Principle of X-ray Inspection Machines in the Food Industry

X-ray inspection machines have become indispensabl...

More

You must first define your main inspection goals. The right food smt x ray machine balances strong detection with smooth operations. This checklist helps you understand technical details. It also guides you through financial choices, making your decision easier and more effective for your business's safety standards.

The first step in choosing the right system is to analyze your product and the risks associated with it. A clear understanding here will guide all your technical decisions.

You must evaluate your product's physical properties. A product's density, thickness, and temperature directly impact inspection accuracy. Denser or thicker items absorb more X-rays, which is the basis for detection. Unlike other systems, an X-ray machine's sensitivity is not affected by moisture or salt content.

Note: For frozen food production, low temperatures can affect a machine's performance. You should look for systems with cold-resistant components and insulated tunnels to ensure stable operation and prevent issues from frost or condensation.

Next, you need to identify the foreign materials most likely to appear in your product. Different food categories face different risks. For example:

Processed Meats: Plastic is a very common contaminant.

Baked Goods: Metal fragments and plastic pieces are frequent concerns.

Dairy: Wood splinters have been found in products like ice cream.

Knowing these risks helps you configure your inspection goals.

You must determine the smallest contaminant size your system needs to find. The FDA does not set a universal standard. Instead, you must establish your own critical limits through a hazard analysis. A quality food smt x ray machine can detect dense materials like metal, glass, stone, and certain dense plastics.

Finally, consider your packaging. Many inspection systems struggle with foil or metallized film. However, X-ray technology can see through these materials with no major impact on detection levels. This capability ensures you can find contaminants even in challenging packaging formats.

After analyzing your product, you must evaluate how a food smt x ray machine will fit into your daily operations. A system is only effective if it works seamlessly within your existing production environment.

Your new machine must keep up with your production line. You need to match the system’s inspection speed to your line’s output. Modern single-energy systems can reach speeds of up to 400 feet per minute. Some machines process over 500 units per hour. For high-volume needs, dual-lane systems can inspect more than 120 pieces per minute in each lane, doubling your throughput.

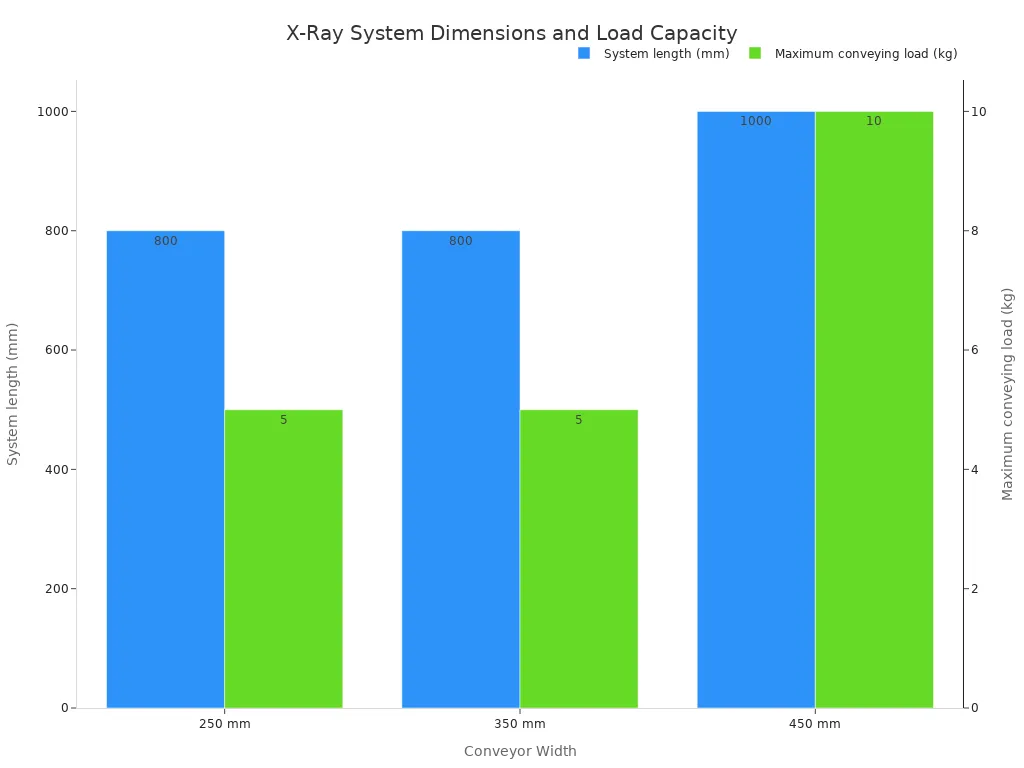

You must measure the available space on your production floor. X-ray systems come in various sizes. Some compact models are only 1000mm long, making them ideal for tight spaces. Larger systems require more room. Consider the machine's dimensions and how they fit your line's layout.

Proper integration includes choosing the right rejection mechanism. This device removes contaminated products from the line automatically. Your choice depends on your product type.

Air-Blast Reject: Uses a puff of air. It works best for lightweight items like snack bags.

Pusher Reject: A mechanical arm pushes heavier products like meat trays off the line.

Drop Flap Reject: A flap opens to remove contaminated bulk products like grains or powders.

Your plant's environment can affect the machine's performance. You should check the system’s required operating conditions for temperature and humidity. Most systems function well in a wide range of environments.

Tip: Look for a machine rated to operate in temperatures from -10°C to 40°C (14°F to 104°F) and in humidity levels between 30% and 90%. This ensures reliable performance in most food production facilities.

Your new X-ray system must meet strict industry rules. You need to verify its compliance and safety features to protect your brand and your customers. This step ensures your investment aligns with legal and quality assurance requirements.

You must ensure your machine helps you comply with food safety laws. The FDA’s Food Safety Modernization Act (FSMA) is a key regulation. It requires you to identify and control potential dangers.

FSMA mandates the identification of physical hazards like stones, glass, and metal. Your facility must evaluate these risks. You must then implement preventive controls to minimize or prevent them.

Standards like HARPC and Global Food Safety Initiative (GFSI) schemes also guide this process. For example, SQF Edition 9 specifically calls for technologies like X-ray inspection to remove foreign matter.

Modern X-ray systems are extremely safe. Radiation leakage is minimal, often at 1 μSv/h or less. This is well below the maximum level of 5 μSv per hour allowed by U.S. regulations. Manufacturers must follow federal rules like FDA 21 CFR 1020.40. They must provide you with:

Instructions for radiological safety procedures.

A schedule of required maintenance.

Technical ratings for the X-ray equipment.

The machine's durability depends on its IP rating. This rating tells you how well the equipment is sealed against dust and water. You should choose a rating that matches your plant's cleaning procedures.

| IP Rating | Protection Against Solids | Protection Against Liquids |

|---|---|---|

| IP65 | Total dust protection | Low-pressure water jets |

| IP66 | Total dust protection | High-pressure water jets |

| IP69K | Total dust protection | High-pressure, high-temperature spray |

An IP69K rating is best for harsh environments. It allows for intense, high-temperature washdowns without damaging the machine.

A modern food smt x ray machine should offer robust data features. FSMA requires you to monitor and verify your preventive controls. Your system should automatically log images and data for every rejected product. This creates a clear record for traceability. It also helps you identify patterns in contamination, improving your overall process.

The physical machine is only half of the equation. You must also assess the software that powers it. Modern software enhances detection, simplifies operation, and provides critical data for your food safety program.

Your team needs software that is easy to learn and operate. An intuitive, Windows-based interface reduces training time and simplifies daily tasks. Look for systems with an auto-learn function. This feature simplifies product setup and changeovers. Advanced software can also automatically detect package edges and set the optimal X-ray power. These features ensure maximum detection accuracy without needing an expert operator.

Today’s X-ray systems offer more than just contaminant detection. Many now use artificial intelligence (AI) to improve performance. AI can boost the detection of low-density objects and reduce false rejects by up to 20%. Beyond AI, you should look for other valuable inspection capabilities:

Mass Measurement: Checks product weight.

Component Counting: Ensures all items are in the package.

Fill Level Verification: Confirms correct product volume.

Integrity Checks: Finds damaged products or packaging.

Your X-ray machine must provide robust data for traceability and audits. The system should automatically log images and results for every rejected product. Each record needs a timestamp, batch number, and operator ID. This data creates a clear, tamper-proof record for compliance. You can use these reports to track contamination trends and prove your preventive controls are working effectively.

Even the best system requires well-trained operators. You should plan for comprehensive training that covers key topics.

Essential Training Topics:

Radiation safety procedures

Basic machine operation and calibration

Software navigation and product setup

Simple maintenance and troubleshooting

Proper training ensures your team can operate the machine safely and efficiently, maximizing your return on investment.

Choosing the right vendor is as important as choosing the right machine. You need a partner who offers strong support and transparent pricing. This final step helps you evaluate the financial and service aspects of your purchase.

You should look beyond the initial purchase price. The total cost of ownership (TCO) gives you a truer picture of the long-term investment.

The initial price often makes up only 20-30% of the total cost over a decade. The rest comes from hidden expenses.

Consider these key factors that contribute to TCO:

Running Costs: This includes power, air, and water usage.

Service and Parts: This covers maintenance, software updates, and training.

Performance: This relates to accuracy, reliability, and uptime.

Ease of Use: This impacts labor hours for operation and cleaning.

A good vendor provides more than just a machine. You should compare their support and service agreements. Ask about preventive maintenance schedules, software update policies, and operator training programs. A strong service plan ensures your equipment runs efficiently and minimizes downtime.

You should always request a live demonstration. A demo lets you test the machine with your actual products. It also helps you calculate the potential return on investment (ROI).

Preventing just one recall could pay for the equipment in as little as five days.

Even without a recall, savings from reduced product giveaway can lead to an ROI in about two years.

Finally, you must review the warranty. A comprehensive warranty protects your investment. Look for vendors offering at least a 2-year warranty that covers all parts and components. You should also confirm the availability of spare parts. Quick access to parts is essential for keeping your production line moving.

Your successful purchase depends on a full evaluation of your product, operations, and vendor partnership. You make an informed choice to protect your brand and ensure consumer safety. The right food smt x ray machine provides a strong return on investment and is a key asset for modern food safety.

Yes. X-ray inspection does not make food radioactive. The energy levels are very low. Your food products remain completely safe for consumers to eat.

No. Modern machines have excellent shielding and safety interlocks. Radiation levels are extremely low. Your operators do not need any special protective gear for daily operation.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Glass-in-glass / Metal-in-metal inspection, small ...

Automatic recognition and rejection, fish bone ins...

Conventional and unconventional contaminant detect...

Recommedation: Small particle, flat products such...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

X-ray inspection machines have become indispensabl...

MoreAs pet owners increasingly view their companions a...

MoreConsumers and manufacturers alike worry about cont...

MoreAdvanced nut sorting machine technology combines H...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Jennifer Martinez

Quality Control ManagerThe food SMT X-ray machine has revolutionized our quality control process. Detection accuracy for metal contaminants is exceptional, and the automated rejection system integrates perfectly with our production line.

David Chen

Production SupervisorExcellent machine for foreign object detection in our snack products. The image clarity helps us identify even the smallest contaminants. Setup was straightforward and the interface is user-friendly.

Sarah Johnson

Food Safety SpecialistThis X-ray inspection system has significantly improved our food safety compliance. The sensitivity settings allow us to detect various contaminants while minimizing false rejects. Technical support has been responsive and knowledgeable.

Michael Thompson

Plant ManagerOutstanding performance in detecting foreign materials in our baked goods. The machine's durability and low maintenance requirements have made it a valuable asset to our production facility. Highly recommended for food manufacturers.