Comprehensive Introduction to IP69K Protection Rating — The Gold Standard for Equipment in Meat and Food Processing Environments

Why do IP65/IP67 fail in food plants? Discover the...

More

Foreign material contamination prompted numerous 2024-2025 food recalls, from plastic in sausage to metal fragments in ground beef. Producers deploy a portable x ray inspection system for food to prevent these physical hazards. The top-performing systems for 2025 are:

Mettler-Toledo X34c Compact

Anritsu XR75 PortaSpect

Eagle PI Pack 240p

Sesotec RAYCON D+ Mobile

Mekitec MEKI-C

Ishida IX-G2-F

Loma Systems X5-C Compact

Modern food production facilities are dynamic environments. A fixed inspection point is no longer sufficient. Portability offers the flexibility needed to uphold safety standards across multiple lines and changing workflows. Mobile systems empower quality assurance teams to respond swiftly to emerging risks.

Mobile inspection units provide significant operational benefits. Their designs simplify transport and positioning, even in confined spaces. This allows producers to bring advanced inspection capabilities directly to various points on the production floor.

Versatile Deployment: A single unit can serve multiple production lines, reducing equipment costs.

Point-of-Need Inspection: Operators can perform checks at critical control points without disrupting product flow.

Increased Efficiency: Faster setup and acquisition times mean less downtime and higher throughput.

Note: This flexibility is crucial for facilities running seasonal products or frequent line changeovers, maximizing the return on investment.

A modern portable x ray inspection system for food identifies a wide range of physical hazards that metal detectors miss. These systems excel at finding dense foreign bodies inside packaged goods. They reliably detect contaminants including:

Metals: Ferrous, non-ferrous, and even non-magnetic stainless steel fragments.

Glass: Shards of glass and mineral stones.

Dense Plastics: Pieces of PVC, rubber, and other high-density polymers.

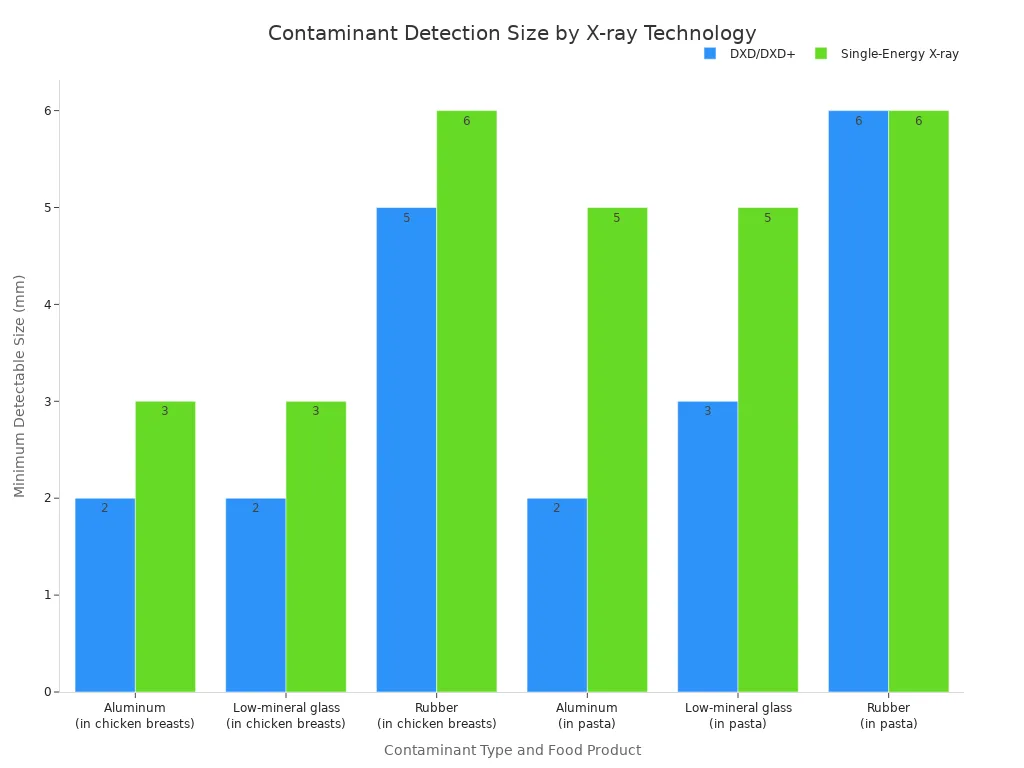

Advanced technologies enhance detection sensitivity, allowing systems to spot smaller contaminants in various food matrices.

Global food safety standards are becoming more stringent. Regulations under the Food Safety Modernization Act (FSMA) require proactive hazard prevention. A portable x ray inspection system for food is a powerful tool for compliance. It enables robust verification for a company's Hazard Analysis and Critical Control Points (HACCP) plan. Deploying these systems helps producers demonstrate due diligence. It also protects their brand by preventing contaminated products from reaching consumers.

Choosing the right system requires a close look at each model's strengths. The following reviews break down the top contenders for 2025, highlighting their unique features, performance capabilities, and ideal applications. This analysis will help you align a system's benefits with your facility's specific inspection needs.

The Mettler-Toledo X34c Compact is engineered for producers with limited line space who cannot compromise on detection sensitivity. It excels in inspecting small, individually packaged products. Its design combines a minimal footprint with high-performance capabilities, making it a powerful and efficient choice.

Compact Design: The system measures only 700 mm in length, including an integrated reject mechanism, allowing for easy installation into crowded production lines.

High-Speed Operation: It operates at speeds up to 120 meters per minute, keeping pace with demanding throughput requirements.

Precision Detection: An optimized 0.4mm diode detector and a 100W Optimum Power Generator work together to identify very small contaminants.

User-Friendly Software: The system runs on ContamPlus™ software for simple setup and connects to ProdX™ for streamlined data management and traceability.

Durable Construction: It comes with an IP55 rating standard and offers an optional IP65 upgrade for enhanced protection in wash-down environments.

Expert Tip: The X34c's active cooling option makes it a reliable choice for facilities with ambient temperatures below 86 °F (30 °C), ensuring consistent performance.

Anritsu's XR75 PortaSpect prioritizes true mobility and rapid deployment. This unit is built on a wheeled frame with a collapsible conveyor, allowing one person to move and set it up in minutes. Its primary advantage is its ability to serve multiple low-throughput lines or perform spot-checks across a facility. The intuitive interface and simplified calibration process reduce training time and empower operators to conduct inspections with confidence. It is an ideal solution for quality assurance labs or for seasonal producers who need a flexible inspection asset.

The Eagle PI Pack 240p is a versatile workhorse designed for a wide range of packaged food applications. Its key strength lies in its advanced SimulTask™ PRO imaging software, which performs multiple quality checks simultaneously. Beyond contaminant detection, it can verify product weight, check seal integrity, and count components within a package. This multi-faceted inspection capability helps producers enhance quality control and optimize production efficiency. The system's robust build and adaptable software make it suitable for dynamic environments with diverse product types.

The Sesotec RAYCON D+ Mobile offers an excellent balance of performance, mobility, and value. Mounted on a sturdy, hygienic mobile frame, this system can be easily relocated and integrated into various production lines. It features a user-friendly touchscreen interface with image-based navigation, simplifying operation. The RAYCON D+ Mobile is particularly effective for inspecting packaged goods and provides reliable detection of metals, glass, and other dense contaminants. Its hygienic design, with sloped surfaces and minimal crevices, facilitates quick and thorough cleaning, a critical feature for food safety compliance.

The MEKI-C from Mekitec stands out for its extremely small footprint and cost-effectiveness. It is designed as an entry-level portable x ray inspection system for food, perfect for small businesses or as a supplementary unit in larger facilities. Despite its compact size, it delivers reliable detection for basic contaminants in small packaged products. The system's simple software and low power consumption contribute to a low total cost of ownership. Its plug-and-play design ensures it can be operational almost immediately, providing an accessible path to enhanced food safety.

The Ishida IX-G2-F is the specialist for detecting low-density contaminants, particularly bone fragments in poultry and fish. Its effectiveness comes from a sophisticated dual energy sensor system. This technology compares images from two different X-ray energy levels. One level captures the overall product image, while the other specifically targets foreign bodies. This process allows the system to analyze X-ray absorption and isolate contaminants like wishbones, fan bones, and rib bones as small as 2-3mm, which are often missed by standard X-ray machines.

Reliability Data: Ishida guarantees a Total Cost of Ownership (TCO) of less than 3% annually over a five-year period with its service package, underscoring the system's long-term reliability and financial predictability.

The Loma Systems X5-C Compact is engineered for maximum protection in the smallest possible space. At just 1000 mm in length, it is one of the most compact systems available, yet it delivers first-class performance. It is an ideal solution for inspecting retail-packed convenience foods, including ready meals in foil trays.

Detection Range: It reliably finds all metal types, glass, calcified bone, rubber, and stone, even in products packaged with foil or metallized film.

High Throughput: The system can operate at speeds up to 240 packs per minute, making it suitable for high-volume, 24/7 production environments.

Compliance Ready: It helps producers meet strict safety standards, including FSMA, HACCP, and BRCGS.

Built to Survive: A standard IP66 ingress protection rating ensures the system can withstand harsh, high-pressure wash-down procedures.

This combination of a compact footprint, robust construction, and high-speed inspection makes the X5-C a top choice for end-of-line quality control.

Selecting the ideal system involves balancing features, budget, and operational needs. A heavier system, sometimes weighing over 380 kg, may offer a larger inspection area for bigger products. Lighter units provide maximum mobility. A comprehensive portable x ray inspection system for food should align with your specific product types and production environment.

This table provides a high-level overview of the top 7 systems. It highlights their primary strengths and ideal use cases to help you quickly narrow down your options.

| System | Best For | Footprint | Key Feature | Washdown Rating (IP) |

|---|---|---|---|---|

| Mettler-Toledo X34c | High-speed, small packs | Compact (700 mm) | High-speed detection in a small space | IP55 (IP65 optional) |

| Anritsu XR75 PortaSpect | Multi-line spot checks | Mobile Frame | Rapid setup and true mobility | Standard |

| Eagle PI Pack 240p | All-in-one quality control | Standard | SimulTask™ PRO multi-check software | Standard |

| Sesotec RAYCON D+ | Value and hygienic design | Mobile Frame | Easy-to-clean, user-friendly interface | Hygienic Design |

| Mekitec MEKI-C | Small businesses, low cost | Extremely Small | Low total cost of ownership | Standard |

| Ishida IX-G2-F | Bone detection (poultry/fish) | Standard | Dual energy sensor technology | Standard |

| Loma Systems X5-C | High-volume, harsh environments | Compact (1000 mm) | High throughput with superior protection | IP66 |

Investing in a portable x ray inspection system for food requires careful consideration beyond the initial price tag. A strategic approach ensures the chosen system delivers long-term value and robust protection for your brand. This guide outlines key factors to evaluate before making a purchase.

First, producers must clearly define their operational requirements. Analyze the types of products you inspect, their size, and packaging materials. Consider your line speeds and the physical space available in your facility. A system perfect for small, lightweight packages may not suit a line running large, dense products. Matching the machine's capabilities to your specific needs is the foundational step in making a smart investment.

The system's software is its brain. In a fast-paced production environment, a user-friendly interface is critical for success.

Intuitive controls and clear displays reduce the operator learning curve.

They also minimize the risk of costly operational errors.

Many modern systems feature touchscreen interfaces that are easy to clean and operate, even while wearing gloves.

A system with simple setup and effortless status indication empowers your team to perform inspections efficiently and confidently.

The total cost of ownership (TCO) combines the initial investment with the lifecycle costs of running the system. These ongoing expenses are a crucial part of the financial assessment. Running costs include factors like power usage and, if applicable, compressed air or water consumption. Additionally, service costs for preventive maintenance and spare parts are integral to the TCO. Regular service extends the machine's lifespan and ensures your portable x ray inspection system for food operates at peak performance.

The ideal portable x ray inspection system for food depends on your unique operational needs, product type, and budget. Each facility must weigh these factors carefully.

The Mettler-Toledo X34c Compact excels in overall performance. For outstanding value, the Sesotec RAYCON D+ Mobile is a leading choice.

This guide's analysis empowers producers to make a confident investment, strengthening food safety and brand protection.

No. The energy levels are extremely low and do not affect the food's safety, taste, or nutritional value. Food remains perfectly safe for consumers to eat after inspection.

Yes. These systems are fully shielded and feature safety interlocks. They prevent operator exposure to X-rays. All designs comply with strict global radiation safety standards for workplace equipment.

Most modern systems have intuitive interfaces that simplify operation.

Basic training often takes just a few hours.

Manufacturers provide full training to ensure proper and safe use.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Recommedation: Chili, walnut, peanuts, soybeans, c...

Ultra-fine contaminants detection, UHD X-Ray detec...

Recommedation: Rice, wheat, corn, grain, pulses, s...

Recommedation: Aquatic products, pet food, candy, ...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Why do IP65/IP67 fail in food plants? Discover the...

MoreX-ray inspection machines have become indispensabl...

MoreAdvanced nut sorting machine technology combines H...

MoreAs pet owners increasingly view their companions a...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Control ManagerThis portable X-ray system has revolutionized our foreign object detection process. The mobility allows us to inspect products right on the production line, significantly reducing contamination risks.

Sarah Chen

Food Safety InspectorOutstanding detection accuracy for bones, metals and glass fragments. The portable design makes it perfect for spot inspections across multiple facilities without compromising on performance.

David Thompson

Production SupervisorHighly efficient system that integrates seamlessly with our existing workflow. The quick setup and intuitive interface have improved our inspection throughput by 40% while maintaining excellent detection rates.

Jennifer Williams

Research ScientistAs a researcher in food technology, I appreciate the system's precision and reliability. The portability feature is particularly valuable for field studies and temporary production setups.