Pharmaceuticals

Pharmaceutical inspection is widely used to detect contaminants, defects, and packaging issues. This process safeguards consumers and maintains consistency across tablets, capsules, powders, and packaged medications.

REQUEST A QUOTE

Capabilities

-

Safety: Contaminant Detection

In pharmaceuticals, foreign matter contamination threatens patient safety and harms brand reputation. Metals, glass, plastics, or SUS sieve mesh wire can enter products through equipment wear, raw material contamination, or improper handling. Timely detection and removal are essential to ensure compliance with strict industry standards.

Advanced X-Ray technology provides fast, precise contaminant detection and real-time removal of non-compliant products. It enhances efficiency, maintains consistent drug quality, and helps prevent recalls—safeguarding patient safety, protecting brand reputation, and giving pharmaceutical companies reliable assurance of product quality and safety. -

Quality Upgrade

The pharmaceutical industry requires drugs to be safe, accurate, and reliably delivered. X-Ray and visual inspections ensure quality at every production stage, detecting defects such as damage, cracks, breakage, or clumping. They monitor packaging in real time, identifying filling gaps, missing components, packaging abnormalities, or labeling errors, while ensuring accurate filling volumes and intact seals to prevent leakage.

These technologies enable comprehensive quality control, improve production efficiency, reduce recall risks, and ensure that every drug consistently meets the highest standards of safety and quality. -

Driving Long-Term Success

Pharmaceutical quality standards are exceptionally strict, as any flaw can directly impact patient health. Foreign object detection is essential to ensure drug purity, prevent contamination, and maintain therapeutic effectiveness. Comprehensive quality control ensures dosage accuracy, stability, and efficacy meet rigorous standards. Tablet integrity, precise filling, secure packaging, and accurate labeling are also crucial to prevent misuse and ensure safety.

To achieve this, the pharmaceutical industry must uphold the highest safety and quality standards in full compliance with GMP and FDA regulations. Continuous inspection and verification throughout production help safeguard patient health, ensure consistent product reliability, and strengthen brand reputation in this highly regulated industry.

whole chain solution

Pharmaceuticals

• Sieve Mesh Wires

• Metals, Stones, Plastics, Glass

• Damages, Breaks, Cracks

• Missing/Empty Tablets

• Seal Clip

• Clumping

• Filling Capacity

• Deformed Packages

• Vacuum Detection

Industrial Applications

Explore by industry - access for more information.

-

Tablets/Capsules

More information -

Bottled Medicine

More information -

Bottled Liquid

More information -

Injection Bottles

More information

Get in Touch!

For your pharmaceuticals inspection & sorting solutions!

Contact

For your pharmaceuticals inspection & sorting solutions!

Related Machines

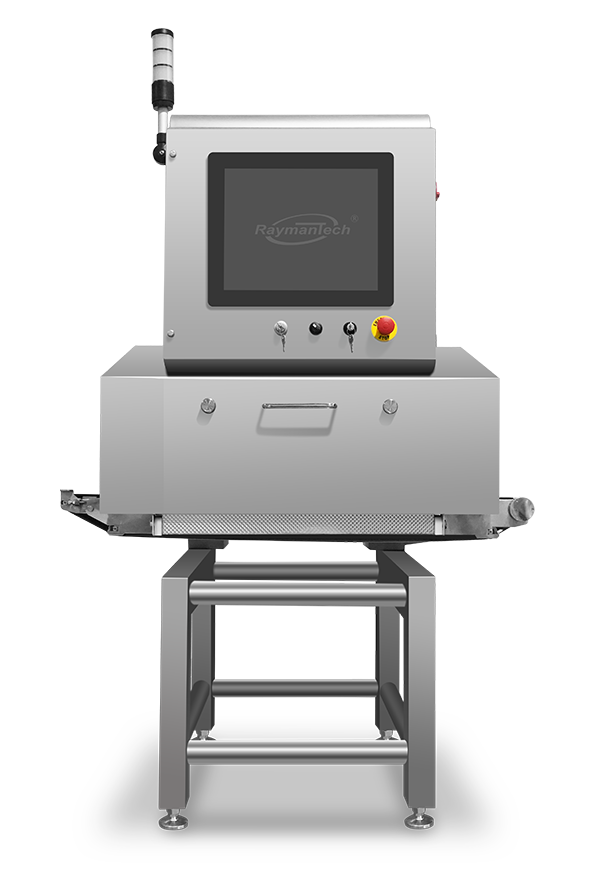

X-Ray Inspection Systems

Optical Sorting Systems

-

AI X-Ray

Contaminant identification

Defect detection

Seal inspection

Real-time data processing

-

Compact Economical X-Ray

AI-powered high resolution detector

IP67 for Inspection tunnel

IP69K full body optional

Defect and missing inspection

-

UHD X-Ray System

AI-powered UHD detector technology

Adaptable resolution technology

Ultra-fine contaminant inspection

IP67 for inspection tunnel

-

AI Medium Speed Sorter

.png)

Contaminants and defects sorting

Tiny impurity (hair) sorting

For wet and high-dust environments

For fragile or delicate products

-

AI Multi Beam Sorter

For dry/wet/frozen materials

Multi-view imaging

-

AI Top View Sorter

For small particles/flat products

Top single, double, or triple view

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

© 2015-2025 RaymanTech - Privacy Policy - Term of Use