Revolutionizing Quality Control with Advanced Hazelnuts Sorting Machines

Advanced nut sorting machine technology combines H...

More

The coffee roaster market projects an annual growth rate near 6.7%, increasing the demand for efficient tools. A quality green coffee beans optical sorter is vital for consistency. Top models for smaller operations include the Bühler SORTEX H SpectraVision, Satake PIKASEN FMS2000, Coffee Color Sorter MINI-125, Delta Technology I-R-G-S Series, and the Anysort Cloud Series Mini. These selections balance performance, footprint, and cost.

Choosing the right sorter requires a close look at what each machine offers. The following reviews break down the capabilities, strengths, and ideal use cases for each of our top 5 picks, helping you find the perfect match for your roastery's needs.

Bühler sets an industry benchmark with the SORTEX H SpectraVision. This machine is engineered for roasteries that demand the highest level of precision. It features newly designed full-color cameras for superior color differentiation. The sorter also integrates advanced InGaAs cameras for exceptional foreign matter detection. This technology delivers up to 50% higher reject concentrations, ensuring minimal loss of good beans.

The SORTEX H SpectraVision stands as one of the highest-performing optical sorters available. Its power comes from high-capacity processing and an advanced lighting system. The machine uses LEDs that provide triple the light of many competitors, illuminating challenging defects. Furthermore, Bühler's MerlinAI engine simplifies operation. The system self-adjusts and automatically assigns sorting modes for peak performance with minimal user input.

Expert Tip: The SORTEX H is ideal for roasters specializing in high-end micro-lots where removing even the most subtle defects is critical to preserving the coffee's value and flavor profile.

The Satake PIKASEN FMS2000 offers a powerful sorting solution in a compact frame. It is a full-color RGB optical sorter designed for efficiency and ease of use. The machine processes up to 4,000 pounds of product per hour, making it a versatile choice for growing roasteries. Its full-color RGB cameras use low-energy lighting to uniformly illuminate each bean. The sorter then evaluates every item against user-defined color criteria to accept or reject it with precision.

This model packs numerous features into its small footprint:

Full-color RGB cameras with 0.14mm/pixel resolution

An intuitive touch screen interface similar to a smartphone

The Satake Smart Sensitivity (3S) system for easy setup

Optional integrated aspiration to remove dust

Roller wheels for simple mobility within the facility

The PIKASEN FMS2000 is an excellent green coffee beans optical sorter for businesses needing both high throughput and operational flexibility.

The Coffee Color Sorter MINI-125 is a purpose-built machine designed specifically for the specialty coffee industry. It provides exceptional defect removal at a scale and price point accessible to small and medium roasteries. The sorter uses a custom 54-megapixel camera. A unique algorithm helps this camera identify even the smallest imperfections in coffee beans.

This sorter excels at identifying a wide range of common and difficult defects. Its precision allows roasters to achieve a cleaner, more consistent final product. Key defects it can remove include:

Quackers (underdeveloped beans)

Insect damage

Foreign materials like stones and dirt

Black, white, and discolored beans

Broken or shelled beans

Its focused design makes it a top contender for roasters who prioritize cup quality and want a straightforward, effective sorting solution.

Delta Technology is known for building robust and reliable sorting equipment. The I-R-G-S Series brings this industrial-grade quality to a scale suitable for smaller operations. This series combines multiple technologies, including Infrared (IR), Green (G), and Red (R) sensors, to provide comprehensive defect analysis. This multi-spectrum approach enables the machine to detect issues that a standard color camera might miss.

The I-R-G-S Series is a dependable workhorse. Roasters appreciate its durable construction and consistent performance. The user interface is designed for practicality, allowing operators to easily configure sorting parameters and monitor performance. For a roastery seeking a long-term, low-maintenance green coffee beans optical sorter that delivers consistent results day after day, the Delta Technology I-R-G-S is a strong investment.

The Anysort Cloud Series Mini brings cutting-edge AI and cloud connectivity to the roastery floor. This sorter leverages cloud intelligence for one-button operation. The system can recognize, analyze, and calculate input impurities to adjust sorting data automatically. This feature greatly simplifies complex sorting tasks.

Its innovative cloud function enables remote control and maintenance. The machine can even send status updates and error messages via push email. Key features include:

AI Capabilities: Shape recognition and optional infrared technology identify impurities like glass or stones.

Cloud Intelligence: Simplifies operations through automatic analysis and adjustment.

AI Variable Light Control: Uses advanced infrared spectroscopy and neural network algorithms for accurate material analysis.

The Anysort Cloud Control 2.0 AI system can integrate the entire production line, minimizing waste and unlocking value through precision sorting.

| Model | Throughput (t/h) | Power (kW) |

|---|---|---|

| VM164+ | 0.5-2 | 1.5 |

This model is perfect for the tech-forward roastery looking to leverage data and automation for ultimate efficiency and quality control.

Selecting the right machine involves more than just comparing models. Roasters must evaluate several key factors to ensure the sorter aligns with their operational needs, quality standards, and budget. A careful analysis of these areas will lead to a successful long-term investment.

Roasteries must match a sorter's throughput to their production volume. A machine with insufficient capacity creates bottlenecks, while an oversized one is an unnecessary expense. Many single-layer coffee sorters can process up to 2 tons per hour, suiting medium-sized operations. For smaller roasteries using 15–70 kg machines, a model like the Pearl Mini offers a targeted capacity of up to 500 kg per hour for green coffee.

A sorter's primary function is to improve coffee quality by removing defects. The Specialty Coffee Association (SCA) classifies defects into two categories based on their impact on cup quality. A capable green coffee beans optical sorter should identify both.

Primary Defects (Category 1): Full black, full sour, fungus damage, foreign matter.

Secondary Defects (Category 2): Partial black, insect damage, floaters, broken beans.

The ability to remove these imperfections consistently is crucial for producing a specialty-grade product.

Space is often a premium in small roasteries. It is vital to measure the available area and compare it to a sorter's dimensions. Compact models are designed specifically for tight spaces.

| Model | Weight (kg) | Dimensions (L x W x H mm) |

|---|---|---|

| Coffee Color Sorter MINI-125 | 180 | 1000 x 600 x 1200 |

Operators must also consider utility requirements. Sorters need specific power and compressed air supplies for operation.

| Utility Type | Specification |

|---|---|

| Power Voltage | 220V/50HZ/60HZ |

| Air Pressure | 0.6-0.8 Mpa |

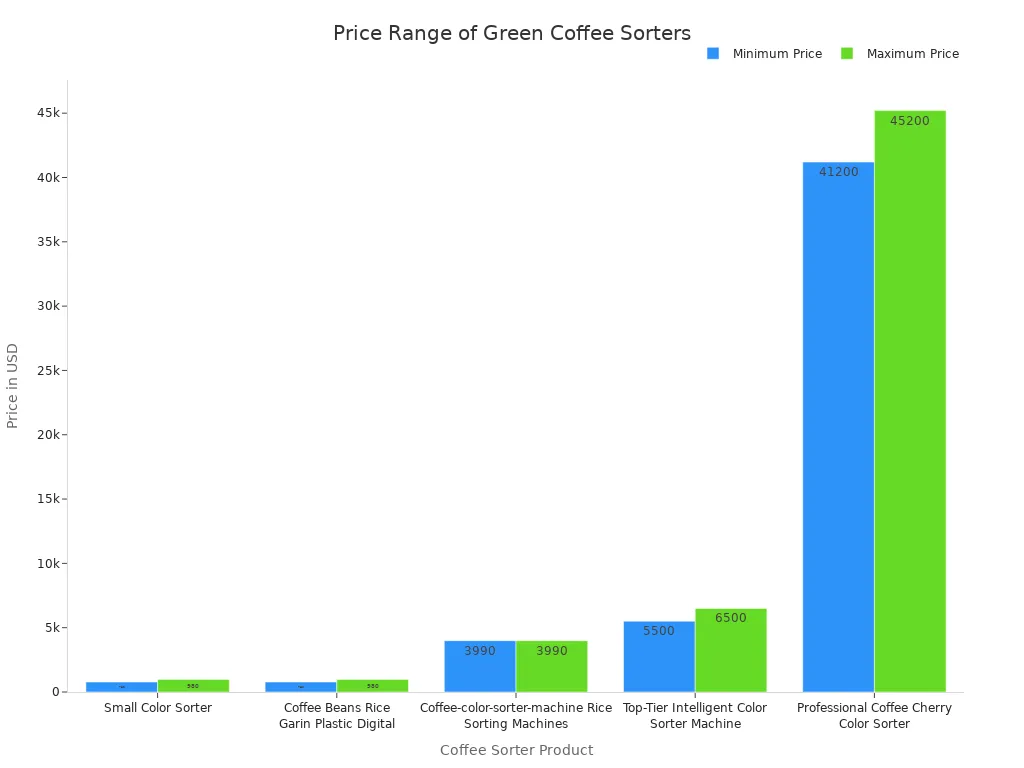

Prices for coffee sorters vary significantly. Entry-level machines can be found for under $1,000, while high-end professional equipment can exceed $40,000.

Roasters should view this purchase as an investment. A sorter improves efficiency, reduces labor costs, and enhances final product quality, leading to a strong return over time.

Evaluating these top-tier machines side-by-side clarifies their unique strengths. This direct comparison helps roasters align a sorter’s features with their specific operational priorities and quality goals.

This table provides a snapshot of each model's core attributes. Roasters can use it to quickly identify which machine best fits their needs.

| Model | Key Technology | Ideal For | Special Feature |

|---|---|---|---|

| Bühler SORTEX H | SpectraVision & InGaAs | High-end micro-lots | MerlinAI self-adjustment |

| Satake PIKASEN | Full-Color RGB | Growing roasteries | High throughput (4,000 lbs/hr) |

| CCS MINI-125 | 54MP Custom Camera | Specialty coffee focus | Excels at removing quackers |

| Delta I-R-G-S | Infrared & RGB | Long-term reliability | Robust, industrial build |

| Anysort Cloud Mini | AI & Cloud Connectivity | Tech-forward roasteries | Remote operation & analysis |

A systematic approach ensures a successful purchase. Roasters should complete this checklist before committing to a new green coffee beans optical sorter.

Note: Always request a product demonstration using your own green coffee. This provides the most accurate assessment of a sorter's performance with your specific product.

✅ Assess Current and Future Volume: Calculate your weekly green coffee usage. Project your growth over the next three to five years to choose a sorter with adequate capacity.

✅ Identify Critical Defects: Determine the most common defects in your green coffee supply. Ensure your chosen sorter can effectively target and remove them.

✅ Verify Facility Compatibility: Measure your available floor space. Confirm that your power supply and compressed air system meet the machine’s requirements.

✅ Evaluate Software and Usability: Review the user interface. A machine with an intuitive system reduces training time and operational errors.

✅ Inquire About Support: Ask about warranty, technical support, and the availability of spare parts. Reliable post-purchase support is essential for minimizing downtime.

For overall value, roasters should consider the Coffee Color Sorter MINI-125. The Bühler SORTEX H SpectraVision offers unmatched precision for high-end needs. Investing in a quality green coffee beans optical sorter directly boosts quality. High-precision machines can elevate cup scores by two to three points, streamlining operations and ensuring consistency.

Optical sorters offer unmatched speed and consistency. They reduce labor costs significantly. The machines detect subtle defects the human eye misses, which directly elevates the final cup quality.

Maintenance involves daily cleaning of cameras and chutes. Weekly checks of air ejectors and system calibration are also standard. Following the manufacturer's schedule ensures consistent, reliable performance.

These sorters are calibrated for green coffee's density and color. Sorting roasted beans is not their primary function and may require different equipment or specific model capabilities.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Conventional and unconventional contaminant detect...

Recommedation: Rice, wheat, corn, grain, pulses, s...

Recommedation: Chili, walnut, peanuts, soybeans, c...

Recommedation: Frozen vegetables such as green be...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Advanced nut sorting machine technology combines H...

MoreRaymanTech, as a leading provider of inspection an...

MoreFrom sweet corn and peas to green beans and vegeta...

MorePistachios are a premium, high-value commodity. Co...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Production ManagerThis green coffee beans optical sorter has revolutionized our quality control process. The accuracy in detecting defects is remarkable, and it has significantly reduced our manual sorting time. A game-changer for any serious coffee processor.

Sarah Chen

Quality Assurance SpecialistOutstanding performance and reliability! The optical sorter consistently identifies even the smallest defects with precision. The user interface is intuitive, and maintenance requirements are minimal. Highly recommended for specialty coffee producers.

James Wilson

Operations DirectorExcellent investment that paid for itself within the first year. The sorting speed and accuracy have improved our overall product quality while reducing labor costs. The only minor drawback is the initial learning curve for operators.

Emily Thompson

Plant SupervisorAfter using this optical sorter for six months, our defect rate has dropped by 85%. The machine's consistency and the excellent technical support make it worth every penny. It has become an indispensable part of our production line.