How a Pistachios Optical Sorting Machine Guarantees Quality and Purity

Pistachios are a premium, high-value commodity. Co...

More

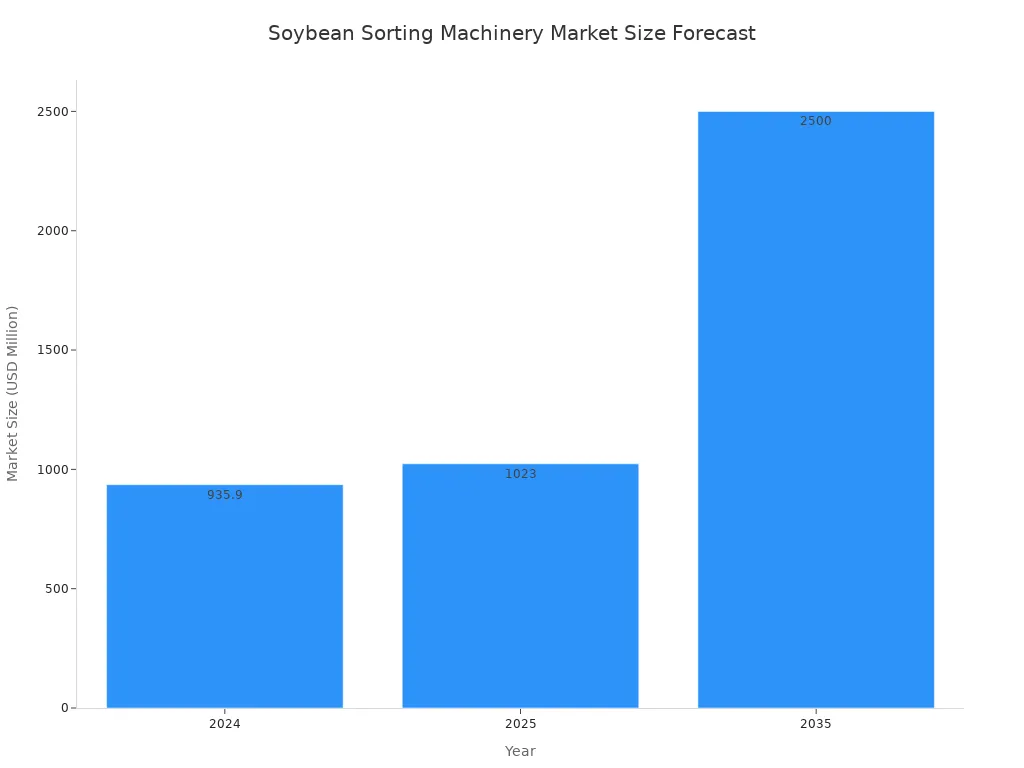

Processors select a soybeans sorting machine based on specific operational goals. A Color Sorter removes discolored beans and foreign materials to enhance product purity. In contrast, a Size Grader separates soybeans into uniform categories for specialized uses like seed or tofu production. This decision grows more critical as market demand for high-quality soybeans accelerates.

Processors choose a color sorter when their primary objective is to elevate product purity and appearance. This machine is the ideal solution for removing visual imperfections and foreign matter. It uses advanced optical technology to ensure each bean meets specific quality criteria, directly impacting the final product's grade and market value.

A color sorter's main function is to identify and eject individual soybeans that fail to meet visual quality standards. The machine uses high-resolution cameras to scan every bean, detecting subtle variations in color and texture that indicate damage. This capability is crucial for creating a uniform, high-quality final product.

A sorter can effectively target a wide range of common defects, including:

Lesions, wrinkling, or cracks appearing on the seed coat

Discoloration caused by diseases or pests

Denatured soybeans (yellow, white, or black)

Peeled or physically damaged samples

By removing these flawed beans, processors protect the integrity and value of their entire batch.

Harvested soybeans often contain a significant amount of foreign material. A color sorter excels at identifying and removing these contaminants from the product stream. Its cameras differentiate the distinct colors and shapes of unwanted materials from healthy soybeans, triggering high-speed air jets to eject them precisely.

Tip: Removing foreign material early in the process prevents damage to other equipment and ensures a safer, purer end product for consumers.

Common contaminants easily removed by a color sorter include weed seeds like pigweed and morningglory, other crop seeds such as corn, and non-organic debris like soil particles, rocks, and stems.

Achieving food-grade certification is essential for accessing premium markets. A modern soybeans sorting machine provides the precision necessary to meet these strict quality and safety standards. Industries producing tofu, soy milk, natto, and other food products demand raw materials free from discoloration, damage, and any foreign matter.

Failing to meet these standards can result in rejected shipments and financial losses. By investing in color sorting technology, processors can consistently produce a clean, safe, and visually appealing product. This consistency builds a strong reputation and opens doors to more lucrative contracts with discerning buyers.

Processors select a size grader when their primary goal is to achieve product uniformity. Unlike a color sorter that focuses on purity, a size grader mechanically separates soybeans into distinct size categories. This machine is essential for operations that need to meet specific processing requirements, optimize seed quality, or target niche markets with strict size specifications. The investment in a size grader directly enhances product consistency and value for specialized applications.

A size grader helps create homogenous batches of soybeans, which is critical for consistent food production. Processors of products like tofu, soy milk, and edamame rely on uniform bean sizes to standardize their manufacturing methods. Beans of the same size absorb water and cook at the same rate. This uniformity prevents issues like undercooked hard beans or overcooked mushy beans in a single batch.

Consistent sizing delivers several key advantages:

Improved Product Texture: Ensures a smooth, even texture in final products like tofu.

Predictable Cooking Times: Allows for precise, repeatable cooking cycles, boosting operational efficiency.

Reduced Product Waste: Minimizes the number of rejected beans that fail to process correctly.

Ultimately, grading for size gives processors greater control over their production line and the quality of their end product.

For agricultural applications, a size grader is an invaluable tool for selecting the best seeds for planting. Seed size is often a direct indicator of its viability and potential vigor. Larger, heavier seeds typically contain more nutrient reserves, which can support stronger initial growth and lead to healthier seedlings.

A soybeans sorting machine that grades by size allows seed producers to isolate the most promising seeds. This practice ensures a higher germination rate and a more uniform crop stand in the field.

| Seed Size | Typical Characteristics | Impact on Planting |

|---|---|---|

| Large | High nutrient reserves, robust embryo | Higher germination rate, stronger seedlings |

| Medium | Average viability | Standard performance, suitable for general use |

| Small/Shriveled | Low nutrient reserves, potential damage | Lower germination rate, weaker plants |

By removing undersized and shriveled seeds, growers maximize their yield potential from the very start of the planting process.

Certain high-value markets demand soybeans that fall within a very narrow size range. A size grader is the only way to consistently meet these precise specifications and access premium pricing. The Japanese market for natto (fermented soybeans) provides a perfect example of this requirement.

For natto, an extra small-sized bean is preferred because you can still see the bean in the final product and “they like the look of a small bean.”

This preference is so ingrained that specific cultivars have been developed to produce smaller seeds. The Japanese soybean cultivar 'Natto-shoryu', for instance, is characterized by its 'small seeds' and has been a foundation for breeding other natto-specific varieties. Buyers in this market categorize beans with exacting detail.

Extra small (gokuko tsubu) and small (kotsubu) sizes are the most popular for natto.

These smaller sizes are preferred because they are easy to eat and pair well with rice.

While medium or large beans are used for different culinary experiences, the overwhelming demand is for smaller beans.

Failing to sort for these specific sizes means a processor cannot enter this lucrative market. A size grader empowers producers to create precisely categorized batches that command higher prices and build a reputation for quality.

Understanding the fundamental distinctions between a color sorter and a size grader is crucial for making an informed investment. These machines operate on different principles to achieve distinct outcomes, directly influencing processing efficiency and final product value.

The core difference lies in their sorting technology. A color sorter is an optical device that uses advanced cameras and sensors to analyze each bean. Modern systems like the Tomra Nimbus BSI+ employ Biometric Signature Identification (BSI) to detect subtle structural and color differences. Others use high-resolution RGB or InGaAs cameras to identify everything from discoloration to foreign materials.

Technology at a Glance:

Color Sorter: Uses high-resolution cameras, optical sensors, and intelligent software to identify defects based on appearance.

Size Grader: Uses mechanical screens (vibrating or rotary) to physically separate beans based on their dimensions.

In contrast, a size grader is a mechanical system. It relies on physical separation using screens, such as rotary or linear vibrating screens. As soybeans pass over these screens, smaller beans fall through the perforations while larger ones continue onward, effectively separating the batch into different size categories.

Each soybeans sorting machine serves a unique primary function. A color sorter’s goal is to achieve purity. It enhances the quality of a batch by identifying and ejecting imperfect beans and foreign contaminants. With deep learning models, these machines can achieve over 90% accuracy in discriminating defects, ensuring the final product is clean, safe, and visually appealing.

A size grader’s objective is to create uniformity. It does not remove discolored beans but instead separates a clean batch into consistent size groups. This function is essential for processors who need to meet specific size requirements for products like tofu or for sorting seeds to optimize planting quality.

Both machines increase the final product's value, but in different ways. A color sorter boosts value by elevating the product's grade and ensuring it meets strict food safety standards. This purification process opens access to premium food-grade markets that pay more for contaminant-free soybeans.

A size grader adds value by enabling processors to meet the precise specifications of niche markets. By creating uniform batches, producers can target lucrative opportunities, such as the market for small-sized natto beans. Both types of machines are built for industrial scale, with many models processing between 2 and 20 tons per hour, ensuring a significant return on investment through enhanced quality and market access.

Making the right choice requires a clear analysis of a processor's specific needs. This checklist helps operators diagnose their primary challenge, define their market, and align their investment with their profit goals.

Processors must first diagnose the core quality issue in their soybean batches. The problem could be contaminants, damaged beans, or inconsistent sizing. Mycotoxin contamination, for example, is a severe threat that requires an effective control strategy.

Mycotoxin prevention management and the processing stage of cleaning and sorting are still the most efficient strategies to control mycotoxin hazards in current feed manufacturing.

Modern diagnostic tools can precisely identify these issues. Processors use these technologies to get a clear picture of their raw material quality.

Near-Infrared (NIR) Spectroscopy: This technology rapidly measures moisture, protein, and fat content.

Deep Learning Models: Systems like the Modified InceptionV3 model can detect and classify defective seeds with over 98% accuracy.

The intended market dictates the necessary quality standards. Soybeans for animal feed have different requirements than those for human consumption. Knowing the end-user is critical.

For Animal Feed: The focus is on high-quality protein and a balanced amino acid profile to improve animal performance.

For Human Consumption: Soybeans must provide a complete protein with all essential amino acids and meet stringent food safety standards for products like tofu and soy milk.

A processor's growth strategy determines the best machine for a return on investment. If the goal is to raise the product grade by removing defects and foreign material, a color sorter is the logical choice. This path opens access to premium food-grade markets. If the strategy is to supply specialized processors or enter niche markets with strict size specifications, a size grader provides the necessary uniformity to command higher prices.

For processors aiming for the absolute highest product quality, the answer is often yes. A single machine solves a specific problem, but a dual-machine system addresses both purity and uniformity. This combined approach is the definitive strategy for producers who want to dominate premium markets and maximize their return on investment. It creates a final product that is visually perfect, contaminant-free, and precisely sized.

A dual-machine system offers comprehensive quality control that neither machine can achieve alone. A size grader creates uniform batches, but it cannot remove discolored or damaged beans. A color sorter removes imperfections, but it cannot categorize beans by size. Using both machines in tandem allows processors to produce soybeans that meet the strictest standards for both appearance and physical dimension. This synergy is essential for creating a product with unparalleled market appeal.

Industry best practice establishes a clear order of operations for maximum efficiency. A size grader is placed before a color sorter in the processing line. This sequence boosts the throughput and accuracy of the entire system.

Pro Tip: Grading for size first creates uniform streams of soybeans. This allows the color sorter to be calibrated more precisely for each size group, improving its defect detection accuracy.

The recommended flow is straightforward:

Raw soybeans enter the size grader for separation.

Sized batches then move to the color sorter for purification.

The final product emerges clean, pure, and uniformly sized.

A dual-system approach unlocks access to the most lucrative segments, such as the premium organic and non-GMO food markets. Buyers in these spaces demand soybeans with superior nutritional profiles, higher protein content, and flawless physical attributes. They expect each bean to meet the highest standards for size, taste, and texture. A combined sorting solution is the only way to consistently meet these multifaceted requirements, ensuring every shipment commands the highest possible price.

Processors must select the right soybeans sorting machine to meet specific quality goals. The decision hinges on the primary problem a facility needs to solve.

Choose a Color Sorter to fix quality issues based on appearance and purity.

Choose a Size Grader to resolve problems related to uniformity and size.

Operators should assess their primary need and market demand to ensure the best return on investment.

Color sorters typically have a higher initial cost. The machine's advanced cameras and software are more complex than the mechanical screens found in a size grader.

Color sorters need specialized care for cameras and ejectors. Size graders require routine checks on screens and motors. Both types demand regular cleaning to ensure optimal performance.

A size grader separates by dimension. It might remove some large debris. It cannot reliably eject contaminants like small stones or discolored beans of a similar size.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Chicken bone inspection, global poultry AI databas...

Recommedation: Aquatic products, pet food, candy, ...

High cost performance, compact design, high sensit...

Recommedation: Frozen vegetables such as green be...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Pistachios are a premium, high-value commodity. Co...

MoreAdvanced nut sorting machine technology combines H...

MoreFor processors, the challenge is evolving. It is n...

MoreX-ray inspection machines have become indispensabl...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Farm ManagerThis soybean sorting machine has revolutionized our harvesting process. The accuracy and speed are incredible, reducing our manual labor by over 70% while maintaining exceptional quality control.

Sarah Chen

Food Processing Plant SupervisorOutstanding performance in our production line. The machine's AI-powered sorting capability consistently identifies and removes defective beans with 99% accuracy. Maintenance is straightforward and downtime is minimal.

James Wilson

Agricultural Equipment SpecialistReliable and efficient machine that delivers consistent results. The customizable sorting parameters allow us to adapt to different soybean varieties. Only minor interface improvements would make it perfect.

Jennifer Martinez

Quality Control ManagerExceptional sorting precision that has significantly improved our product quality. The machine's ability to detect subtle defects and color variations has reduced our rejection rate by 45%. Highly recommended for any serious soybean operation.