Revolutionizing Quality Control with Advanced Hazelnuts Sorting Machines

Advanced nut sorting machine technology combines H...

More

The agricultural sorting equipment market is projected to reach $13.91 billion in 2025. This growth highlights the importance of efficient technology. A modern peppers sorting machine boosts productivity for medium-sized farms. The best models for 2025 offer distinct advantages.

1. Raytec Vision Dryce: For its advanced defect and blemish detection.

2. CDS Manufacturing OptiSort-P5: For its superior color and size grading accuracy.

3. Hefei Meritech CS-3000: For its excellent value and budget-friendly operation.

4. Agro-Tech VersaSorter 4X: For its versatility in handling diverse pepper varieties.

5. GI AGRO FlowMaster 5000: For its unmatched high-volume throughput.

Choosing the right sorting equipment requires a deep dive into what each model offers. The following reviews break down the specific strengths, technologies, and ideal applications for each of our top five picks. This analysis will help you align a machine’s capabilities with your farm’s operational goals.

The Raytec Vision Dryce excels at identifying and removing imperfect peppers. Its primary strength lies in its advanced inspection technology. The machine ensures that only the highest quality produce reaches the final packaging stage. This focus on quality control protects brand reputation and maximizes the value of each harvest.

The Dryce sorter utilizes a unique "Decaray" technology. This system combines pulsed LED lighting with specialized cameras to detect a wide range of issues. It identifies everything from sunscald and blossom end rot to insect damage and mechanical bruising. Its 3D laser scanning capabilities also allow it to analyze the shape and volume of each pepper, rejecting malformed products with high accuracy.

💡 Key Feature: The Dryce's software uses machine learning algorithms. It continuously improves its sorting accuracy by learning from the product stream, adapting to subtle variations in defect presentation throughout the season.

Core Strengths:

Superior Defect Analysis: Detects color, shape, and biological defects.

3D Reconstruction: Ejects peppers based on physical deformities.

Chlorophyll Correction: Accurately assesses ripeness by analyzing chlorophyll levels.

Gentle Handling: A well-designed transport system minimizes damage to delicate peppers.

This peppers sorting machine is the ideal choice for farms that supply premium markets where cosmetic perfection is non-negotiable.

The CDS Manufacturing OptiSort-P5 is engineered for unparalleled accuracy in color and size grading. This machine is perfect for operations that need to sort peppers into multiple specific grades for different buyers. It ensures consistency across thousands of units, which is critical for meeting strict retail and food service contracts.

The OptiSort-P5 employs high-resolution color cameras and infrared (IR) imaging. This combination allows it to grade peppers based on subtle shade differences and surface texture. Its powerful software processes this data in real-time to sort peppers by length, diameter, and color profile simultaneously. The user-friendly interface allows operators to quickly set or change grading parameters.

| Feature | Specification | Benefit for Farmers |

|---|---|---|

| Camera System | Full-Color & IR Cameras | Sorts by ripeness, color, and size. |

| Grading Lanes | Up to 5 lanes | High sorting capacity for medium-sized farms. |

| Size Accuracy | Within +/- 1mm | Delivers highly uniform product batches. |

| Ejection System | Smart-Jet Air Ejectors | Removes product gently without causing damage. |

Farms needing to fulfill complex orders with precise size and color requirements will find the OptiSort-P5 to be an invaluable asset.

The Hefei Meritech CS-3000 delivers reliable sorting performance without a premium price tag. It is an excellent entry-point into automated sorting for medium-sized farms looking to improve efficiency and reduce labor costs. This model balances essential sorting capabilities with a low total cost of ownership.

The CS-3000 uses standard high-definition color cameras and straightforward sorting logic. While it may not have the advanced 3D or IR capabilities of pricier models, it effectively sorts peppers by primary color and identifies major defects like rot or significant blemishes. Its simple design translates to easier maintenance and lower power consumption, further reducing operational expenses.

📝 Note: The CS-3000's value proposition is its rapid return on investment (ROI). The savings on manual labor costs often allow the machine to pay for itself much faster than more complex, high-end sorters.

This machine is the top choice for growers who need to automate their sorting process to increase throughput and consistency on a limited budget.

The Agro-Tech VersaSorter 4X lives up to its name by offering exceptional flexibility. Many farms grow more than one type of pepper, from sweet bells to spicy jalapeños. This peppers sorting machine is designed to handle that diversity with minimal downtime for changeovers.

Its key feature is an adjustable conveyor and camera system. Operators can easily modify the machine's physical and software settings to accommodate different pepper shapes and sizes. The software comes with pre-loaded profiles for common pepper varieties, but users can also create and save custom profiles for unique crops.

Handles a Wide Variety of Peppers:

Bell Peppers (all colors)

Jalapeños and Serranos

Habaneros and Scotch Bonnets

Anaheim and Poblano Peppers

Mini Sweet Peppers

The VersaSorter 4X is the ultimate solution for farms with diverse crop portfolios. Its adaptability ensures that one machine can meet sorting needs across multiple product lines, maximizing its utility throughout the entire growing season.

When speed and volume are the top priorities, the GI AGRO FlowMaster 5000 leads the pack. This machine is built for large medium-sized farms or operations nearing large-scale production. It is designed to process a massive quantity of peppers per hour, making it a critical tool for getting products out of the field and onto trucks quickly.

The FlowMaster 5000 achieves its high throughput with a wide conveyor belt and an array of cameras and ejectors working in parallel. It can process up to 10 tons of peppers per hour, depending on the product size. While its primary function is rapid bulk sorting for color and major defects, it maintains a high level of accuracy even at top speed.

🚀 Pro Tip: Pair the FlowMaster 5000 with efficient infeed and outfeed systems to maximize its performance. A bottleneck before or after the sorter will prevent you from reaching its full throughput potential.

For farms where every hour of processing time counts, the FlowMaster 5000 is the undisputed champion of high-volume sorting.

Selecting the ideal equipment involves more than just comparing prices. A farm must evaluate its specific operational needs, product quality standards, and workforce capabilities. A thorough analysis of these areas ensures the chosen peppers sorting machine delivers a strong return on investment.

Before investing, farm managers should consider several critical factors. These elements directly impact which sorter will best fit their operation.

Primary Sorting Goal: Determine the main objective. Is it removing defects like rot and blemishes? Or is it precise grading by color, size, and density for different buyers? Your priority dictates the necessary technology.

Harvest Volume: Calculate your average and peak hourly throughput needs. This helps match your farm's output with a machine's processing capacity, preventing bottlenecks.

Crop Diversity: Farms growing multiple pepper varieties need a flexible machine. A sorter with adjustable settings and custom profiles offers greater long-term value.

Operator Skill Level: Assess your team's technical proficiency. Advanced sorters require operators with mechanical knowledge for calibration, maintenance, and troubleshooting. Simpler models may be better for teams with less technical experience.

💡 Pro Tip: A machine's effectiveness depends on the operator. Ensure your staff has the problem-solving abilities to manage the equipment efficiently and minimize downtime.

This table provides a side-by-side look at the top models based on the key factors. Use it to quickly compare how each machine aligns with your farm's needs.

| Model | Best For | Throughput | Key Technology | Operator Skill Level |

|---|---|---|---|---|

| Raytec Dryce | Defect Detection | Moderate | 3D Lasers & Decaray | High |

| CDS OptiSort-P5 | Precision Grading | Moderate-High | Color & IR Cameras | Moderate |

| Meritech CS-3000 | Budget Operations | Moderate | HD Color Cameras | Low-Moderate |

| Agro-Tech 4X | Versatility | Moderate | Adjustable Conveyors | Moderate |

| GI AGRO 5000 | High Volume | Very High | Parallel Processing | Moderate-High |

An automated pepper sorter is a significant capital expense. Farm owners must analyze its potential return on investment (ROI) before purchasing. A strong ROI comes from reduced labor costs, manageable operating expenses, and increased product value. A careful evaluation of these three areas will clarify the financial benefits of automation.

Automating the sorting process directly reduces the need for manual labor. Calculating these savings is a crucial first step in understanding a machine's financial impact. Farm managers can estimate their annual savings with a straightforward approach.

Determine Workers Replaced: Identify the number of manual sorters the machine will replace.

Calculate Annual Wages: Multiply the number of workers by their average annual salary, including benefits and insurance.

Estimate Net Savings: The resulting figure represents the gross annual labor savings.

For example, replacing five seasonal workers who each earn $20,000 per season yields an annual labor saving of $100,000. This figure forms the foundation of the ROI calculation.

A sorter's total cost of ownership extends beyond its initial price. Farms must account for ongoing maintenance, potential repairs, and energy consumption. These operational expenses will slightly offset the labor savings. However, various programs can help manage these costs.

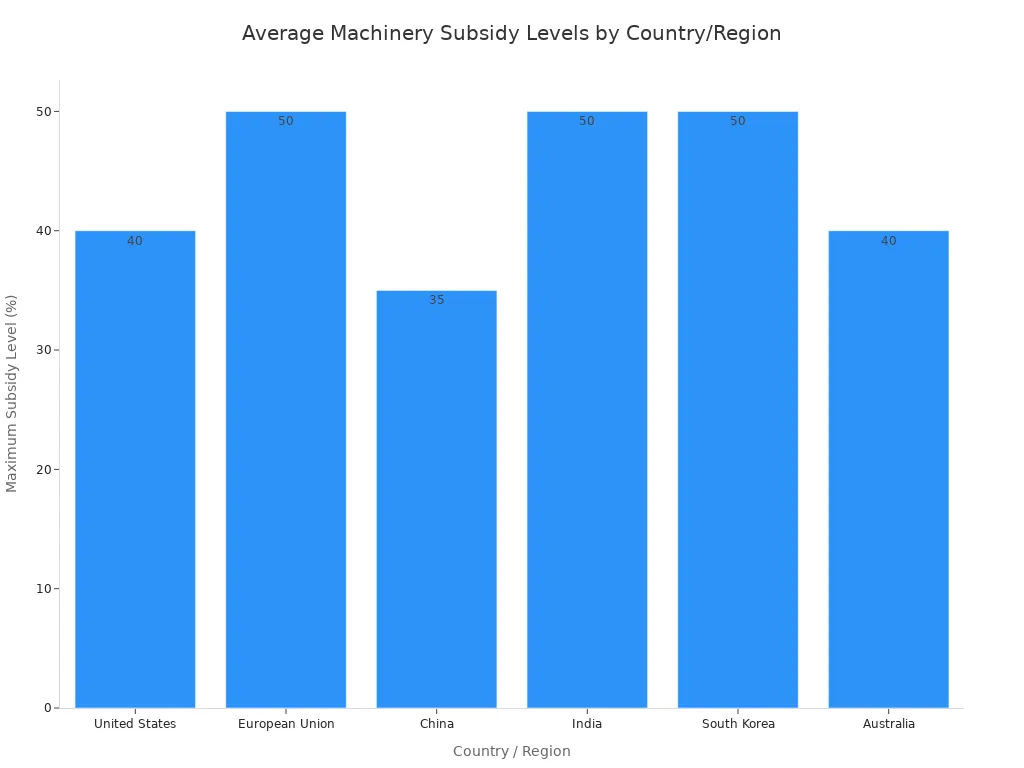

📝 Note: Governments worldwide offer financial incentives to help farms modernize. Many programs provide subsidized loans or grants that can cover a significant portion of the equipment's cost, making the investment more accessible.

These policies often support the adoption of sustainable and efficient technologies, which aligns perfectly with modern sorting equipment.

A high-quality sorter boosts revenue by ensuring the final product meets stringent quality standards. This consistency allows farms to access premium markets and command higher prices. Sorters accurately grade peppers based on official standards.

U.S. Fancy: Peppers are mature, firm, well-shaped, and free from defects.

U.S. No. 1: Peppers are mature, firm, fairly well-shaped, and free from significant damage.

U.S. No. 2: Peppers are mature, firm, and free from serious defects or damage.

Meeting the "U.S. Fancy" grade consistently can significantly increase the price per pound. Financial support from government programs further justifies this investment in quality.

For farms prioritizing volume, the GI AGRO FlowMaster 5000 is the clear winner. Operations on a tighter budget will find the Hefei Meritech CS-3000 offers the best value. If precision is the primary goal, the Raytec Vision Dryce delivers unmatched accuracy. Farms should assess their needs to select the ideal peppers sorting machine, as future trends favor AI integration and sustainability.

Most sorters need daily cleaning and weekly calibration. Manufacturers also recommend annual professional servicing. This proactive approach prevents major downtime and ensures the machine's longevity.

Some models are designed only for dry produce. Farms must confirm a machine's specifications before purchase. Processing wet peppers on an unsuitable sorter can cause errors and damage.

A well-maintained pepper sorter typically lasts 10 to 15 years. The lifespan depends on usage intensity, maintenance quality, and the technological relevance of its software and hardware.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Recommedation: Chili, walnut, peanuts, soybeans, c...

Recommedation: Chili, walnut, peanuts, soybeans, c...

Chicken bone inspection, global poultry AI databas...

Recommedation: Frozen vegetables such as green be...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Advanced nut sorting machine technology combines H...

MoreOptical sorting technology has become indispensabl...

MoreX-ray inspection machines have become indispensabl...

MoreFor processors, the challenge is evolving. It is n...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Farm ManagerThis pepper sorting machine has revolutionized our harvesting process. The accuracy in grading by size and color is remarkable, and it processes peppers three times faster than manual sorting. A game-changer for our farm!

Sarah Chen

Food Processing Plant SupervisorHighly efficient machine that significantly reduced our labor costs. The automatic defect detection works well for spotting bruised or discolored peppers. Minor calibration needed initially, but overall excellent performance.

James Wilson

Quality Control SpecialistThe optical sorting technology is incredibly precise. It consistently identifies and separates peppers by quality grades with 98% accuracy. The user interface is intuitive, and maintenance requirements are minimal.

Emily Thompson

Packaging Facility OwnerOutstanding machine that streamlined our entire packaging line. The gentle handling prevents damage to delicate peppers, and the customizable sorting parameters allow us to meet different client specifications effortlessly.