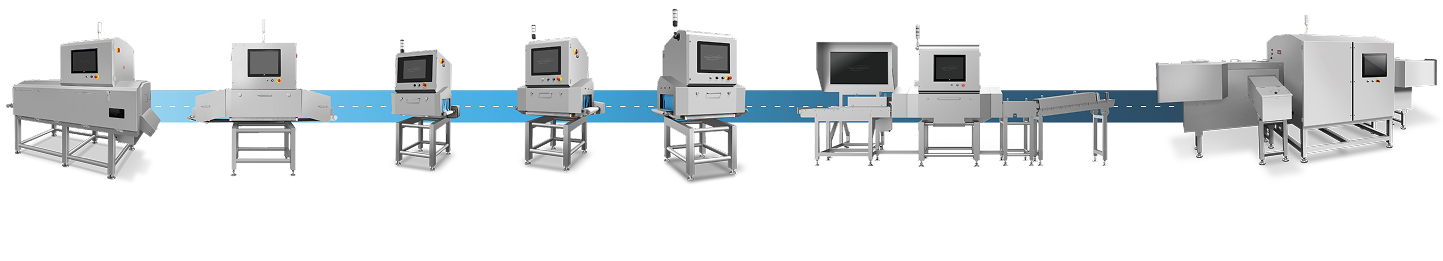

RaymanTech X-ray Inspection Systems: The Complete Guide to a Smarter, Safer Production Line

When a single shard of glass, a fragment of bone, or an unnoticed plastic tie can trigger a multimillion-dollar recall and shatter consumer trust, food manufacturers can no longer rely on yesterday’s detection technology. RaymanTech has built an entire ecosystem of X-ray inspection solutions that go far beyond traditional metal detectors, delivering density-based, shape-aware, AI-enhanced inspection across every product format imaginable.

The RaymanTech X-ray family combines UHD X-ray imaging with high-resolution visible-light cameras and continuously learning artificial intelligence. The result is a detection capability that identifies metal, glass, stone, ceramic, dense plastics, rubber, paper, wood, insects, shells, and even subtle defects like cracks, voids, or color anomalies—regardless of whether the contaminant is metallic or not. RaymanTech X-ray systems see material composition, shape, and context.

Every machine in the lineup shares core design principles that make them production-floor, not laboratory, equipment:

· Ultra-low radiation leakage (<1 μSv/h) meeting the strictest CE and FDA standards

· Full stainless-steel construction with IP65 to IP69K protection for aggressive washdown

· Tool-free belt removal and quick-clean conveyor designs that cut sanitation time by up to 70%

· Modular architecture so spare parts and software updates are shared across the entire series

· Built-in Ethernet, USB, and OPC-UA connectivity for Industry 4.0 integration

The series is intelligently segmented so manufacturers can choose the exact capability their products demand.

For raw materials arriving in bulk—nuts, grains, frozen vegetables, spices, coffee beans—the RXI BHD Series scans at speeds up to 120 m/min while simultaneously sorting by color, shape, and internal defects. Up to 144 precision air jets remove only the defective items, keeping good-product loss under 1%.

When low-density or thin contaminants hide inside overlapping or uneven products—think frozen fries, mixed vegetables, or marinated chicken strips—the Dual Energy lineup takes over. The standard Dual Energy platform, dedicated residual-bone detector for poultry, and specialized fat:lean analyzer deliver material discrimination that single-energy systems simply cannot match. Bone fragments as small as 2 mm in breast fillets or plastic film in frozen blocks become clearly visible.

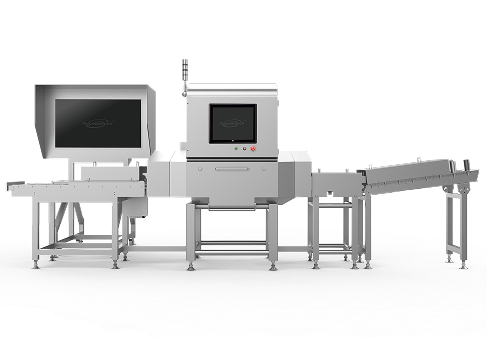

Packaged goods receive equally targeted attention through the Top Down series. Smaller plants choose the space-saving Compact Economical models with 0.4 mm resolution and virtual weighing. Mid-to-high volume lines move to the AI Standard series with automatic defect learning and reject verification. The flagship UHD systems push detection limits to 0.1 mm using TDI line-scan technology, revealing hairline cracks in tablets or microscopic glass splinters in baby food pouches.

Products sealed in bottles, cans, or jars present their own challenges—contaminants can hide at the bottom, under the lid, or inside the neck. RaymanTech answers with the Multi-Beam Bottle & Can series, using one to four X-ray beams to create complete 360° coverage while simultaneously checking fill level, cap presence, and label position at speeds up to 1,200 units per minute.

Seafood processors fighting thin, flexible fish bones that bend with the fillet turn to the dedicated Fish Bone X-ray system, which combines ultra-high-resolution imaging with algorithms trained specifically on salmon, cod, tilapia, and pangasius bone patterns.

Across every model, the same AI engine continuously improves. It learns your product’s normal variation, reduces false rejects over time, and can be retrained on new packaging or recipes in minutes. Data logs every image, every reject reason, and every weight or count measurement for full traceability demanded by BRC, IFS, SQF, and FSMA.

Processors who have made the switch report dramatic results: a major U.S. poultry plant cut bone-related consumer complaints by 92% after installing the residual-bone Dual Energy system. A European snack manufacturer reduced giveaway from overfills by 1.8% using virtual weighing on the Compact series. A global pet-food cannery eliminated glass-in-glass incidents entirely with the four-beam jar inspector.

RaymanTech systems are built in configurations from 180 mm to 800 mm wide, with conveyor speeds from 10 to 120 m/min, and are backed by 24/7 remote diagnostics and a North American spare-parts inventory that ships same-day.

Whether you’re inspecting loose raisins at intake, boneless chicken breasts mid-process, sealed glass jars at high speed, or anything in between, there’s a RaymanTech X-ray solution engineered specifically for the task. Explore the full range at https://www.raymantech.us/x-ray-inspection-systems/ or call 717-490-1513 to discuss which combination of speed, sensitivity, and software intelligence fits your line best.

Related Articles

-

Nov-18-2025

Nov-18-2025RaymanTech X-ray Inspection Systems: The Complete Guide to a Smarter, Safer Production Line

When a single shard of glass, a fragment of bone, or an unnoticed plastic tie can trigger a multimillion-dollar recall and shatter consumer trust, food manufacturers can no longer rely on yesterday’s detection technology. RaymanTech has built an entire ecosystem of X-ray inspection solutions that go far beyond traditional metal detectors, delivering density-based, shape-aware, AI-enhanced inspection across every product format imaginable.learn more -

Nov-18-2025

Nov-18-2025Introduction to RaymanTech Optical Sorters for Farm Products and Food Processors

RaymanTech, as a leading provider of inspection and sorting solutions, has developed a comprehensive optical sorter portfolio that now serves both farm-product applications and food-processing environments. While farm-product sorters focus on capacity, adaptability, and raw-material variability, food-processor-grade sorters must also incorporate high IP protection, robust stainless-steel construction, sanitary design, and harsh washdown compatibility.learn more -

Nov-18-2025

Top 5 Residual Bone Inspection Solution Providers in 2025

This article explores the fundamentals of residual bone inspection, examines market dynamics and technological evolution, and ranks the top five solution providers, highlighting RaymanTech's pioneering leadership.learn more

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057