Revolutionizing Quality Control with Advanced Hazelnuts Sorting Machines

Advanced nut sorting machine technology combines H...

More

Small businesses face a complex decision when selecting a sunflower seeds optical sorter. Key evaluation criteria include sorting accuracy, throughput capacity, and total cost of ownership.

A business must first define its primary goal—premium quality, budget efficiency, or space conservation—to make a smart investment.

Sorting accuracy directly impacts final product quality. Modern machines achieve this precision using advanced technology. Basic systems use RGB cameras to inspect seeds for visible color and shape defects. More advanced sorters employ infrared, ultraviolet, or hyperspectral imaging. These technologies detect issues invisible to the naked eye, such as chemical composition or internal damage.

Tech Tip: Beyond RGB 💡 Standard RGB cameras can miss subtle defects. Hyperspectral cameras, however, capture data across numerous light bands. This allows the system to identify the unique spectral signature of a healthy seed versus a diseased or damaged one, ensuring superior sorting.

AI and machine learning further enhance a sunflower seeds optical sorter. These intelligent systems learn from sorting decisions, continuously improving their accuracy and efficiency over time.

Throughput measures the volume of seeds a sorter can process, typically in tons per hour. For small businesses, this capacity can range from 0.5 to over 6 tons per hour. A business must balance its production needs with available space. High-throughput machines often require a larger footprint. However, many manufacturers now offer compact models. These space-saving units are lightweight and designed for easy integration into existing workflows, making them ideal for facilities with limited room.

The initial purchase price is only one part of the total investment. A true calculation of Return on Investment (ROI) must include the Total Cost of Ownership (TCO). Business owners should account for ongoing expenses.

Spare parts and consumables

Scheduled maintenance and service

Operator training

Potential downtime risks

Evaluating these long-term costs provides a realistic financial picture. It helps a business choose a machine that is not only effective but also economically sustainable.

Selecting the right machine requires a close look at the top models available. Each offers a unique combination of features tailored to different business priorities. This guide examines five leading sorters to help you find the perfect match for your production goals.

The Bühler SORTEX A stands as the industry benchmark for sorting precision. It is the ideal choice for businesses that prioritize premium product quality above all else. This machine utilizes high-definition InGaAsHD camera technology. This system detects subtle imperfections in color, shape, and material composition that standard cameras often miss.

Key Advantage: Unmatched Purity 🏆 The SORTEX A excels at removing challenging defects like sclerotia, cross-contaminated seeds, and seeds with minimal discoloration. This capability allows producers to meet the strictest quality standards for export or high-end consumer markets.

While it represents a significant upfront investment, its ability to deliver a consistently superior final product provides a strong return for quality-focused brands.

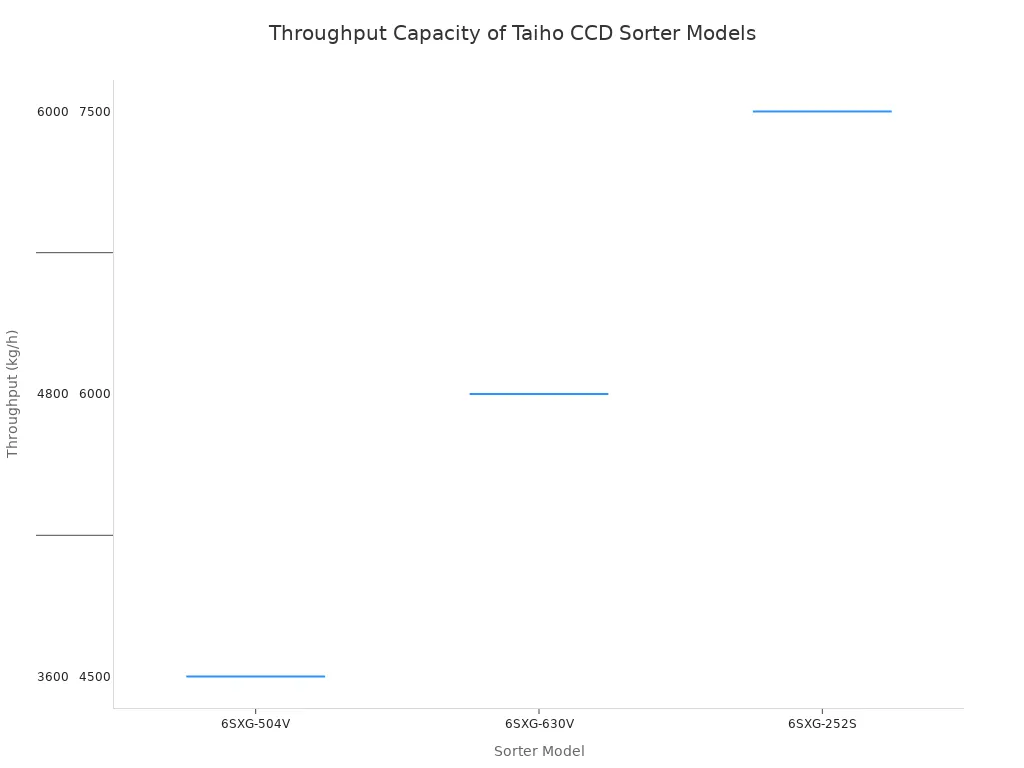

Taiho offers a range of sorters that provide excellent performance at an accessible price point. This makes them a popular choice for small businesses and startups. The Taiho CCD sorter balances cost-effectiveness with reliable sorting accuracy, achieving a rejection rate of over 99% on many models. Its price can range from approximately $5,289 to $66,900, depending on the series and configuration.

This sunflower seeds optical sorter is designed for consistent daily operation. Maintenance requirements are straightforward and predictable.

Routine Care: Cleaning and calibration are typically needed every 200–300 operating hours.

Annual Service: A major servicing is recommended once a year to maintain peak performance.

Taiho provides various models with different throughput capacities, allowing businesses to select a machine that fits their specific production volume.

| Product Series | Model | Throughput (kg/h) |

|---|---|---|

| ZERVI Series | 6SXG-252S | 1200-2000 |

| ZERVI Series | 6SXG-378S | 1800-3000 |

| ZERVI Series | 6SXG-504S | 2400-4000 |

| AI SORT A Series | 6SXG-504V | 3600-6000 |

| AI SORT A Series | 6SXG-630V | 4500-7500 |

For businesses with limited facility space, the Akyurek SORTURK C-5 is an excellent solution. This machine delivers powerful sorting capabilities within a minimal footprint. Its compact design allows for easy integration into existing processing lines without requiring significant facility modifications.

The SORTURK C-5 uses high-resolution cameras and LED lighting to ensure accurate defect removal. It is known for its user-friendly interface, which simplifies operation and reduces the need for extensive operator training. This combination of small size, efficiency, and ease of use makes it a practical choice for small-scale operations looking to automate their quality control.

The TOMRA Nimbus BSI+ is a forward-thinking investment for businesses planning for future growth. Its key feature is its modular design. A company can start with a base model and add advanced sensor modules later as production demands increase. This scalability protects the initial investment and allows the machine to evolve with the business.

The Nimbus uses proprietary Biometric Signature Identification (BSI+) technology. This advanced system goes beyond visual inspection by analyzing the unique biological and chemical properties of each seed.

How BSI+ Works 🔬 BSI+ technology identifies material composition, allowing it to detect:

Mycotoxins like aflatoxin

Differences in moisture content

Internal damage or disease

Foreign materials invisible to the human eye

This powerful sunflower seeds optical sorter can be configured with additional lasers and cameras on a single frame, offering a customized solution for virtually any sorting challenge.

The Satake PELICAN is engineered for durability and reliability. It is an ideal choice for businesses that need a robust machine with minimal downtime. Satake has a long-standing reputation for building high-quality equipment that withstands the rigors of daily industrial use.

The PELICAN features full-color RGB cameras and shape recognition technology to effectively remove defective seeds and foreign material. Its design prioritizes ease of maintenance. Components are readily accessible, and the software is intuitive, simplifying routine cleaning and servicing. This focus on low-maintenance operation ensures the machine remains productive and reduces the long-term cost of ownership.

The table below provides a side-by-side comparison of the top models discussed.

| Model | Primary Strength | Accuracy | Est. Cost | Throughput | Footprint |

|---|---|---|---|---|---|

| Bühler SORTEX A | Unmatched Purity | Very High | High | High | Large |

| Taiho CCD Sorter | Budget-Friendly | Good | Low | Medium | Medium |

| Akyurek SORTURK C-5 | Compact Design | Good | Medium | Low-Medium | Compact |

| TOMRA Nimbus BSI+ | Scalability | Very High | High | High | Scalable |

| Satake PELICAN | Low Maintenance | Good | Medium | Medium | Medium |

Final Takeaway 🎯 The ideal sunflower seeds optical sorter aligns with a core business goal. Businesses should first define their top priority. This focus—whether on premium quality, budget efficiency, or space conservation—directly informs the best investment for their specific operational needs.

A business seeking premium quality should consider advanced cameras. Standard RGB cameras handle basic color sorting. Advanced systems like InGaAs or BSI+ detect invisible defects for maximum purity.

Payback periods vary based on usage. Key factors include labor cost savings, higher product value, and reduced material waste. Many businesses see a return in 18-36 months.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Both fat analysis and contaminant inspection (bone...

Glass-in-glass / Metal-in-metal inspection, small ...

Recommedation: Frozen vegetables such as green be...

Recommedation: Small particle, flat products such...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Advanced nut sorting machine technology combines H...

MoreRaymanTech, as a leading provider of inspection an...

MoreIn the high-volume world of meat processing,...

MoreCupped products, such as Greek yogurt and multi-co...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Control ManagerThis sunflower seeds optical sorter has revolutionized our production line. The accuracy in detecting defective seeds is remarkable, and the processing speed has increased by 40%. Maintenance is straightforward and the technical support team is very responsive.

Sarah Chen

Production SupervisorOutstanding performance! The optical sorter consistently delivers 99.8% accuracy in sorting sunflower seeds. The user interface is intuitive, and the machine's durability has significantly reduced our downtime. A fantastic investment for any seed processing facility.

David Thompson

Operations DirectorHighly efficient machine that has improved our seed quality substantially. The color recognition technology is precise, and the ejection system works flawlessly. The only minor issue was the initial setup, but the installation team was very helpful.

Jennifer Williams

Plant ManagerThis optical sorter has exceeded our expectations. The ability to handle high volumes while maintaining exceptional sorting quality has transformed our operation. The machine's reliability and low maintenance requirements make it an invaluable asset to our facility.