RaymanTech Whole-Chain Solution: A Deep Dive

Food safety and quality control demands have evolv...

More

Modern, high-quality mustard seed processing requires advanced technology. Optical sorters provide unparalleled precision, surpassing older vibrating sieves. Sieves separate seeds by physical size alone. A modern mustard seeds sorting machine, however, uses advanced imaging to analyze each seed for color, shape, and texture, ensuring superior purity in a rapidly expanding global market.

| Metric | Value |

|---|---|

| Estimated Market Size (2024) | USD 6.67 billion |

| Projected Market Size (2030) | USD 9.53 billion |

| CAGR (2025-2030) | 6.1% |

Understanding the operational differences between sorting technologies reveals why one is superior for modern processing. Each machine approaches the task of purification from a fundamentally different perspective.

Vibrating sieves separate mustard seeds using a purely mechanical process based on physical dimensions. This traditional method relies on a multi-deck system to achieve classification.

Vibration Generation: Powerful motors create consistent vibrations across the entire sieve structure.

Material Input: Seeds enter at the top and spread across the first screen layer.

Layered Screening: The machine contains multiple screens with progressively smaller mesh sizes from top to bottom.

Size Separation: As the machine vibrates, larger seeds and foreign materials remain on the upper layers. Smaller seeds pass through to lower decks for further refinement.

Dedicated Output: Each layer funnels its sorted material to a separate outlet, completing the size-based classification.

Optical sorters move beyond simple mechanics, using advanced imaging to sort with incredible precision. An AI-powered mustard seeds sorting machine inspects and categorizes items based on a wide range of quality traits.

This technology uses deep learning algorithms to improve its sorting capabilities over time. With each pass, the machine enhances its ability to identify subtle issues like small bruises, discoloration, or early signs of rot. It can even adapt to changes in lighting or product appearance without manual recalibration.

High-resolution cameras capture images of every single seed. The system’s software then analyzes these images in milliseconds, checking for defects in color, shape, and texture. When the sorter identifies a defective seed, it signals a precise puff of compressed air to eject it from the main stream, ensuring only the highest quality seeds proceed.

When evaluating sorting technology, performance metrics provide a clear, objective comparison. Accuracy, purity, throughput, and efficiency are the pillars that determine a machine's true value in a modern processing facility.

Accuracy in seed sorting extends beyond simple size classification. True accuracy involves identifying and removing all unwanted material to achieve the highest possible product purity.

Vibrating sieves operate on a single principle: size. They effectively separate oversized debris and undersized seeds. However, their limitation is significant. A sieve cannot distinguish a healthy mustard seed from a discolored one, a stone of the same size, or a seed damaged by pests. This mechanical-only approach inherently caps the final purity level, as many defects pass through with the acceptable product.

Optical sorters, by contrast, achieve unparalleled precision. They can reach a final product purity of 99.9% by targeting a wide spectrum of defects.

This advanced mustard seeds sorting machine uses high-resolution imaging to analyze each seed for:

Color Defects: Removing seeds that are yellowed, browned, or otherwise discolored.

Shape and Size Deviations: Ejecting broken seeds or foreign grains.

Textural Imperfections: Identifying shriveled or damaged seeds that sieves would miss.

This ability to see and reject individual defects ensures the final batch is exceptionally clean, uniform, and free of contaminants.

Throughput measures the volume of seeds processed per hour, while operational efficiency reflects the machine's uptime and maintenance needs. While both are designed for continuous operation, their demands on labor and time differ dramatically.

Sieves can handle large volumes, but their mechanical nature requires frequent and hands-on maintenance to prevent downtime and ensure consistent performance. Proactive upkeep is essential.

Regular Cleaning: Operators must remove residual seed build-up after each use to prevent screen clogging and cross-contamination.

Inspection Checklist: Staff needs to check screen tension, tighten loose bolts, and monitor the motor for signs of wear.

Consumable Parts: Gaskets, seals, and other rubber components require constant visual inspection and replacement.

Optical sorters are engineered for maximum uptime with minimal human intervention. Their maintenance schedule is far less demanding, with many systems featuring automated self-care. This design keeps the production line running smoothly with greater efficiency.

| Maintenance Task | Frequency | Action |

|---|---|---|

| Clean Optics and Sensors | Automatic | The system self-cleans when dust is detected on camera shields. |

| Check for Loose Components | Once a year | An annual inspection of mounts, cables, and screws is sufficient. |

| Inspect Reject Mechanism | Yearly | Technicians look for wear or misalignment and lubricate parts as needed. |

| Review Software and Firmware | Monthly | A quick check ensures the system has the latest updates. |

The contrast is clear. Sieves demand consistent manual labor for cleaning and upkeep, whereas an optical sorter automates most routine maintenance, freeing up personnel and maximizing operational hours.

Choosing between traditional and modern sorting technology requires a careful analysis of both upfront costs and long-term value. While a vibrating sieve presents a lower initial expense, an optical sorter delivers a far greater return on investment through enhanced efficiency, superior product quality, and reduced waste.

The initial purchase price is often the first factor businesses consider. Vibrating sieves offer a more accessible entry point for processors on a tight budget. The cost for these mechanical units can vary based on size, capacity, and features. Some industrial-grade screeners have negotiable prices, while others fall into a more defined range.

| Product Description | Price Range |

|---|---|

| Mechanical Sieve Shaker Price Vibrating Sieve for Seed | $2,800 |

| Small Sand Mechanical Sieve Shaker Price | $3,590 - $5,989 |

| Best-Selling Industrial Mechanical Sieve Shaker | $3,450 - $4,100 |

Optical sorters represent a more significant capital investment. The advanced technology, including high-resolution cameras, complex software, and precision ejectors, places their initial cost substantially higher than mechanical sieves. However, the purchase price is only part of the total initial outlay. Installing an optical sorter often requires specific infrastructure preparations that add to the upfront expense.

Note: A successful installation depends on a thorough site assessment. Processors must account for several key factors before the machine arrives.

Key infrastructure requirements include:

Location and Structural Needs: The facility must have adequate floor load capacity to support the machine's weight and sufficient ceiling height for installation and maintenance access.

Power and Electrical Systems: Optical sorters are sophisticated electronic systems. They demand a stable and properly configured power supply to prevent operational failures.

Safety and Environmental Protocols: The installation area must comply with all safety regulations to protect operators and the equipment.

Production Line Integration: Planners must ensure the new sorter integrates seamlessly with existing conveyors and other machinery to create a cohesive workflow.

While the initial cost of an optical sorter is higher, its long-term value provides a compelling financial argument. The return on investment (ROI) is not measured in years of service but in months of increased profitability. Industry experts report that the payback period for optical sorting equipment often ranges from a few months to three years. For facilities running multiple shifts, this ROI can be achieved even faster.

Leading manufacturers like the Bühler Group note that the initial investment can be recouped within a few years based on the increase in yield alone. This rapid return is driven by three primary factors:

Maximized Yield: Optical sorters recover a higher percentage of acceptable seeds that sieves might discard. They also prevent good products from being lost with rejected materials. A case study in a tomato facility, for example, showed a remarkable 25% increase in yield after implementing an optical sorter.

Reduced Waste: By precisely targeting only defective items, the mustard seeds sorting machine minimizes the rejection of good products, turning potential waste back into revenue.

Premium Product Value: The exceptional purity (99.9%) achieved by optical sorters allows processors to market their mustard seeds as a premium product, commanding higher prices and accessing new, quality-focused markets.

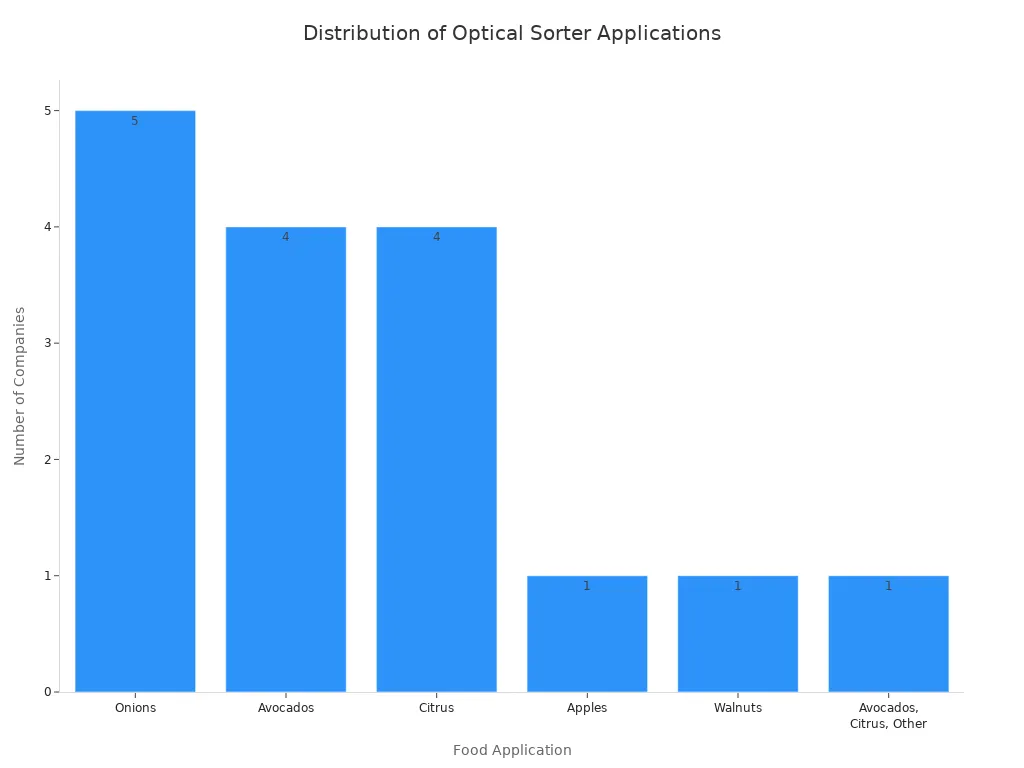

The adoption of this technology is widespread across the food industry, confirming its financial viability. Companies processing everything from onions and avocados to citrus and nuts have successfully integrated optical sorters to boost their bottom line.

This broad implementation, from Bybee Produce in the United States to Valnoce in Italy and Afrupro in South Africa, demonstrates a global consensus. Businesses that invest in optical sorting gain a powerful competitive advantage, securing profitability through operational excellence and superior product quality.

The sorting method directly influences the final product's marketability and safety. Optical sorters provide superior control over quality attributes, elevating the product far beyond what mechanical sieves can achieve.

Visual consistency is a primary indicator of premium quality. Industry standards require uniformity in both size and color, as mixed batches suggest inferior processing. A modern mustard seeds sorting machine excels at meeting this expectation. Advanced models use full-color RGB cameras with an optical resolution as fine as 0.06 mm. This technology allows processors to detect the slightest shade variations, ensuring every seed in the final batch has a uniform appearance. This capability creates a visually appealing product that commands a higher price in the market.

Beyond aesthetics, sorting technology is critical for food safety and taste integrity. Optical sorters effectively remove dangerous foreign materials that sieves cannot detect.

Glass

Stones

Plastic

Foreign seeds

This process protects consumers from physical hazards. Furthermore, these sorters safeguard flavor by eliminating biological contaminants. Using technologies like UV light, they can identify mold-infected seeds that produce mycotoxins and off-flavors. The system detects a fluorescent glow from the fungus and uses precise air jets to eject the contaminated seeds. This early removal prevents toxins from spreading and ensures the final product is safe, pure, and flavorful.

Optical sorters definitively surpass sieves in accuracy, speed, and quality assurance. This technology is a strategic investment, enhancing product value and securing profitability. Processors gain a competitive edge, paving the way for future advancements like NIR and SWIR sorting, ensuring long-term success in a demanding market.

Optical sorters provide superior purity and efficiency. They identify and remove non-uniform seeds, foreign materials, and other defects that sieves miss, significantly increasing final product value.

Yes. Processors can easily configure the AI-powered software for various seed types. The system adapts to different sizes, colors, and quality specifications, ensuring flexible and precise sorting operations.

This technology enhances safety by removing dangerous contaminants. It accurately detects and ejects:

Stones, glass, and plastic

Mold-infected seeds that produce mycotoxins

This ensures a safer, purer product for consumers.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Recommedation: Chili, walnut, peanuts, soybeans, c...

Ultra-fine contaminants detection, UHD X-Ray detec...

Automatic recognition and rejection, fish bone ins...

Glass-in-glass / Metal-in-metal inspection, small ...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Food safety and quality control demands have evolv...

MorePistachios are a premium, high-value commodity. Co...

MoreAdvanced nut sorting machine technology combines H...

MoreIn the fast-paced world of food production, ensuri...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Robert Johnson

Farm ManagerThis mustard seeds sorting machine has revolutionized our processing line. The accuracy and speed are remarkable, significantly reducing our manual labor costs.

Sarah Chen

Quality Control SupervisorExcellent machine with precise sorting capabilities. The color and size sorting accuracy exceeds 98%, ensuring only premium quality seeds move to packaging.

Michael Rodriguez

Production EngineerReliable and efficient machine that handles large volumes effortlessly. The automated cleaning system minimizes downtime between batches.

Emily Watson

Operations DirectorOutstanding investment for our spice company. The machine's gentle handling preserves seed integrity while maintaining high throughput of 500kg per hour.