Introduction to RaymanTech Optical Sorters for Farm Products and Food Processors

RaymanTech, as a leading provider of inspection an...

More

By 2026, AI, hyperspectral imaging, and robotic automation will dominate the industry. A modern green beans sorting machine delivers unprecedented accuracy, boosting produce quality and cutting waste.

Processors face challenges like initial investment costs and workforce training, but the potential for significant cost savings drives adoption.

The next wave of sorting technology moves beyond simple color and size checks. By 2026, three core technologies will work together to create an intelligent, precise, and automated sorting ecosystem: AI-powered optical sorters, hyperspectral imaging, and robotic automation. These systems provide processors with an unprecedented level of control over product quality.

Artificial intelligence elevates optical sorting from a mechanical process to a cognitive one. AI algorithms enable a modern green beans sorting machine to learn and adapt. It can identify defects with remarkable precision by analyzing vast datasets of images. This capability allows the system to recognize new or unusual flaws without manual reprogramming.

Traditional laser sorters are effective for detecting foreign materials and surface defects. However, AI-powered solutions offer a significant leap forward.

They achieve superior defect detection rates.

They minimize false positives, which reduces the waste of good products.

They adapt to new defect types by learning from processed data.

Modern systems often integrate AI with advanced laser and CCD imaging. This combination pushes sorting accuracy beyond 99%, ensuring that only the highest quality beans proceed to packaging.

Hyperspectral imaging (HSI) grants sorters the ability to see the invisible. While the human eye and standard cameras see in three bands of color (red, green, and blue), HSI captures data across hundreds of narrow spectral bands. This technology reveals the chemical and molecular composition of each green bean.

This "chemical fingerprinting" allows a green beans sorting machine to detect issues that are impossible to spot visually, such as moisture content, bruising beneath the surface, or the early stages of decay.

Research demonstrates the power of this technology. A study on green coffee beans used HSI to predict moisture content with an error margin of just 0.28%. By applying similar models, processors can visualize water distribution within individual green beans. This data is critical for ensuring shelf stability and consistent product quality. HSI provides a new layer of quality assurance that was previously unattainable.

Robotic automation completes the intelligent sorting loop. After optical and hyperspectral systems identify and classify each bean, robotic arms or high-speed air jets execute the physical sort. These systems operate with incredible speed and consistency, handling delicate produce gently to prevent damage.

Leading companies are driving innovation in this space. Firms like TOMRA Systems ASA, Key Technology, Inc., and Bühler AG develop integrated solutions that combine advanced imaging with precise robotic actuation. These platforms offer features such as:

Gentle product handling to preserve quality.

Real-time data analytics for process optimization.

Modular designs that scale with a processor's needs.

Robotic systems reduce reliance on manual labor for sorting tasks. They improve workplace safety and allow human workers to focus on higher-value roles, such as system monitoring and quality control management.

A modern green beans sorting machine combines advanced imaging, intelligent software, and precise mechanics to analyze and sort produce at incredible speeds. The process moves from identifying visible flaws to detecting hidden issues, all while protecting the product's integrity. This multi-stage approach ensures only the best beans reach the consumer.

Advanced sorters excel at finding tiny imperfections that manual inspection often misses. Spectroscopic imaging and computer-aided sensors improve product quality by removing defects and foreign materials. These systems use a combination of technologies to spot issues like insect bites, discoloration, or blemishes.

High-Resolution Cameras: These capture detailed images of each bean, allowing software to analyze color, shape, and texture.

Smart Camera Technology: This enables precise examination, detecting the smallest variations from the ideal product standard.

Laser Scanners: These contribute exceptional precision, identifying foreign material and surface irregularities with high accuracy.

Intelligent algorithms process this visual data, differentiating between acceptable variations and true defects to ensure an efficient and reliable sorting process.

The most advanced sorters see beyond the surface. They use specialized sensors to identify problems that are not visible to the naked eye. Technologies like InGaAs (Indium Gallium Arsenide) enhance the visibility of defects that share the same color as good products.

This allows the machine to differentiate between a cosmetic blemish and a quality-affecting issue, such as internal bruising or moisture variations.

Proprietary detection systems combine cameras and software to analyze the unique spectral characteristics of produce versus foreign materials. This "chemical fingerprinting" can identify issues like early-stage decay or inconsistent water content, which are critical for shelf stability.

Identifying a defective bean is only half the battle; removing it without damaging the surrounding good product is crucial. Modern systems use gentle but firm methods to execute the sort.

| Stage | Action | Technology Used |

|---|---|---|

| 1. Identification | The sorter scans and classifies each bean. | Cameras, Lasers, HSI |

| 2. Ejection | A targeted pulse removes the rejected bean. | High-speed air jets |

| 3. Collection | Good beans continue to the next stage. | Conveyor system |

This automated process minimizes physical impact, preserving the fresh quality of the green beans from the field to the packaging line.

Adopting advanced sorting technology provides processors with a clear competitive edge. The benefits extend beyond the sorting line, impacting product quality, operational efficiency, and even agricultural practices. These tangible returns justify the initial investment and position businesses for future growth.

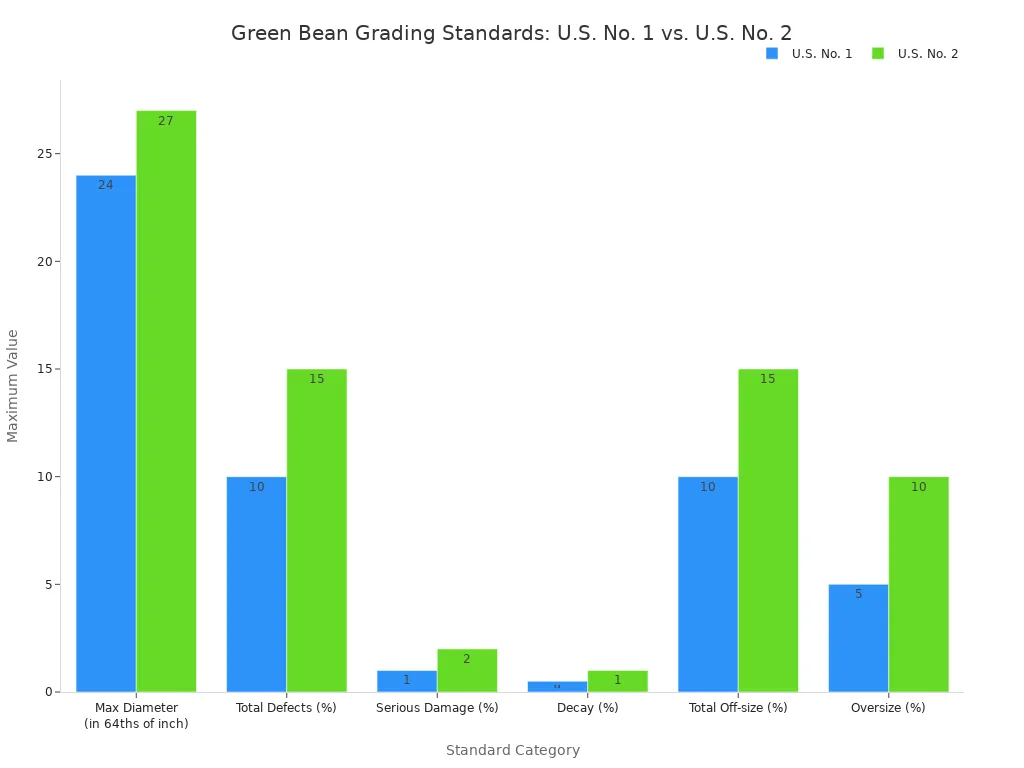

Modern sorters empower processors to meet and exceed stringent quality standards with unparalleled consistency. Government bodies like the USDA establish specific grades for produce, and advanced technology is the key to hitting the premium targets. For snap beans, the primary grades are:

U.S. No. 1

U.S. No. 2

Meeting the U.S. No. 1 grade requires exceptional precision. The technology must identify and remove beans with even minor damage while ensuring uniformity in size.

| Grade | Characteristics |

|---|---|

| U.S. No. 1 | Beans are fresh, tender, and free from damage caused by dirt, insects, disease, or mechanical injury. They must be properly trimmed. |

| U.S. No. 2 | Beans are fresh and tender but may have serious damage. The tolerance for defects is higher than for U.S. No. 1. |

Automated systems analyze each bean against these criteria, including strict tolerances for defects and size variations. This precision ensures that the final product consistently qualifies for a higher grade, which commands a better market price.

By automating this process, processors remove human subjectivity and fatigue, delivering a reliably premium product to consumers.

Automation dramatically increases throughput while simultaneously reducing product loss. A modern green beans sorting machine operates at speeds and accuracies that manual sorting cannot match. This efficiency translates directly into higher profitability.

A key financial benefit comes from waste reduction. The USDA estimates that improved sorting precision can decrease product waste by as much as 25%.

This reduction occurs because AI-powered systems minimize "false positives," which is the incorrect rejection of good products. Traditional sorters might discard a perfectly good bean due to a shadow or an unusual shape. Intelligent systems learn the difference, ensuring more high-quality product makes it to packaging. This not only boosts yield from the same amount of raw material but also contributes to a more sustainable operation.

Today's sorters are more than just sorting equipment; they are powerful data collection centers. They provide a constant stream of information that creates a feedback loop between the processing plant and the farm. Karel Van Velthoven of Key Technology notes that processors use this data to optimize their entire line, extending benefits back to the grower.

Sorters collect detailed information on every bean that passes through them. This data includes:

Yield Data: Overall pass/fail rates and the percentage of product sorted into different quality grades.

Defect Data: The type and frequency of each defect, such as insect damage, discoloration, or mechanical breakage.

Quality Data: Metrics on size, shape, and even moisture content uniformity.

Processors can analyze this data to make fact-based decisions. For example, Vincent Godin of Emblème Canneberge uses analytics to monitor defect types. If he sees a spike in a certain kind of blemish, he can advise the grower to adjust their cultivation methods for the next crop. This data-driven approach replaces guesswork with actionable intelligence, helping farmers optimize raw material quality and improve future yields. This information also aids in supply chain management, allowing for better demand forecasting and supplier selection based on historical performance.

While the benefits are clear, processors must navigate several significant challenges before successfully implementing advanced sorting technology. These hurdles involve financial justification, technical integration, and workforce development. Addressing them proactively is key to a smooth transition.

The high initial cost of AI-powered sorters is a primary barrier for many processors. A comprehensive Return on Investment (ROI) calculation is essential to justify the expense. This analysis must extend beyond the machine's price tag. It should account for long-term financial gains, including increased throughput, higher yields from waste reduction, and the premium prices commanded by consistently high-grade products. A thorough ROI model demonstrates how the technology pays for itself over time through operational improvements.

Connecting a new sorter with existing factory management software presents a complex technical challenge. Incompatible systems and data inconsistencies can cause significant operational delays and disrupt productivity. Key integration issues include:

Incompatible Software Versions: Mismatched software can cause breakdowns in automated manufacturing processes.

Data Inconsistency: Duplicated or conflicting data slows down production monitoring and quality control.

Lack of Standard Formats: The absence of universal data standards complicates information exchange between systems.

Successfully integrating these applications requires careful planning to ensure seamless data flow and flexible adaptation to future business needs.

Modern sorting equipment demands a shift from manual labor to skilled technical oversight. Employees need new competencies to operate, maintain, and troubleshoot these sophisticated systems.

Operators must possess strong problem-solving abilities and mechanical aptitude to diagnose issues, perform routine maintenance, and keep production moving efficiently.

This requires a workforce proficient in interpreting technical manuals and managing computerized controls. To address this skills gap, equipment manufacturers offer specialized training programs, such as certifications in mechatronics sorting and distribution, to prepare employees for the modern processing environment.

The future of green bean sorting is intelligent, precise, and automated. AI, hyperspectral imaging, and robotics are no longer futuristic concepts; they are practical tools for improving quality and profitability.

With technology adoption accelerating and government programs like the Environmental Quality Incentives Program (EQIP) available, the time for processors to plan their investment is now.

AI-powered optical sorters, hyperspectral imaging, and robotic automation are the core technologies. They identify defects, analyze chemical composition, and automate the physical sorting of green beans with high precision.

AI algorithms improve sorting accuracy. They minimize false positives, preventing the system from discarding good beans. This practice increases overall yield and reduces food loss during the processing stage.

The initial cost presents a challenge. However, a detailed ROI calculation often reveals long-term savings. Increased efficiency, less waste, and premium product prices can justify the investment for many operations.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Recommedation: Small particle, flat products such...

Recommedation: Chili, walnut, peanuts, soybeans, c...

Both fat analysis and contaminant inspection (bone...

Recommedation: Chili, walnut, peanuts, soybeans, c...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

RaymanTech, as a leading provider of inspection an...

MoreAdvanced nut sorting machine technology combines H...

MoreIn the fast-paced world of food production, ensuri...

MoreAs global demand for premium, safe meat products ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Production SupervisorThis green bean sorting machine has revolutionized our processing line. The accuracy and speed are exceptional, reducing our manual labor costs by 60%. The color recognition system perfectly identifies and removes defective beans.

Sarah Chen

Quality Control ManagerOutstanding performance! The machine's precision in sorting by size and color has significantly improved our product quality. Minimal maintenance required and the user interface is very intuitive. Highly recommended for any vegetable processing facility.

David Thompson

Farm Operations DirectorExcellent investment for our organic green bean operation. The gentle handling preserves bean quality while efficiently removing foreign materials. Setup was straightforward and the technical support team was very responsive.

Jennifer Williams

Processing Plant ManagerThis sorting machine has exceeded our expectations. The throughput matches exactly what was promised, and the defect removal rate is impressive. It has helped us maintain consistent quality across all our green bean batches.