Seafood Industry

RaymanTech offers inspection and sorting solutions tailored for the seafood industry, applicable to fresh and frozen seafood in both bulk and packaged forms. With X-Ray, metal detection, weight checking and optical technologies, RaymanTech ensures contaminant-free, high-quality seafood products.

REQUEST A QUOTE

Capabilities

-

Safety: Contaminants & Bones

In seafood processing, common contaminants include metal, glass, and stones—often caused by fishing gear or processing equipment wear, packaging breakage, or incomplete cleaning during transport. Natural residues such as fish bones and shell fragments also present ongoing safety risks.

AI UHD X-Ray inspection systems accurately detect and remove these contaminants, ensuring food safety, and minimizing complaints and product returns. With real-time monitoring and data analysis, X-Ray technology streamlines production, enhances traceability, boosts efficiency, reduces manual inspection costs, and ensures full regulatory compliance. -

Quality Upgrade

Seafood such as shrimp and clam meat can become damaged or discolored during transportation or storage, affecting both taste and quality. Residual shell fragments from shellfish processing and seaweed impurities—often difficult to fully remove—can also compromise product hygiene and consistency.

AI X-Ray inspection and AI optical sorting technologies precisely detect and remove foreign contaminants, shell fragments, discoloration, damage, and irregular shapes in shrimp, clam meat, shellfish, and seaweed. By automating sorting and inspection, these technologies reduce manual labor, lower costs, minimize raw material waste, and enhance overall product quality and brand competitiveness. -

Fish Bone Detection

Residual fish bones are a persistent challenge in the seafood industry. Mechanical cutting, raw material variations, fish structure differences, manual handling, equipment wear, or improper adjustments can all result in bones being left behind.

Advanced X-Ray detection precisely identifies even the smallest bones, reducing manual intervention and over-processing. This end-to-end solution ensures the safety of boneless fish products, maintains consistent quality, minimizes consumer complaints, and builds brand trust. At the same time, it improves production efficiency and helps seafood processors better control costs.

whole chain solution

Seafood Industry

• Fish Bones

• Metal Contaminants

• Glass, Stones, Twigs, Ceramics

• Shell Fragments

• Sediment

• Cartilage Inside Lobsters

• Defective Seafood

• Seal Clip

• Canned Seafood

Industrial Applications

Explore by industry - access for more information.

-

Salmon

More information -

Cod

More information -

Shrimp/Prawn

More information -

Lobster

More information -

Clams/Scallops

More information -

Canned Tuna/Sardine

More information -

Vacuum-packed Fish

More information -

Fish Fillets

More information

Get in Touch!

For your seafood inspection & sorting solutions!

Contact

For your seafood inspection & sorting solutions!

Related Machines

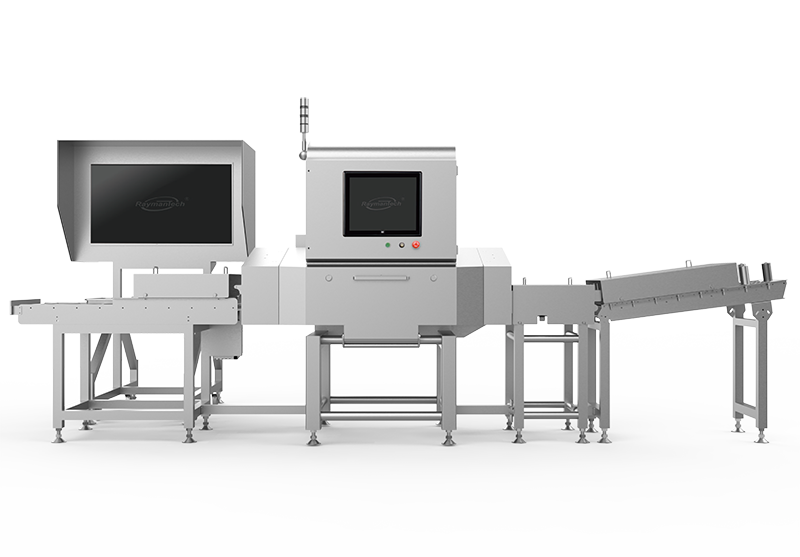

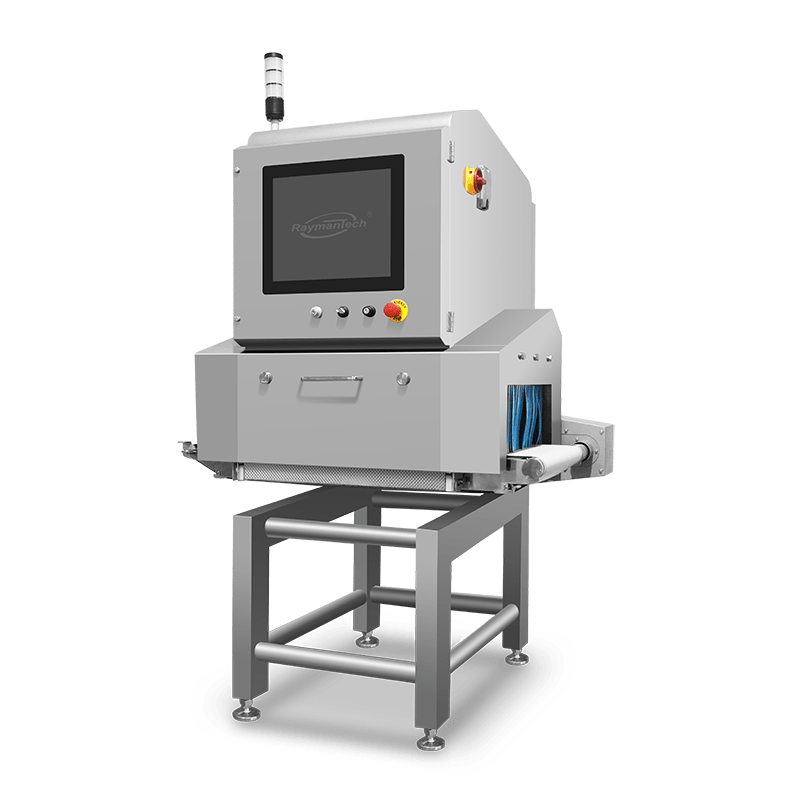

X-Ray Inspection Systems

Optical Sorting Systems

-

X-Ray for Fish Bone

Fish bone inspection

AI powered UHD detector

Tiny contaminant inspection

Auto recognition, auto rejection

-

X-Ray for Can Bottle Jar

.png)

Metal in metal detection

Glass in glass detection

Filling level detection

Full area container detection

-

AI X-Ray

Contaminant identification

Defect detection

Seal inspection

Real-time data processing

-

AI Multi Beam Sorter

For dry/wet/frozen materials

Multi-view imaging

-

AI Medium Speed Sorter

.png)

Contaminants and defects sorting

Tiny impurity (hair) sorting

For wet and high-dust environments

For fragile or delicate products

-

AI Top View Sorter

For small particles/flat products

Top single, double, or triple view

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

© 2015-2025 RaymanTech - Privacy Policy - Term of Use