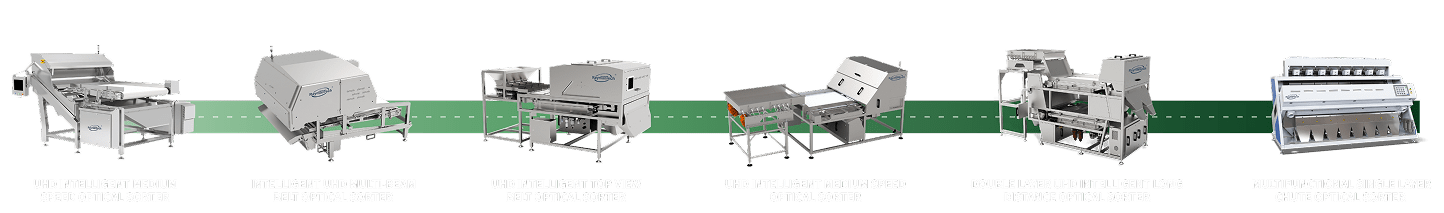

Introduction to RaymanTech Optical Sorters for Farm Products and Food Processors

Optical sorting has become a cornerstone of modern food production, agricultural processing, and quality assurance. As global consumers demand safer, cleaner, and more consistent products, processors at every stage—from raw material handling to final packaging—turn to advanced automated technologies to remove defects and foreign materials. RaymanTech, as a leading provider of inspection and sorting solutions, has developed a comprehensive optical sorter portfolio that now serves both farm-product applications and food-processing environments. While farm-product sorters focus on capacity, adaptability, and raw-material variability, food-processor-grade sorters must also incorporate high IP protection, robust stainless-steel construction, sanitary design, and harsh washdown compatibility.

1. RaymanTech Optical Sorters for Farm Products

RaymanTech's optical sorters for agricultural raw materials are designed for environments where products originate from farms, plantations, or primary collection centers. These materials—such as nuts, seeds, grains, coffee beans, dried fruits, spices, and legumes—often have natural variations in size, shape, color, and moisture. Defect types can include pods, stones, shells, foreign seeds, discolored kernels, moldy pieces, immature products, and more.

1.1 Multi-Spectrum Imaging Technology

RaymanTech utilizes multi-spectrum imaging, which combines: visible light imaging, near-infrared (NIR), shortwave infrared (SWIR) and optional hyperspectral imaging. These systems allow operators to detect a wide range of impurities that a single-color camera cannot identify.

1.2 High-Resolution Cameras and Advanced Optics

RaymanTech integrates high-speed industrial cameras capable of capturing microscopic defects at high frame rates. The company's long-distance optical designs support deeper depth-of-field imaging, enabling high-capacity sorting without losing clarity or stability.

1.3 AI-Powered Recognition Algorithms

Traditional rule-based sorting can struggle with complex materials. RaymanTech's AI algorithms analyze:

- Surface texture

- Shape complexity

- Subtle color gradations

- Mixed-material boundaries

- Natural product irregularities

This results in improved identification of hard-to-detect defects, such as partially damaged kernels, minor discoloration, or contaminants with similar appearance to the product.

1.4 Multi-Sensor Fusion

To address materials with diverse defect signatures, RaymanTech combines multiple sensors:

- Color cameras

- NIR sensors

- Shape detectors

- Infrared absorption modules

By merging sensor outputs, the sorter constructs a more complete understanding of each object's characteristics, increasing accuracy and reducing false rejects.

1.5 Precision Ejection System

RaymanTech uses high-speed, low-air-consumption ejectors designed to remove only defective items while minimizing waste of good product. Ejector spacing and air pressure can be customized according to material size, helping processors achieve premium-grade product quality.

These capabilities make RaymanTech's farm-product optical sorters suitable for a wide range of agricultural operations, where consistency, speed, and reliability are essential.

2. RaymanTech Optical Sorters for Food Processors: High IP Protection and Hygienic Washdown Design

Compared with farm-product sorting, food processing environments—especially those handling meat, seafood, frozen vegetables, ready-to-eat foods, or post-washing agricultural materials—require much stricter sanitation and equipment protection standards. RaymanTech has engineered a dedicated series of food-grade optical sorters specifically for processors who must maintain compliance with HACCP, FSMA, GFSI, BRC, and other global food-safety systems.

2.1 IP65, IP66, and IP69K Water and Dust Protection

Food factories often perform daily high-pressure cleaning with chemicals, hot water, and sanitizing agents. RaymanTech's food-grade optical sorters can be configured with advanced IP protection:

- IP65: Dust-tight and resistant to low-pressure water cleaning

- IP66: Withstands high-pressure water spray

- IP69K: Survives high-pressure, high-temperature washdown for the most demanding hygiene environments

These protection levels prevent ingress of water, detergents, lubricants, and dust, significantly extending the machine's service life in wet processing rooms.

2.2 Full Stainless-Steel Structure and Hygienic Design

Food processors require machines that are not only washable but also designed to avoid bacterial accumulation. RaymanTech incorporates:

- 304 or 316 stainless steel frames, covers, and fasteners

- Rounded edges to avoid residue traps

- Smooth, polished surfaces that resist corrosion and microbial adhesion

- Sloped panels for natural drainage

- Waterproof bearing housings

- Fully sealed electrical compartments

- Corrosion-resistant conveyor frames and components

This hygienic engineering reduces risk during wet cleaning and supports factory sanitation protocols.

2.3 Wash-Friendly Components and CIP-Compatible Modules

Recognizing the high cleaning frequency in food plants, RaymanTech integrates features that minimize downtime:

- Quick-release and tool-free belt removal

- Washdown-resistant air pipes, ejectors, and nozzles

- Waterproof lamp housings and sensor covers

- Removable product-contact parts

- CIP-friendly internal layouts (optional in certain models)

- Anti-corrosion fasteners and gasket seals

These features ensure that cleaning cycles are faster, more effective, and safer for both equipment and operators.

2.4 Optical and Software Enhancements for Food Products

Food processors handle different types of materials than farm-product suppliers. For example:

- IQF vegetables and fruits contain frost, moisture, and color variations

- Seafood products may include shells, black spots, soft tissues, and foreign objects

- Frozen food ingredients may contain shape-defining defects

- Ready-to-eat ingredients require extremely high purity

To support these challenges, RaymanTech provides:

- Enhanced color calibration for frozen materials

- Adaptive lighting for wet or reflective surfaces

- AI models trained for soft, irregular food items

- Specialized shape recognition for diced or cut products

- Moisture-resistant sensors

These innovations maintain high sorting accuracy even in harsh environments.

2.5 Foreign Object and Defect Removal for Food Processors

Food-grade optical sorters target a wider range of defects, such as:

- Foreign materials: plastic, wood, insects, shells, stones, metal-like contaminants

- Defects: discoloration, burn marks, bruises, mold, spoilage

- Quality grading: size uniformity, shape sorting, ripeness categorization

When combined with RaymanTech's X-ray machines or metal detectors, processors can form a complete inspection line that meets international food-safety standards.

3. End-to-End Quality Control Across the Supply Chain

One of RaymanTech's greatest advantages is the ability to serve both the agricultural upstream and the food-processing downstream. This allows customers to build integrated quality systems from raw material intake to final product packaging.

Applications across the supply chain include:

- Pre-cleaning at farms and collection centers

- Sorting before hulling, roasting, or drying

- In-process sorting during mixing, blending, freezing, or cooking

- Final defect removal before packing

- Quality grading for premium export products

- Safety control for ready-to-eat or high-value ingredients

By covering all stages, RaymanTech helps manufacturers reduce waste, control costs, improve consistency, and protect brand reputation.

4. Conclusion

RaymanTech's optical sorter portfolio reflects the company's commitment to engineering excellence and practical problem solving. For agricultural raw materials, RaymanTech offers adaptable, high-capacity, and AI-enhanced systems capable of handling the natural variability of farm products. For food processors, RaymanTech delivers robust, hygienic, and high-IP-rated equipment engineered for heavy washdown, industrial cleaning chemicals, and strict food-safety environments.

Together, these solutions enable processors to achieve higher efficiency, stronger compliance, and more consistent product quality. As global food-safety expectations continue to rise, RaymanTech's innovations in imaging, sensor fusion, AI recognition, and hygienic engineering position the company as a trusted partner for modern, automated production facilities.

Related Articles

-

Nov-18-2025

Nov-18-2025Overcoming Challenges in Large Package: Rayman Tech's AI X-ray Solutions for Meat Processing

Our AI X-ray Inspection System, tailored for high and low-density contaminant detection, bone inspection, and defect analysis, is particularly suited for the meat industry. By integrating AI-driven algorithms and advanced hardware, we help food processors achieve compliance with stringent safety standards while boosting efficiency. If you're searching for reliable large package X-ray inspection solutions, read on to discover how our technology stands out.learn more -

_1.png) Nov-18-2025

Nov-18-2025Maximizing Walnut Purity: A Guide to Optical Sorting Machines

From shell fragments and septa to mold and shriveled kernels, ensuring product purity is a labor-intensive and imperfect process when done manually. This is where advanced inspection technology becomes essential. A high-performance walnuts optical sorting machine is no longer a luxury—it is a critical component for any competitive processor looking to enhance food safety, maximize yield, and protect their brand reputation.learn more

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057