Principle of X-ray Inspection Machines in the Food Industry

X-ray inspection machines have become indispensabl...

More

Foreign object contamination is a persistent threat, causing 11.4% of U.S. food recalls from 2020-2024 and contributing to an estimated $7 billion annual economic impact.

A food electronics x ray machine provides a powerful solution. The system passes a low-energy beam through food on a conveyor. Denser contaminants like metal or glass absorb more energy, appearing as dark shadows on a final image for instant identification and rejection.

The effectiveness of a food electronics x ray machine stems from basic physics principles. The technology leverages how different materials interact with X-ray energy. This interaction allows the system to "see" through a food product and identify foreign objects based on their physical properties.

X-ray generation begins inside a sealed tube. This tube contains a cathode structure with a tungsten filament. An electrical circuit heats this filament, causing it to release electrons through a process called thermionic emission. These electrons form a cloud around the filament. When a high voltage is applied, the system accelerates the electrons toward an anode target. This high-speed collision generates a beam of X-rays. These systems typically use "hard X-rays" with energy levels greater than 5 kiloelectron volts (keV), which possess enough power to penetrate food products.

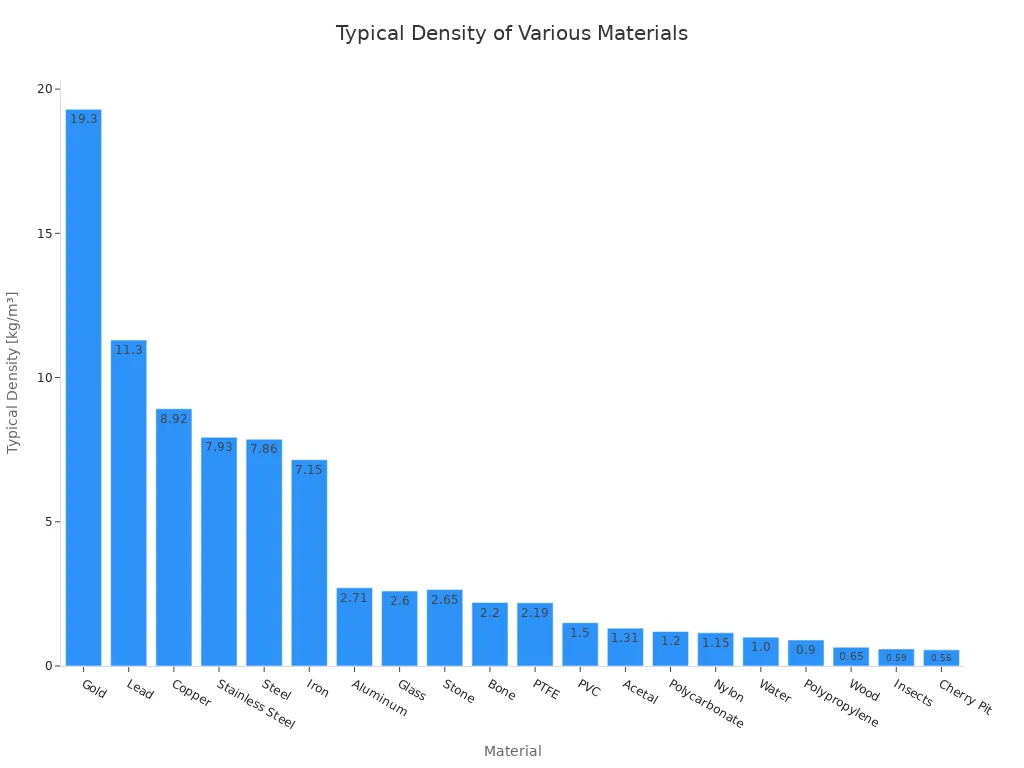

Differential absorption is the key to detection. It describes the varying degrees to which different materials absorb an X-ray beam. This absorption rate depends on a material's density and the atomic number of its elements. Food products mostly contain low-atomic-number elements like carbon and oxygen. Contaminants such as metal, glass, and bone have higher densities and atomic numbers. They absorb significantly more X-ray energy than the surrounding food.

This relationship is described by the Beer-Lambert law:

I = I0 * e^(-μt)In this equation, the final intensity (I) of the X-ray beam decreases exponentially based on the material's thickness (t) and its linear attenuation coefficient (μ), which is tied to density.

A detector on the opposite side of the product captures the remaining X-rays. This detector uses a two-step process:

Scintillation: A scintillator material absorbs the incoming X-ray photons and converts their energy into visible light.

Photodetection: An array of photodiodes then absorbs this light, converting it into an electrical charge.

The amount of charge in each photodiode corresponds to the X-ray intensity that reached it. Software processes these signals, assigning a grayscale value to each point. Areas where dense contaminants blocked more X-rays produce less charge and appear as darker shadows on the final image.

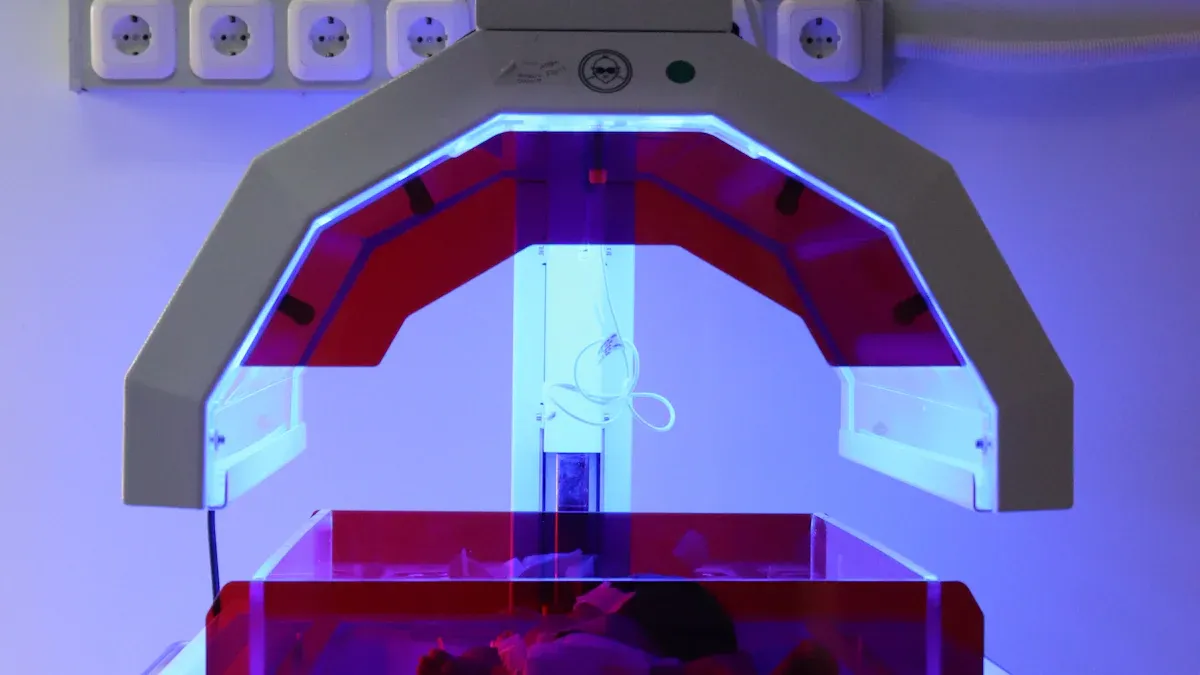

A food electronics x ray machine integrates several core components to create a seamless inspection process. Each part plays a specific role, from generating the X-ray beam to removing a contaminated product from the production line. Understanding this anatomy reveals how the system achieves its precision and reliability.

The system's heart is its X-ray generator and detector assembly. The generator produces a controlled X-ray beam aimed at the product. Opposite the generator, a highly sensitive detector captures the X-rays that pass through. Modern systems employ advanced detector technologies to achieve high-resolution images. These include:

CMOS Linear Diode Arrays (LDA)

Time-Delayed Integration (TDI) detectors

Single-energy and Dual-energy LDAs

Buttable silicon CMOS line scan detector boards

These components work together to convert X-ray energy into detailed digital data for analysis.

The conveyor system transports food products through the inspection tunnel at a constant, controlled speed. This steady movement is critical for accurate imaging. Any speed variations could distort the resulting image, potentially masking small contaminants or causing false rejections. The conveyor is designed to be radiolucent, meaning it does not significantly absorb X-rays, ensuring it does not interfere with the inspection of the food product itself.

Sophisticated image processing software acts as the brain of the food electronics x ray machine. It instantly analyzes the grayscale image from the detector, using complex algorithms to identify density variations that signal a contaminant.

Automated Decision-Making: When the software detects an anomaly corresponding to a predefined contaminant profile, it sends a signal to an automated rejection mechanism. This device, such as an air jet or a pusher arm, physically removes the single affected product from the conveyor belt with minimal disruption to the production flow.

A food electronics x ray machine offers capabilities far beyond simple metal detection. The technology identifies foreign bodies by analyzing density, allowing it to find a wide range of materials that could compromise product safety and quality. It also performs critical quality control functions, making it an invaluable tool on the production line.

While metal detectors are limited to ferrous and non-ferrous metals, X-ray systems detect a broader spectrum of contaminants. This includes dense materials like glass, mineral stone, and calcified bone. Advanced dual-energy systems enhance this capability by using two simultaneous X-ray energy levels. This technology subtracts the resulting images to isolate low-density foreign bodies, such as certain plastics and rubber compounds, which are difficult for single-energy systems to find. However, some materials remain challenging.

Hard plastics are typically detectable at sizes of 2-5mm or larger.

Soft plastics may require pieces of 8mm or more.

Thin plastic films often go undetected.

Contaminants can enter the food supply chain from various sources, from the field to the factory. Machinery parts are a common source of metal fragments, while glass can originate from broken jars or light fixtures.

| Contaminant | Common Sources |

|---|---|

| Metal | Machinery (blades, screws, wire), employee jewelry |

| Glass | Bottles, jars, light fixtures, gauge covers |

| Stone | Fields (pebbles, grit), building materials |

| Bone | Calcified fragments from raw animal products |

Beyond finding foreign objects, a modern food electronics x ray machine serves as a powerful quality assurance tool. It performs several automated checks in a single pass.

Mass Measurement: The system verifies that each package meets its specified weight, rejecting any that are over or under the defined tolerance.

Fill-Level Verification: It inspects containers to ensure they are filled to the correct level, providing feedback to fillers to prevent waste.

Component Integrity: The system can count items within a package, confirming that a variety pack has all its components or that no products are broken or missing.

The use of X-rays naturally raises questions about safety for both the food product and the machine operators. Manufacturers design food electronics x ray machines with multiple layers of protection, adhering to strict international standards. The technology is overwhelmingly safe, posing no risk to food quality or personnel when used correctly.

A common misconception equates X-ray inspection with food irradiation, but the two processes are vastly different. Food irradiation uses high doses of radiation to preserve food and kill bacteria. X-ray inspection, in contrast, uses an exceptionally low dose for a very brief period.

The radiation dose a food product receives during inspection is typically 1 millirad or less. To put this in perspective, the Gray (Gy) is the standard unit for radiation dose, with 1 rad equaling 0.01 Gy. Government regulations permit an absorbed dose of up to 10 Grays for inspection, a level far above what systems actually use.

The U.S. Food and Drug Administration (FDA) strictly regulates these systems under 21 CFR 1020.40. This regulation requires cabinet X-ray systems to emit less than 0.5 milliroentgen per hour at a distance of five centimeters from any external surface. Modern machines operate well below this limit.

The dose from an inspection system is minuscule compared to other sources. The average person's annual exposure to natural and man-made background radiation is about 360 mRem. This amount significantly exceeds the exposure from a properly maintained food X-ray machine. Furthermore, the World Health Organization (WHO) has confirmed that radiation levels up to 10,000 Gy—a dose ten million times higher than that used in inspection—do not impact food safety.

The extremely low radiation dose and brief exposure time ensure that X-ray inspection has no measurable effect on food products. Extensive testing and decades of commercial use confirm that the technology preserves the sensory and nutritional qualities of food.

Scientific evidence consistently shows that taste, texture, and nutritional value remain unchanged. Customers of brands using X-ray inspection report no difference in flavor or consistency. The brief exposure generates no heat and causes no chemical or molecular changes. Vitamins, minerals, proteins, and fats pass through the inspection process completely unaffected. In fact, research confirms that the nutritional profile of an X-rayed product is indistinguishable from a non-inspected one. Even organic foods retain their certification status after inspection.

While some studies show that very high-dose irradiation (e.g., 4-6 kGy) can reduce levels of certain vitamins like B1 and C, these doses are millions of times greater than those used for contaminant detection. The WHO confirms that food remains safe and nutritionally complete at levels far exceeding those in an inspection system, making any comparison to high-dose irradiation irrelevant.

Protecting operators is a paramount design consideration for every food electronics x ray machine. These systems are fully enclosed cabinets built with robust engineering controls that make them exceptionally safe. Key safety features include:

Physical Shielding: The machine's main body is constructed from thick steel. The entry and exit points of the conveyor feature lead-lined or lead-free curtains made from dense, mixed-metal blends. These materials effectively contain the low-level X-rays inside the cabinet.

Safety Interlocks: Every access panel and door is equipped with a safety interlock. This device automatically cuts power to the X-ray generator if a door or panel is opened during operation. This critical feature makes it impossible for an operator to be accidentally exposed to an active X-ray beam.

Warning Lights: The system provides clear visual cues about its operational status. An easily visible, fail-safe warning light labeled 'X-RAY-ON' illuminates only when the X-ray tube is energized. Additional lights indicate when the shutter is open, providing another layer of operational awareness.

Emergency Stops: Prominently placed emergency stop buttons allow operators to immediately shut down the entire system, including the X-ray generator and conveyor, in any unforeseen situation.

These engineering controls are supplemented by administrative procedures, including clear signage and comprehensive operator training. Regular inspection and testing of all safety systems by a qualified expert ensure the machine remains compliant and safe throughout its operational life.

X-ray food inspection is a crucial and safe technology for modern food safety standards. It relies on the fundamental physics of differential absorption to non-destructively "see" inside food products. This capability allows manufacturers to detect a wide array of physical contaminants, protecting consumer health and brand reputation.

For example, the Stephano Group successfully implemented an X-ray system to enhance its safety measures, providing an additional layer of protection beyond what metal detectors could offer.

The technology achieves this without altering the food's quality, taste, or nutritional value.

No. The technology uses very low energy. It passes through food without changing its molecular structure, leaving no radiation behind. The food remains completely safe for consumption.

The technology struggles with low-density materials. It typically cannot detect contaminants like hair, wood, cardboard, or thin plastic films because their density is too similar to the food.

Detection capability depends on the system and product. High-performance machines can find dense contaminants like metal spheres as small as 0.4 mm under optimal inspection conditions.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Ultra-fine contaminants detection, UHD X-Ray detec...

Glass-in-glass / Metal-in-metal inspection, small ...

Recommedation: Chili, walnut, peanuts, soybeans, c...

Recommedation: Small particle, flat products such...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

X-ray inspection machines have become indispensabl...

MoreAs pet owners increasingly view their companions a...

MoreConsumers and manufacturers alike worry about cont...

MoreAdvanced nut sorting machine technology combines H...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Control ManagerThis food X-ray machine has revolutionized our contamination detection process. The clarity and accuracy are outstanding, significantly reducing false rejects while ensuring product safety.

Sarah Chen

Food Safety TechnicianHighly reliable machine for detecting metal, glass and plastic contaminants. The user interface is intuitive and the maintenance requirements are minimal. Great investment for any food processing facility.

David Thompson

Production SupervisorOutstanding performance in detecting foreign materials in our packaged meals. The automated rejection system works flawlessly and has helped us maintain our quality standards consistently.

Jennifer Williams

Plant ManagerExcellent detection capabilities for various contaminants. The machine integrates well with our existing production line and the technical support team is very responsive when needed.