Introduction to RaymanTech Optical Sorters for Farm Products and Food Processors

RaymanTech, as a leading provider of inspection an...

More

The seafood industry is advancing rapidly. The global seafood processing equipment market is projected to reach USD 3.04 billion by 2033, driving major innovation. Processors now utilize AI vision, hyperspectral imaging, and advanced robotics. These technologies, including the frozen seafood optical sorter, are setting new standards for quality and efficiency.

AI-powered vision systems are revolutionizing seafood processing. They deliver a new level of speed and accuracy that manual sorting cannot match. These intelligent platforms use advanced imaging to make split-second decisions, improving both quality and throughput on the processing line.

Modern sorting robots use high-speed cameras and sophisticated deep learning algorithms. These systems train on massive datasets containing thousands of images of different fish species, sizes, and quality grades. During operation, the AI analyzes each fish passing on the conveyor belt. It instantly identifies the species, measures its size, and assesses its grade. This process allows for sorting thousands of individual fish or fillets per minute with incredible precision, far exceeding human capabilities.

These vision systems do more than just sort; they generate a constant stream of valuable data. The systems collect and analyze millions of datapoints daily, giving managers instant feedback to optimize production. This data provides precise biomass estimates, as highlighted by a manager at one of the world's largest seafood companies.

“The Tidal system gives us under 3% error in biomass estimates at harvest time. We are able to know exactly what to expect when we harvest a pen. We can optimize which pens to harvest and when to fill which customer orders.” – Regional Production Manager, Mowi ASA

The benefits of this real-time monitoring are significant:

Accurate live weight trends with near 98% accuracy.

Detailed biomass distribution for optimized harvest scheduling.

Proactive management of yield quality risk.

Reliable monitoring of health problems for early intervention.

A case study with ThisFish Inc. further demonstrates this impact. Their AI model analyzed tuna cannery data and found that factors like cold storage duration could alter yield by up to three percent, proving a direct link between data analytics and profitability.

While standard cameras see in three colors (red, green, and blue), hyperspectral imaging (HSI) captures information across hundreds of spectral bands. This technology allows sorting systems to analyze the chemical composition of seafood, revealing quality attributes invisible to the naked eye. It provides a deep, non-invasive look inside each product on the line.

HSI technology is a powerful tool for ensuring seafood safety and quality. It rapidly assesses key freshness indicators like Total Volatile Basic Nitrogen (TVB-N) and can even combine multiple metrics into a Comprehensive Freshness Index (CFI) for a more holistic evaluation. This gives processors an objective measure of product shelf life.

The technology also excels at identifying hidden hazards. For parasite detection, HSI is significantly more effective than traditional methods. Its ability to scan beneath the surface of a fillet makes it ideal for finding embedded nematodes like Anisakis.

| Method | Parasite Detection Rate |

|---|---|

| Hyperspectral Imaging (HSI) | 73% |

| Manual Inspection (Candling) | 50% |

This capability allows processors to identify and remove contaminants in real-time on industrial lines, drastically reducing risks and improving final product safety.

Fat and moisture content are critical indicators of seafood's flavor, texture, and nutritional value. HSI systems perform this analysis non-invasively with remarkable precision, achieving prediction accuracies above 96% for both fat and moisture in salmon fillets. This automated analysis provides immediate, actionable data that transforms quality control.

The benefits for modern processors are substantial:

Real-time Analysis: Processors can make instant decisions to sort products based on specific quality grades.

Improved Efficiency: Automated sorting minimizes waste and optimizes the use of raw materials.

Enhanced Product Value: Consistent quality control allows producers to meet specific market demands and differentiate their products.

Greater Profitability: Optimized processes and higher-quality products lead to better market prices and improved economic returns.

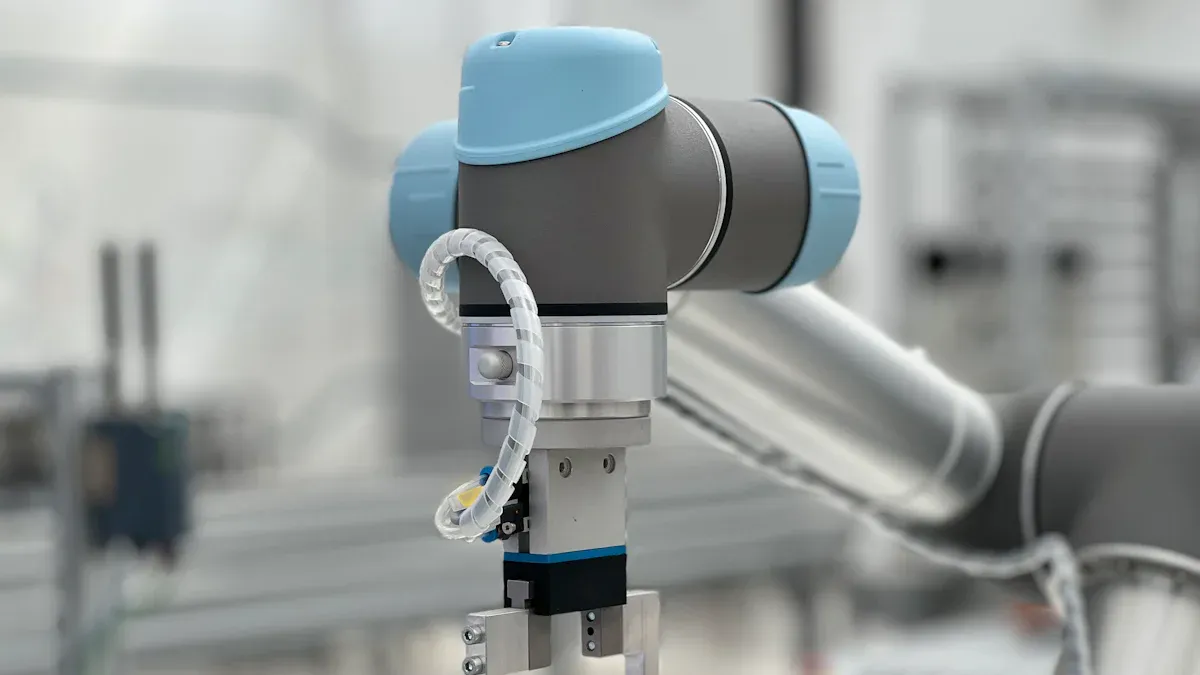

Robotic systems are the physical backbone of the modern sorting line. They execute the complex decisions made by AI and imaging technologies. The latest advancements focus on two critical goals: handling delicate seafood with extreme care and maximizing the speed of the entire operation. These robots combine strength, speed, and a surprisingly gentle touch.

Seafood products like fish fillets and scallops are fragile and easily damaged. Traditional rigid grippers often bruise or break them, leading to yield loss. Soft robotics provides an elegant solution. These grippers, made from flexible materials, can conform to the shape of an item and apply just enough pressure to lift it securely.

Recent innovations have made these grippers incredibly versatile.

Kirigami-inspired designs can gently pick up a single water drop yet also hold over 14 pounds.

AI and 3D imaging inform the gripper how to handle different products, allowing a system to pick over 70 items per minute.

Adaptive grippers with machine learning automatically apply the correct force for different products, achieving high accuracy.

This technology allows processors to handle delicate items at high speeds without sacrificing quality.

Collaborative robots, or "cobots," are designed to work safely alongside human employees. They augment human capabilities, taking over repetitive sorting tasks while people handle more complex quality checks. This human-robot collaboration boosts efficiency and creates a safer work environment.

Safety is the central principle of cobot integration. Industry standards like ISO 10218 define the requirements for safe operation.

Safety depends on how the robot is used, not just the robot itself. The focus is on creating safe "collaborative applications."

Processors achieve this through several key features. Power and Force Limiting (PFL) technology ensures any contact between a robot and a person remains below harmful thresholds. Speed and separation monitoring systems use sensors to slow or stop the robot when a person gets too close. These safeguards allow cobots to become valuable, trusted partners on the processing floor.

Beyond general sorting, specialized robotic systems are emerging to tackle unique challenges within high-value species like salmon and crab. These innovations provide targeted solutions that dramatically improve efficiency, sustainability, and profitability for specific sectors of the seafood industry.

Hatcheries can now optimize salmon production by sorting smolt based on gender. Automated systems use AI and advanced imaging to identify the sex of juvenile salmon with incredible accuracy, far surpassing human capabilities.

| Method | Success Rate |

|---|---|

| Automated AI | >99% |

| Manual Inspection | 90-95% |

This technology allows for separate male and female populations. Processors can then tailor feeding, lighting, and harvest schedules to each group's unique growth patterns. Males mature faster, while all-female groups grow larger. This separation increases efficiency by over 20% and can boost margins by 15%. As Erling Aspen, general manager at a leading aquaculture firm, noted, "Fish in sex-separated cages grow faster, have lower mortality and fewer wounds."

Manual crab sorting is slow and prone to error. New biometric systems use 3D scanning and AI to automate this process. A device like the CrabScan360 captures a crab's unique biological features, or "fingerprints," from its carapace. The AI then analyzes this data to instantly determine species, sex, and size. This allows processors to rapidly sort large volumes with precision.

The benefits of this technology extend to full supply chain traceability.

It overcomes the limitations of physical tags, which are easily lost or damaged.

It enables accurate identification without a label, enhancing food security.

It helps verify product authenticity and prevent counterfeit products from entering the market.

This automated data collection ensures regulatory compliance and provides processors with unparalleled control over quality and inventory.

Sorting frozen seafood presents unique challenges due to its rigid, often irregular shapes and harsh processing environment. The frozen seafood optical sorter is a game-changing technology designed specifically for this task. It combines advanced imaging with robust automation to handle frozen blocks and individual quick-frozen (IQF) products with precision and speed. This technology is rapidly becoming essential for large-scale frozen seafood operations.

A modern frozen seafood optical sorter uses sophisticated 3D sensor technology to analyze products on the line. As frozen fish blocks or fillets pass through the system, high-resolution cameras and lasers scan each item from multiple angles. This process creates a detailed 3D model in real-time. The system’s software then analyzes this model to determine volume, weight, and dimensional accuracy. Based on this data, the machine directs pneumatic ejectors or robotic arms to sort the products into designated grades or batches, ensuring uniformity and adherence to specifications.

Automated sorting delivers significant advantages over manual methods, which are slow and inconsistent in cold environments. A frozen seafood optical sorter enhances operations by improving both product quality and worker safety.

Key operational benefits include:

Enhanced Efficiency: Automation achieves high throughput rates, saving labor costs and preserving product condition.

Improved Consistency: The system eliminates human subjectivity, ensuring uniform product quality and standardized portions.

Reduced Waste: Precise sorting greatly reduces misclassification and minimizes product downgrades.

Traceability: The technology captures valuable data on every block, enabling full traceability for quality control.

Automation also creates a safer workplace. Robotic systems take over the heavy lifting and repetitive motions in extreme cold, preventing back strain and repetitive stress injuries. This removes employees from hazardous, sub-zero environments, drastically reducing health and safety risks.

The future of seafood processing is not about individual technologies but their complete integration. The smart sorting line of 2025 combines AI, advanced imaging, and robotics into a single, cohesive ecosystem. This unified system acts as the digital nervous system of the processing floor, where every component communicates to optimize the entire workflow from start to finish.

An integrated line fuses the distinct capabilities of modern automation. Hyperspectral cameras first scan each product, gathering data on quality, freshness, and potential defects. This information feeds directly into an AI brain, which instantly analyzes it and makes a sorting decision. Finally, soft robotic grippers execute the command, gently moving the product to its correct destination. This seamless data flow from imaging to decision to action eliminates delays and maximizes efficiency. The system monitors critical control points, such as temperature and pH levels, ensuring consistent quality and safety without human intervention.

This integrated approach delivers transformative benefits. Automation provides a rapid return on investment (ROI), with many processors seeing a full return in 12 to 18 months. One Asian seafood plant provides a compelling example:

Achieved a full ROI in under 5 months.

Increased production yield by 28%.

Reduced quality assurance complaints by 60%.

Beyond financial gains, integration enhances food safety and traceability. Technologies like AI and blockchain create a transparent supply chain, allowing for real-time monitoring and rapid issue detection. Automated systems excel at identifying foreign objects and verifying product weight, removing contaminated or substandard items before they reach packaging. This level of control minimizes human error, ensures regulatory compliance, and builds consumer trust.

AI vision, hyperspectral imaging, and soft robotics are revolutionizing seafood sorting. These technologies deliver unparalleled accuracy and efficiency, boosting profitability and setting new safety standards.

Adopting robotic systems, including the frozen seafood optical sorter, is no longer a future concept. It is a critical competitive advantage for processors today.

The main innovations are AI vision, hyperspectral imaging, and soft robotics. They deliver superior accuracy, speed, and gentle handling, boosting efficiency and product quality.

Advanced systems use soft robotic grippers. These grippers mimic the human touch, conforming to the product's shape to handle delicate items without causing damage or yield loss.

Yes, it is a strategic investment. Automation provides a rapid return by:

Increasing production yield

Reducing long-term labor costs

Minimizing product waste

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Recommedation: Small particle, flat products such...

Recommedation: Aquatic products, pet food, candy, ...

Uneven and overlapped product detection, thin & lo...

Glass-in-glass / Metal-in-metal inspection, small ...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

RaymanTech, as a leading provider of inspection an...

MoreAdvanced nut sorting machine technology combines H...

MoreFor processors, the challenge is evolving. It is n...

MoreIn the fast-paced world of food production, ensuri...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Thompson

Production ManagerThis frozen seafood optical sorter has revolutionized our processing line. The accuracy in identifying and removing defects is exceptional, and the speed has increased our throughput by 30%. Highly recommended for any seafood processing facility.

Sarah Chen

Quality Control SupervisorOutstanding performance! The sorter's advanced imaging system perfectly distinguishes between premium and substandard products. It has significantly reduced our manual sorting labor while improving overall product quality. The ROI was achieved in just 6 months.

David Rodriguez

Plant Operations DirectorVery impressed with the reliability and precision of this optical sorter. It handles various frozen seafood products with consistent results. The only minor issue was the initial setup required some technical support, but the customer service team was very responsive.

Jennifer Williams

Technical EngineerThis machine has exceeded our expectations in every aspect. The user-friendly interface, minimal maintenance requirements, and exceptional sorting accuracy make it worth every penny. It has become an indispensable part of our seafood processing operation.