Meat Packaging Revolution: Mastering Detection Challenges with Next-Gen X-ray and Vision Systems

This article delves into the persistent pain point...

More

Food x ray detection systems are vital quality control tools. They use advanced technology to find physical contaminants during food production. Foreign material poses a significant industry risk, causing 71 recalls in 2023. This technology is essential for ensuring product safety and protecting brand reputation. The market reflects this importance.

| Metric | 2023 Value | 2032 Value | CAGR (2024-2032) |

|---|---|---|---|

| Market Size | US$ 1,528.8 million | US$ 2,904.1 million | 7.39% |

Food x ray detection systems operate on the principle of density. They pass a beam of energy through a product to a detector, creating a grayscale image of the product's interior. Denser materials absorb more X-ray energy, allowing the system to "see" what is inside.

Every system relies on three key parts working together.

X-ray Generator: This component produces a controlled X-ray beam. It applies high voltage to a tube, generating electrons that strike a metal target. This action emits a stream of X-rays, which are then focused into a fan-shaped beam that scans the product.

Detector: Positioned opposite the generator, the detector captures the X-rays that pass through the product. It converts this X-ray energy into an electrical signal, which is then sent to the system's computer for processing.

Software: This is the brain of the operation. Advanced algorithms analyze the electrical signals from the detector to construct and interpret the product's image.

The inspection process is a rapid, automated scan. As a product travels along a conveyor, it passes through the X-ray beam. The detector measures the amount of X-ray energy that reaches it at every point. Materials with higher density, like a piece of metal, absorb more energy than the surrounding food. This difference in absorption creates a digital image. Each pixel in the image is assigned a grayscale value based on the energy detected, forming a detailed density map of the product.

The system's software analyzes the grayscale image to find anomalies. A contaminant's higher density causes it to appear as a darker or lighter spot compared to the uniform food product.

Advanced software uses powerful algorithms to analyze these subtle differences in contrast. With a grayscale range of up to 65,535 values, the software can differentiate contaminants from the product with incredible precision. This allows the system to automatically identify foreign objects like glass, stone, or metal and trigger a rejection mechanism, ensuring the contaminated product never reaches the consumer.

X-ray inspection systems identify foreign objects by detecting differences in density. Their capabilities extend far beyond finding a simple piece of metal, making them a versatile tool for comprehensive quality assurance.

These systems excel at finding a wide range of dense contaminants. X-ray inspection can detect all metal types, including ferrous, non-ferrous, and even stainless steel fragments as small as 1.5mm. It also reliably identifies other common physical hazards like glass shards and mineral stones.

Detecting calcified bone fragments in poultry presents a unique challenge. Manual inspection is often unreliable, and traditional X-rays can miss up to 30% of fragments. Modern solutions address this issue effectively.

Advanced systems now combine X-ray with other imaging technologies. They can detect bone fragments down to 1 mm with 99% reliability and a false positive rate below 3%. This significantly reduces the risk of consumer injury and product recalls.

Not all plastics are visible to X-ray technology. The key factor is density. Plastics with a density close to water, such as HDPE and UHMW, are difficult to detect. However, food x ray detection systems can identify several types of high-density plastics that may enter the production line from worn machinery components. Detectable plastics include:

PTFE (Teflon)

Viton

Acetal

Sustarin C®

Modern X-ray systems offer much more than just contaminant detection. They perform several simultaneous quality checks on the same pass, adding significant value to the production line. These capabilities allow manufacturers to monitor product integrity and consistency in real time. Some of these added checks include:

Verifying correct fill levels

Identifying missing components or items

Checking for damaged products or packaging

Measuring mass and estimating portion size

Choosing the right inspection technology depends on the product and potential contaminants. Manufacturers can select from several types of food x ray detection systems, each designed for specific applications and product characteristics.

Single-energy systems are the most common type of X-ray inspection. They are highly effective for products with a uniform texture and density. These systems excel at inspecting both unpacked foods and products in various packaging formats.

Typical Applications: Yogurt, butter, meat, poultry, and baby food.

Detectable Contaminants: Ferrous and non-ferrous metals, stainless steel, glass, mineral stone, and calcified bone.

Packaging: Inspects products in ceramic containers, metal cans, carton boxes, plastic trays, and bags.

Note: While powerful, these systems have limitations. They cannot reliably detect low-density foreign bodies like hair, wood, insects, or plastics made only of hydrocarbons (e.g., PP, PA, PC).

Dual-Energy X-ray Absorptiometry (DEXA) technology offers a more advanced solution for complex products. It analyzes a material's average atomic number instead of just its density. This method allows the system to differentiate between organic and inorganic materials, which is ideal for inspecting products with "busy images" like salad mixes, cereals, or trail mixes. DEXA generates two separate images at different energy levels, enabling algorithms to identify foreign bodies with greater precision.

Some products require specialized inspection equipment due to their shape, size, or handling process. Application-specific systems are engineered to meet these unique challenges.

Side-View Systems: These are designed for upright containers like cans, jars, and bottles. They scan dense regions near the bottom or top that top-down systems might miss.

Bulk-Flow Systems: This equipment inspects raw, unpackaged materials such as nuts, seeds, grains, or frozen berries. It removes contaminants early, protecting downstream machinery.

Pipeline Systems: These systems inspect pumped products like sauces, slurries, and processed meats. They provide crucial, non-destructive contaminant detection within the processing line.

Selecting the right X-ray inspection system is a critical decision that impacts product safety, operational efficiency, and brand integrity. A thorough evaluation of several key factors ensures a manufacturer invests in a solution that meets their specific needs for 2026 and beyond. This process involves a deep dive into the product, potential risks, production environment, and compliance landscape.

The physical properties of a food product are the primary determinant of which X-ray system will perform best. Manufacturers must assess their product's size, shape, texture, and density. A homogeneous product like a block of cheese has a uniform density, making it ideal for a standard single-energy system. In contrast, a bag of trail mix contains items of varying densities, creating a "busy" image that requires a more advanced dual-energy system to accurately distinguish contaminants from the product itself. The system must also accommodate the product's physical dimensions, whether it is a small yogurt cup or a large case of finished goods.

A comprehensive risk assessment helps pinpoint the most probable foreign materials that could enter the production line. This analysis should be a core component of a facility's Hazard Analysis and Critical Control Points (HACCP) plan. A HACCP plan systematically identifies biological, chemical, and physical hazards. For physical hazards, it establishes critical control points where contamination is most likely to occur.

Common sources of physical contaminants vary widely:

Raw Materials: Fields and farms can introduce stones, glass, or sand during harvesting.

Equipment: Machinery can shed metal fragments, nuts, bolts, or pieces of mesh screens during processing.

Food Handlers: Employees can accidentally introduce items like jewelry, pen caps, or hair.

Packaging: Materials such as plastic wrap, wood chips, or glass can break off and enter the food.

Pests: Animals may contribute hair, feathers, or droppings.

By understanding these sources, a manufacturer can tailor their detection strategy. For example, if the primary risk is metal fragments from machinery, the HACCP plan might mandate both regular equipment inspections and the use of an X-ray system after packaging as a final control measure.

The material used for packaging significantly influences the effectiveness of food x ray detection systems. Different materials interact with X-rays in unique ways, and the system must be calibrated to account for them.

Unlike traditional metal detectors, X-ray systems are not affected by metalized film. This packaging has a very low absorbance value, allowing the system to "see through" it and maintain high sensitivity for detecting metal contaminants inside.

Other packaging types present different challenges:

Metal Cans: These medium-density containers require software that can interpret the can's own features—like its shape, ribs, and pull-tabs—to avoid misidentifying them as foreign objects.

Glass Jars: Detecting glass fragments within a glass container is difficult. Advanced X-ray systems often inspect jars twice: once when empty to find defects and again after filling to identify contaminants introduced during processing.

An X-ray system must integrate seamlessly into an existing production line without creating a bottleneck. Manufacturers need to measure their line speed, typically in feet per minute or products per minute, to select a system capable of matching that throughput. The physical footprint is another crucial consideration. Production facilities often have limited floor space, so the chosen system must fit within the available area. This includes accounting for the main inspection unit, the rejection mechanism, and any necessary conveyor modifications.

Adherence to food safety regulations is non-negotiable. Government bodies and major retailers set strict standards for physical contaminant control. A manufacturer's chosen system must meet these requirements to maintain market access.

| Regulatory Body | Key Requirements for Physical Hazards |

|---|---|

| USDA & FDA | Both require documented procedures for handling foreign materials and the use of detection equipment. The FDA also sets "Action Levels" for certain defects. |

| GFSI Standards | Mandate documented policies and the use of detection equipment for a broad list of foreign materials, including metal, glass, plastic, and ceramics. |

Beyond government regulations, many large retailers impose their own stringent requirements. For instance, Costco mandates that most of its food suppliers install a properly calibrated X-ray detection device for finished products. Suppliers may receive an exemption only under specific circumstances, such as when product characteristics limit X-ray performance or when an appropriately sized physical barrier like a sieve is already in place. Failure to comply can result in automatically failing an audit, jeopardizing a crucial business relationship.

Artificial intelligence (AI) is transforming food x ray detection systems from simple scanners into intelligent quality assurance partners. By 2026, integrating AI will be a standard for manufacturers seeking to maximize safety and efficiency. AI algorithms learn from vast datasets of images, enabling them to identify contaminants with greater precision and unlock new operational insights.

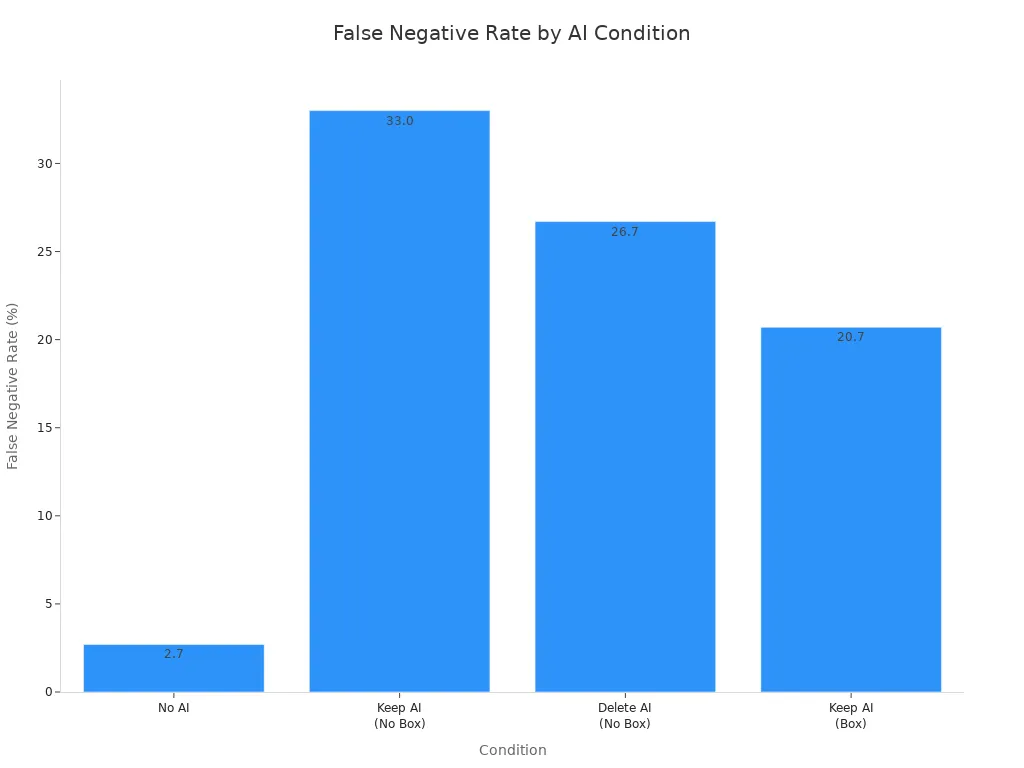

AI-powered systems significantly enhance inspection capabilities. Automated inspection can reduce contamination errors by up to 70% compared to manual methods. These smart systems learn to distinguish between actual contaminants and normal product variations, such as air bubbles in cheese or fruit pieces in yogurt. This learning process helps lower the false reject rate, saving valuable product from being wasted. However, proper implementation is key. As the data shows, an improperly configured AI can perform worse than a system with no AI at all, underscoring the need for expert setup.

AI also plays a crucial role in maintaining the system itself, preventing costly downtime.

AI will not only enhance defect detection but also play a vital role in predictive maintenance. Self-learning X-Ray inspection machines will be able to diagnose system performance issues and anticipate maintenance needs, reducing downtime and improving reliability.

These systems continuously monitor their own health by tracking key metrics. AI analyzes the distribution of risk scores, model firing rates, and other outputs to detect any performance drift. This allows maintenance teams to address potential component failures before they happen. This allows maintenance teams to address potential component failures before they happen.

The data collected by an AI-powered X-ray system offers a wealth of information for process optimization. Quality managers can analyze X-ray images and production reports to improve traceability and make faster, more accurate decisions. This data helps them pinpoint the source of recurring contaminants, enabling them to adjust upstream equipment settings. By leveraging these insights, manufacturers can optimize production lines, reduce food waste, and strengthen overall product safety.

Selecting the right X-ray system requires a manufacturer to thoroughly analyze their product, potential risks, and production environment.

This investment is a strategic move. It enhances food safety, guarantees quality, and protects a brand's reputation in a competitive market, ensuring long-term success and consumer trust. This investment is a strategic move. It enhances food safety, guarantees quality, and protects a brand's reputation in a competitive market, ensuring long-term success and consumer trust.

Yes, the process is completely safe. The radiation dose is extremely low and does not make food radioactive. The food's safety and quality remain unaffected after inspection.

Metal detectors only find metallic contaminants. X-ray systems offer broader protection. They detect metal, glass, stone, bone, and high-density plastics, providing more comprehensive inspection capabilities.

No, they do not. The energy used is minimal. Extensive studies confirm that X-ray inspection has no impact on a food product's flavor, texture, or nutritional value.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Recommedation: Rice, wheat, corn, grain, pulses, s...

Automatic recognition and rejection, fish bone ins...

Conventional and unconventional contaminant detect...

Recommedation: Aquatic products, pet food, candy, ...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

This article delves into the persistent pain point...

MoreAdvanced nut sorting machine technology combines H...

MoreIn the fast-paced world of food production, ensuri...

MoreAs pet owners increasingly view their companions a...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Assurance ManagerThese food x-ray detection systems have revolutionized our quality control process. The precision in detecting foreign objects like metal fragments and glass shards is remarkable. Our product safety has improved significantly since installation.

Sarah Chen

Production SupervisorExcellent detection capability for bone fragments in our poultry products. The system integrates well with our existing production line and requires minimal maintenance. The false rejection rate is impressively low compared to previous systems we've used.

David Thompson

Food Safety DirectorOutstanding performance in detecting contaminants in our baked goods. The system's sensitivity settings are highly customizable, allowing us to maintain quality without compromising production speed. The technical support team is responsive and knowledgeable.

Jennifer Williams

Operations ManagerHighly reliable system for our canned food production. The x-ray technology effectively identifies density variations and ensures every can meets our safety standards. The user interface is intuitive and our operators were trained quickly.