Why X-Ray is Superior for Chocolate Inspection

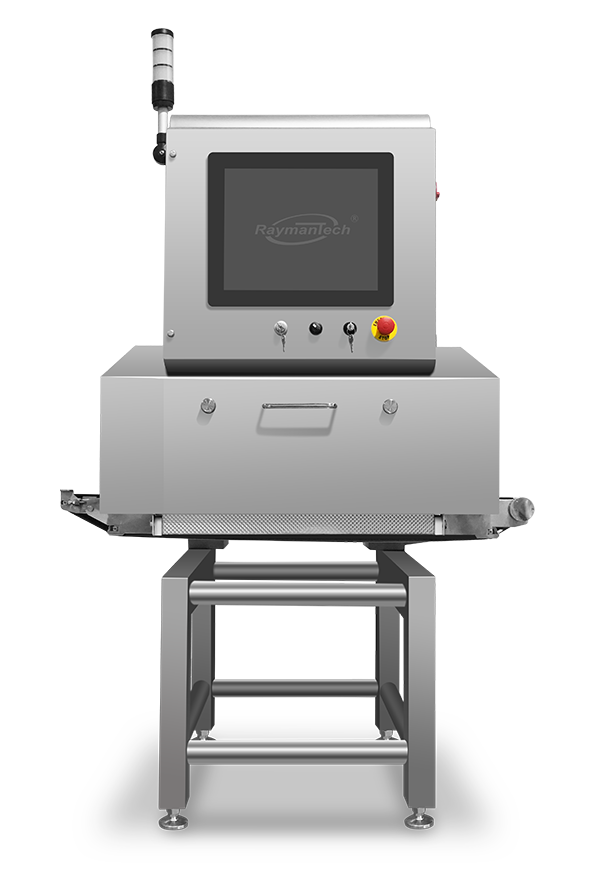

For manufacturers, ensuring that every bite is safe and perfect is not just a goal—it is a necessity. This is where x ray chocolate bars inspection technology becomes a critical asset. Here is a comprehensive guide to how X-ray inspection secures quality for both solid and filled chocolate products, powered by RaymanTech’s intelligent solutions.

Why X-Ray is Superior for Chocolate Inspection

Chocolate manufacturing involves complex processing steps—roasting, grinding, conching, and tempering—where machinery wear and tear can introduce foreign bodies. Furthermore, premium chocolate is often wrapped in aluminum foil or metallized film, which renders standard metal detectors ineffective due to the "product effect."

X ray chocolate bars inspection systems bypass these limitations. They penetrate packaging to visualize density differences, allowing them to detect non-metallic contaminants and perform internal quality checks without damaging the product.

Specific Applications by Chocolate Type

Different chocolate formats present unique challenges. Below is a breakdown of how X-ray technology addresses the specific needs of solid versus filled confectionery.

1. Milk Chocolate, Dark Chocolate, and White Chocolate Bars

Solid bars require uniformity. Any deviation in density often signals a contaminant or a physical defect.

Contaminants Detection: The system identifies high-density foreign materials that may enter the stream during processing. This includes:

Metal: Specifically identifying fragments from production line spare parts, repair welding slag, and debris from drilling.

Environmental Debris: Stones, ceramics, and glass.

Process Debris: Rigid plastics that may chip off conveyor guards or bins.

Packaging Integrity: Ensuring the final presentation meets consumer standards is vital. X-ray systems verify:

The correct amount of filling or total mass.

Missing pieces within a sealed box (e.g., checking if a multi-pack is complete).

Misalignments of the bar within the wrapper, ensuring the seal does not trap the product.

Defect Detection: Beyond safety, the system ensures physical perfection by spotting:

Damages, breaks, or cracks in the bar.

Under-formed shapes caused by improper molding or dosing.

2. Filled Chocolate Bars, Chocolate Truffles, and Bonbons

Complex products with soft centers, nuts, or liqueurs add a layer of difficulty. X-ray technology excels here by distinguishing between the density of the shell, the filling, and potential contaminants.

Contaminants Detection: Just like solid bars, the system filters out dangerous impurities:

Metal: Detecting shards from production line spare parts, repair welding slag, and drilling residue.

Hard Contaminants: Stone, rigid plastics, ceramics, and glass.

Packaging Integrity:

Verifies the correct amount of filling weight.

Detects missing pieces in boxed assortments (e.g., a missing truffle in a gift box).

Identifies misalignments that could compromise the package seal.

Defect Detection: This is where X-ray is indispensable for filled products. It detects:

a. Damages, breaks, cracks, or under-formed outer shells.

b. Filled Hollowness and Half-filled: It can "see" inside the chocolate to ensure the filling is distributed correctly, rejecting products where air pockets or insufficient filling ruin the consumer experience.

The RaymanTech Advantage: AI-Powered Precision

RaymanTech elevates x ray chocolate bars inspection by integrating AI-powered large models and multi-spectral technology. Standard X-ray machines might struggle to differentiate between a dense nut inclusion and a small stone. RaymanTech’s intelligent algorithms analyze material attributes beyond just density.

Enhanced Accuracy: The AI reduces false rejects by "learning" the natural variations of your product, distinguishing between acceptable ingredients (like almonds or crisps) and actual contaminants.

Whole Chain Solution: RaymanTech provides an "All-in-One" solution that covers the entire line—from raw material sorting (cacao beans) to the final packaged product inspection.

Hygienic & Robust Design: With options for IP69K protection, RaymanTech machines are designed for the strict hygiene requirements of the food industry, allowing for high-pressure washdowns without risking sensitive electronics.

Virtual Weighing: The system simultaneously acts as a checkweigher, calculating the mass of each bar to ensure compliance with labeling regulations.

Frequently Asked Questions (FAQs)

Q1: Can X-ray inspection work with aluminum foil packaging?

A: Yes. This is one of the primary advantages of X-ray over metal detectors. X-rays can see right through aluminum foil and metallized film to detect stainless steel, ferrous, and non-ferrous metals, as well as glass and stone, without any interference from the packaging material.

Q2: Will X-ray inspection affect the taste or safety of the chocolate?

A: No. The radiation levels used in food inspection are extremely low and used for a fraction of a second. It does not affect the flavor, texture, or safety of the chocolate. The food remains organic and safe for consumption.

Q3: Can the system handle products with nuts and inclusions?

A: Yes. RaymanTech’s AI-powered systems are specifically designed to handle "noisy" product images. They can differentiate between the density of a hazelnut or wafer and the density of a contaminant like a stone or shard of glass, ensuring that valid products are not rejected.

Q4: What happens if a filling is missing from a truffle?

A: The X-ray system utilizes density contrast to spot the void. If a truffle is supposed to have a dense ganache center but contains an air pocket (hollow) or is only half-filled, the image analysis software will flag it as a defect and reject it from the line automatically.

Q5: How small of a metal contaminant can be detected?

A: Sensitivity depends on the product size and density, but modern high-definition (UHD) detectors can identify extremely small contaminants—often down to 0.6mm–0.8mm for metals—ensuring that even tiny shavings from spare parts or drilling are removed.

Last Opinion

In the confectionery industry, quality is defined by what is inside the wrapper. Whether you are producing solid dark chocolate bars or delicate filled truffles, x ray chocolate bars inspection provides the ultimate safeguard for your brand.

By leveraging RaymanTech’s AI-integrated solutions, manufacturers can go beyond simple metal detection. You can ensure that your production line is free from welding slag and spare part debris, verify that every bonbon is perfectly filled, and guarantee that your packaging is flawless.

Ready to elevate your food safety standards?

Discover how RaymanTech’s Whole Chain Inspection Solution can future-proof your confectionery line today. Contact RaymanTech to request a demo or learn more about our specialized confectionery solutions.

Related Articles

-

Nov-25-2025

Nov-25-2025RaymanTech X-ray Inspection Systems: The Complete Guide to a Smarter, Safer Production Line

When a single shard of glass, a fragment of bone, or an unnoticed plastic tie can trigger a multimillion-dollar recall and shatter consumer trust, food manufacturers can no longer rely on yesterday’s detection technology. RaymanTech has built an entire ecosystem of X-ray inspection solutions that go far beyond traditional metal detectors, delivering density-based, shape-aware, AI-enhanced inspection across every product format imaginable.learn more -

Nov-25-2025

Nov-25-2025Introduction to RaymanTech Optical Sorters for Farm Products and Food Processors

RaymanTech, as a leading provider of inspection and sorting solutions, has developed a comprehensive optical sorter portfolio that now serves both farm-product applications and food-processing environments. While farm-product sorters focus on capacity, adaptability, and raw-material variability, food-processor-grade sorters must also incorporate high IP protection, robust stainless-steel construction, sanitary design, and harsh washdown compatibility.learn more -

Nov-25-2025

Nov-25-2025How Safe is X-ray Inspection of Food?

Consumers and manufacturers alike worry about contamination in food – broken glass, metal fragments, plastic or stone – entering a product and harming someone or prompting a recall. X-ray inspection systems have become a key solution: conveyors carrying packaged or unpackaged food pass through a shielded X-ray machine that “sees” inside each item. This technology complements traditional metal detectors and manual checks to catch a wider range of hazards. Importantly, extensive research and industry experience show that food X-ray inspection is extremely safe. Nearly everything we eat – from spices to snacks – is X-rayed at some point during production, and regulatory bodies (like the FDA) report “no known adverse effects” from the low-dose X-ray scans used in food plants.learn more

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057