Technical Blog

-

Nov-18-2025

RaymanTech X-ray Inspection Systems: The Complete Guide to a Smarter, Safer Production Line

When a single shard of glass, a fragment of bone, or an unnoticed plastic tie can trigger a multimillion-dollar recall and shatter consumer trust, food manufacturers can no longer rely on yesterday’s detection technology. RaymanTech has built an entire ecosystem of X-ray inspection solutions that go far beyond traditional metal detectors, delivering density-based, shape-aware, AI-enhanced inspection across every product format imaginable.Learn More -

Nov-18-2025

Introduction to RaymanTech Optical Sorters for Farm Products and Food Processors

RaymanTech, as a leading provider of inspection and sorting solutions, has developed a comprehensive optical sorter portfolio that now serves both farm-product applications and food-processing environments. While farm-product sorters focus on capacity, adaptability, and raw-material variability, food-processor-grade sorters must also incorporate high IP protection, robust stainless-steel construction, sanitary design, and harsh washdown compatibility.Learn More -

Sep-12-2025

How Safe is X-ray Inspection of Food?

Consumers and manufacturers alike worry about contamination in food – broken glass, metal fragments, plastic or stone – entering a product and harming someone or prompting a recall. X-ray inspection systems have become a key solution: conveyors carrying packaged or unpackaged food pass through a shielded X-ray machine that “sees” inside each item. This technology complements traditional metal detectors and manual checks to catch a wider range of hazards. Importantly, extensive research and industry experience show that food X-ray inspection is extremely safe. Nearly everything we eat – from spices to snacks – is X-rayed at some point during production, and regulatory bodies (like the FDA) report “no known adverse effects” from the low-dose X-ray scans used in food plants.Learn More -

Jan-08-2026

The Ultimate Guide to Ready Meals X-Ray Inspection: Ensuring Safety and Quality in Every Tray

In this guide, we explore how advanced Ready Meals x-ray machine technology safeguards your products and why it is the gold standard for modern food processing.Learn More -

Dec-17-2025

Comprehensive Introduction to IP69K Protection Rating — The Gold Standard for Equipment in Meat and Food Processing Environments

Why do IP65/IP67 fail in food plants? Discover the engineering behind true IP69K hygienic design and our water-resistant X-ray inspection solutions.Learn More -

Nov-21-2025

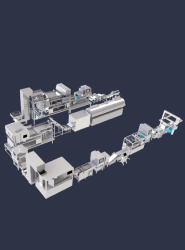

RaymanTech Whole-Chain Solution: A Deep Dive

Food safety and quality control demands have evolved dramatically. Modern food processors can no longer rely on spot-checks or isolated inspection points — contaminants, defects, and non-conformities can originate at any stage: raw ingredients, processing, or final packaging. RaymanTech’s Whole-Chain Inspection & Sorting SolutionLearn More -

Nov-19-2025

RaymanTech Bulk X-ray Inspection:The First and Most Important Line of Defense in Food Safety

In food processing, the highest-risk moment isn’t at the final packing station—it’s the second a truck backs up to the silo and unloads tons of raw nuts, grains, seeds, spices, dried fruit, coffee, or frozen vegetables. At that point, everything is mixed together: the good product you paid for, plus stones from the field, metal from harvesting equipment, glass from a broken bulb in the dryer, twigs, leaves, shells, insect-damaged kernels, moldy berries, and pieces of plastic baling twine.Learn More -

Nov-19-2025

RaymanTech Standard Dual Energy X-ray: Seeing the Invisible in Overlapped and Uneven Products

Picture a high-speed frozen broccoli line running at 60 meters per minute. Thousands of dark-green florets tumble straight from the IQF tunnel onto the belt. They overlap, fold, twist, and pile two or three deep. Some are still lightly coated with ice, others are perfectly dry. Hidden somewhere in that moving green avalanche is a sliver of blue plastic film, a tiny piece of rubber gasket, or a fragment of thinLearn More -

Nov-19-2025

RaymanTech Dual Energy Residual Bone Detector: Absolute Bone Removal in Poultry Processing

Bone fragments are the poultry industry’s most persistent and expensive headache. Even the most advanced mechanical deboning systems leave behind collar bones, rib tips, fan bones, cartilage shards, and calcified tendon ends. These remnants are rarely metallic, often flexible, and almost impossible to see with the naked eye once the fillet is marinated, breaded, or frozen. Yet consumers notice them immediately—and one viral complaint can cost millions in lost contracts and brand damage.Learn More -

Sep-12-2025

Principle of X-ray Inspection Machines in the Food Industry

X-ray inspection machines have become indispensable tools for food producers to catch hazards before products leave the plant. Unlike manual or camera-based checks, an X-ray system “sees” inside packaged or unpackaged items using penetrating radiation.Learn More

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

© 2015-2025 RaymanTech - Privacy Policy - Term of Use