhances customer satisfaction.

whole chain solution

Confectionery

• Metals, Stones, Plastics, Ceramics, Glass

• Missing and Defects

• Discoloration and Irregular Shape

• Correct Filling of Products

• Ingredients & Raw Materials Inspection & Sorting

• Seal Clip

• Barcode Verification

Industrial Applications

Explore by industry - access for more information.

-

Chocolate Bars

More information -

Chocolate Candies

More information -

Gummy Candies

More information -

Chewing Gum

More information -

Confectionery with Nuts

More information -

Marshmallows

More information -

Jelly Candies

More information -

Sugar/Candy Sprinkles

More information

Get in Touch!

For your confectionery inspection & sorting solutions!

Contact

For your confectionery inspection & sorting solutions!

Related Machines

X-Ray Inspection Systems

Optical Sorting Systems

-

AI X-Ray

Contaminant identification

Defect detection

Seal inspection

Real-time data processing

-

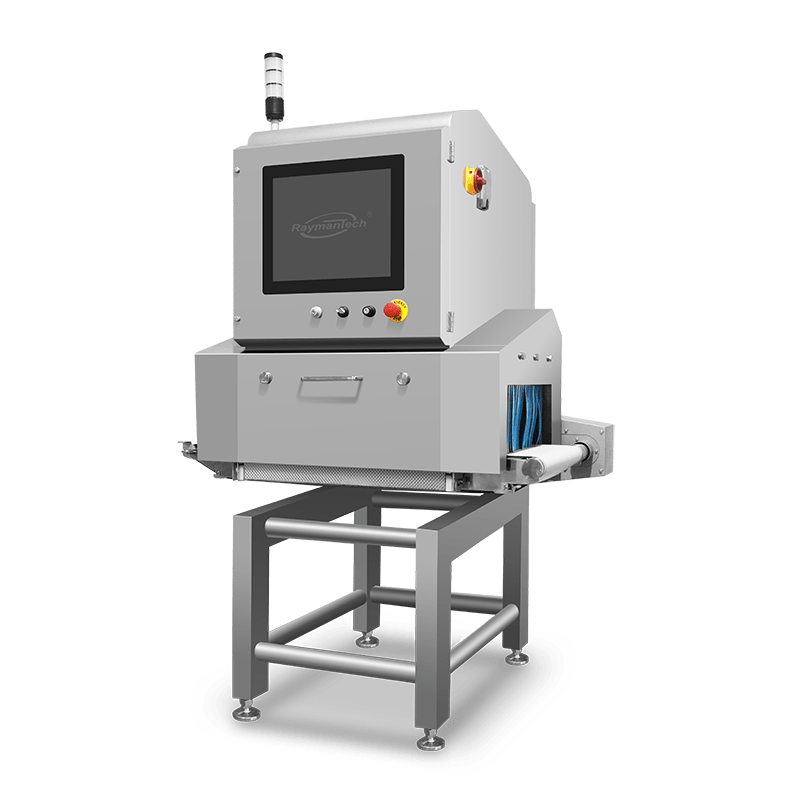

Compact Economical X-Ray

AI-powered high resolution detector

IP67 for Inspection tunnel

IP69K full body optional

Defect and missing inspection

-

X-Ray for Bulk Products

Small, tiny contaminant inspection

Low density contaminant inspection

Organic contaminant inspection

Shape inspection

Color sorting

-

AI Medium Speed Sorter

.png)

Contaminants and defects sorting

Tiny impurity (hair) sorting

For wet and high-dust environments

For fragile or delicate products

-

AI Top View Sorter

For small particles/flat products

Top single, double, or triple view

-

AI Standard Optical Sorter

High capacity

For dry/wet materials

For high-dust environments

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

© 2015-2025 RaymanTech - Privacy Policy - Term of Use