RaymanTech Whole-Chain Solution: A Deep Dive

Food safety and quality control demands have evolv...

More

X-ray inspection technology excels at removing dense, hazardous contaminants like shell fragments, stones, and metal. A shellfish optical sorter effectively manages surface-level quality, sorting products by color or size.

Note: The right choice depends on a processor's primary goal: ensuring safety from hard contaminants or improving aesthetic product quality.

Understanding what each technology can and cannot detect is crucial for selecting the right system. X-ray inspection and optical sorting operate on fundamentally different principles, giving them distinct strengths in a shellfish processing line.

X-ray inspection systems function by identifying differences in material density. The system passes an X-ray beam through the shellfish product. Denser materials absorb more of this energy. This creates a darker signature on a grayscale image, allowing the system to pinpoint foreign bodies hidden from view. The accuracy of detection directly relates to the density contrast between the contaminant and the shellfish meat.

This technology excels at finding dense, hazardous contaminants that pose a significant food safety risk. Advanced systems like the Ishida IX-G2 Series can even detect very small or thin low-density contaminants like bone and shell. Processors rely on X-ray inspection to remove:

Metallic Contaminants: Ferrous metals (iron, steel), non-ferrous metals (aluminum, brass), and even fragments within foil packaging.

Non-Metallic Contaminants: Glass shards, stones, calcified bone, and dense plastics from broken equipment.

Other Dense Materials: High-density rubber fragments.

However, X-ray technology has limitations. It struggles to identify low-density materials that have a similar density to the shellfish itself. These challenging contaminants include:

Wood fragments

Human hair

Thin plastics

Note: Advanced dual-energy X-ray systems improve the detection of some low-density contaminants. These machines analyze products at multiple energy levels, enhancing their ability to distinguish subtle density differences.

Optical sorters act as a set of powerful, automated eyes. These systems use high-resolution cameras and intelligent software to analyze the surface of each item. They make decisions based on visual attributes like color, size, shape, and texture. This technology is essential for grading products and removing aesthetic imperfections.

A shellfish optical sorter employs machine vision and AI algorithms to ensure consistent product quality. For example, these systems perform "cold shrimp sorting" by separating shrimp based on color and size while removing broken pieces. For oysters, shape analysis methods like Turn Angle Cross-Correlation (TAC) can categorize products into grades such as "good quality" or "irregular" based on their contour.

Optical sorters are highly effective at identifying and removing:

Products with discoloration or stains

Broken or damaged shells

Incorrectly sized or shaped items

Some foreign organic material (e.g., seaweed with a distinct color)

The primary function of optical sorting is to improve product quality and uniformity by judging items based on their external appearance. It ensures the final product meets the aesthetic standards consumers expect.

While X-ray inspection focuses on safety, a shellfish optical sorter prioritizes product quality and uniformity. Understanding its specific function, technology, and inherent limitations helps processors deploy it effectively.

The primary function of an optical sorter is to analyze and sort products based on external features. These systems use high-resolution cameras and lighting to capture images of each item on the processing line. Advanced software then analyzes these images in real-time.

Optical sorters detect surface-level characteristics such as color, shape, or variations in moisture. This allows them to remove foreign materials or items that do not meet quality parameters. Processors configure these parameters to fit specific product standards. The machine then ejects any item that fails to meet the preset criteria for size, color, or shape.

Key Takeaway: Optical sorters make decisions based on what they can "see" on the product's surface, acting as an automated quality control inspector.

The main strength of optical sorting is its ability to enhance aesthetic quality and product consistency at high speeds. It excels at grading products and removing items with surface defects. However, its greatest limitation is its inability to detect internal contaminants.

A simple comparison highlights where each technology performs best:

| Technology | Best For |

|---|---|

| Vision Sorting (Optical) | Surface defects, color variations, plastic |

| X-Ray Inspection | Bone, glass, metal, internal contaminants |

An optical sorter cannot identify a stone or shell fragment hidden within shellfish tissue because these contaminants are not visible on the surface. This makes the technology unsuitable as a primary defense against dense, hazardous foreign bodies. It is a tool for quality, not a comprehensive safety solution for internal risks.

Beyond detection capabilities, processors must evaluate how each system impacts daily operations. Factors like line speed, cost, and maintenance protocols play a significant role in determining the best fit for a shellfish processing facility.

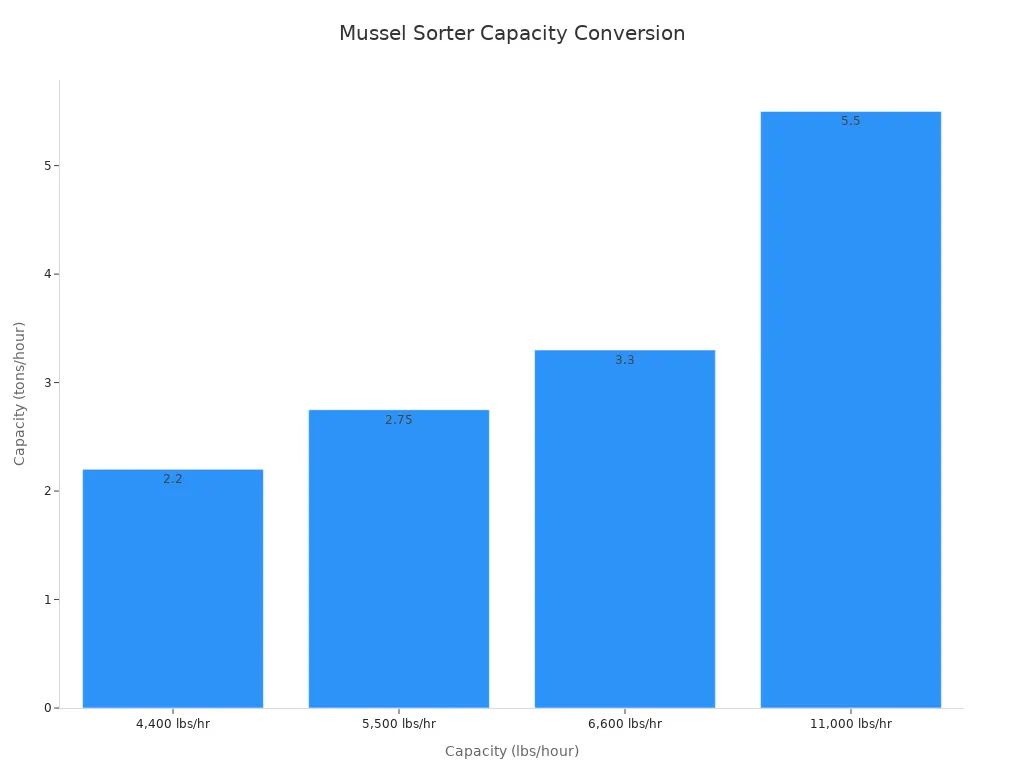

Both X-ray and optical systems are engineered for high-speed processing lines to avoid becoming a bottleneck. Optical sorters are particularly notable for their rapid sorting and grading capabilities. For example, some dedicated mussel sorters can process up to 35 pieces per second. High-capacity optical sorters for mussels and clams can handle significant volume, as shown by their capacity conversions from pounds to tons per hour.

X-ray systems, including bulk-flow models for shrimp and scallops, also maintain high throughput while performing complex density analysis.

Cost is a primary consideration. X-ray inspection systems represent a significant capital investment, as they are complex machines designed for critical safety. Economical X-ray systems start around $38,000, but the price increases with advanced software, larger sizes, and washdown-ready construction. In contrast, optical sorters generally have a lower upfront cost. However, processors should evaluate the total cost of ownership, which includes maintenance, energy use, and potential returns from improved product quality or prevented recalls.

Routine maintenance for an optical sorter is straightforward. It typically involves:

Cleaning camera lenses and lighting

Inspecting parts for wear and tear

Calibrating sensors for accuracy

X-ray systems demand more rigorous safety protocols. Due to the use of radiation, facilities must implement a written Radiation Protection Program (RPP) to comply with regulations. Furthermore, operators require specialized safety training and certification. This ensures they can operate the equipment safely and maintain full compliance with federal and state standards, protecting both workers and the integrity of the food safety program.

Choosing the right inspection technology requires a clear understanding of your product's specific risks and quality goals. This guide outlines practical scenarios to help processors determine the most effective solution for their production line.

Processors must prioritize X-ray inspection when the primary goal is eliminating dense, hazardous contaminants that pose a direct threat to consumer safety. This technology is essential for products where foreign bodies can become hidden within the meat or packaging. X-ray inspection becomes the critical control point in these situations.

Consider X-ray inspection essential for:

Heavily Processed Products: Operations like deshelling, breading, or canning introduce multiple opportunities for contamination from machinery or handling.

High-Risk Raw Materials: Shellfish harvested from areas with rocky or sandy seabeds have a higher likelihood of containing stones or shell fragments.

Final Package Inspection: An X-ray system can inspect the final sealed product, detecting contaminants introduced at any stage, including packaging.

Research shows that processing significantly increases contamination risks. For example, studies on microplastics reveal how post-harvest handling introduces foreign material.

| Shellfish Product Type | Microplastic Contamination Level (items) |

|---|---|

| Deep-frozen deshelled clams (DFC) | 113.33 ± 1.53 to 252.33 ± 142.78 |

| Ready-to-cook frozen with shell (FC) | 55.67 ± 16.74 to 89.33 ± 60.28 |

Note: While X-ray systems do not detect microplastics, this data illustrates a critical point: processed shellfish, like deshelled clams, are far more susceptible to contaminants introduced during handling. An X-ray system is the only reliable method to find dense fragments of shell, metal, or glass that may enter the product during these stages.

An optical sorter is the best choice when the primary objective is to enhance product quality, improve grade consistency, and increase profitability. This technology excels at analyzing surface characteristics, making it a powerful tool for automated quality control. It is ideal for processors aiming to deliver a visually appealing and uniform product to the market.

A shellfish optical sorter drives value in several key ways:

Accurate Sorting and Grading: It can rapidly sort products like shrimp, scallops, and oysters by size, color, and shape, creating premium grades that command higher prices.

Defect Removal: The system identifies and ejects items with discoloration, broken pieces, or surface blemishes, ensuring only top-quality products reach the consumer.

Foreign Material Removal: It effectively removes low-density organic matter that X-rays cannot see, such as seaweed, bycatch, insects, or even paint flakes from machinery.

Reduced Labor Costs: Automating the sorting process leads to faster production speeds and significantly lowers the reliance on manual labor for quality checks.

This technology is particularly effective for products where appearance is directly linked to value, such as fresh oysters, packaged shrimp, or prepared mussels.

| Feature | Vision / Optical Sorting Machine |

|---|---|

| Main Function | Sorts by appearance & quality |

| Technology | Cameras + AI sensors |

| Purpose | Quality + defect detection |

| Best For | High-profit quality selection |

For processors seeking the highest standards of both safety and quality, the dual-system strategy is the ultimate solution. This approach combines the strengths of both technologies to create a comprehensive inspection process that leaves no stone unturned—literally. An optical sorter first refines product quality, and an X-ray system then provides the final, critical safety check.

Implementing a dual system offers a powerful return on investment (ROI) through comprehensive risk mitigation. While a direct comparative analysis is complex, the value is clear. Advanced inspection systems are three to five times faster than manual methods, drastically reducing labor costs and false rejections.

Key Advantage: The primary ROI of a dual system comes from protecting your brand. It prevents costly recalls, safeguards brand reputation, and avoids expensive liability lawsuits by ensuring the final product is free of both aesthetic defects and hidden physical hazards.

This layered defense works sequentially:

Optical Sorter: The product first passes through the optical sorter, which removes discolored items, broken pieces, and low-density foreign material like seaweed. This step perfects the product's grade and appearance.

X-Ray Inspection: The graded product then moves to the X-ray system. This machine scans for dense internal contaminants like metal, glass, and shell fragments, ensuring the aesthetically pleasing product is also safe to eat.

This strategy guarantees a final product that meets the highest expectations for both consumer safety and market quality.

Processors must prioritize X-ray inspection for critical food safety, as it is the essential tool for eliminating dense internal contaminants. A shellfish optical sorter offers a cost-effective method for enhancing product quality and grading. For the highest standards, a dual-system strategy combining both technologies provides the ultimate solution.

An optical sorter analyzes surface appearance for quality control. An X-ray system detects internal, dense contaminants like shell or metal to ensure food safety.

X-ray inspection is essential for safety. It finds hazardous internal contaminants like shell fragments, metal, and glass that optical sorters cannot see.

No, each system has a distinct purpose. Processors use a dual-system strategy to achieve the highest standards of both product quality and consumer safety.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Recommedation: Chili, walnut, peanuts, soybeans, c...

Automatic recognition and rejection, fish bone ins...

Uneven and overlapped product detection, thin & lo...

UHD X-Ray detector, AI large model, all food indus...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Food safety and quality control demands have evolv...

MoreRaymanTech, as a leading provider of inspection an...

MoreIn the fast-paced world of food production, ensuri...

MoreBone fragments are the poultry industry’s most per...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Production ManagerThis shellfish optical sorter has revolutionized our processing line. The accuracy in identifying and sorting different shellfish species is remarkable, and it has significantly reduced our labor costs while improving throughput.

Sarah Chen

Quality Control SupervisorOutstanding performance! The optical sorter consistently detects and removes defective shellfish with incredible precision. The user-friendly interface makes operation straightforward, and maintenance requirements are minimal.

James Wilson

Plant Operations DirectorHighly efficient system that has improved our sorting accuracy by over 95%. The initial setup was smooth, and the technical support team was very responsive. Minor learning curve for operators, but well worth the investment.

Emily Thompson

Processing EngineerThis optical sorter has exceeded our expectations in every way. The advanced imaging technology handles various shellfish sizes and types flawlessly. Our product quality has never been more consistent, and waste reduction has been substantial.