How Safe is X-ray Inspection of Food?

Consumers and manufacturers alike worry about cont...

More

The food safety testing market will reach USD 28.99 billion by 2026, demanding technology that addresses persistent risks. Foreign objects caused 11.4% of recent recalls, a problem advanced x ray food inspection now targets with AI.

This synergy moves the industry from a reactive to a proactive stance, creating automated protocols to satisfy both regulatory and consumer demands.

The rapid evolution of food safety technology is not happening in a vacuum. It is a direct response to a convergence of intense pressures facing the food industry. By 2026, companies must adopt advanced systems to navigate an increasingly demanding operational landscape.

Governments worldwide are tightening food safety regulations. In the United States, the primary driver is the FDA's Food Safety Modernization Act (FSMA) Rule 204, with a compliance deadline of January 20, 2026. This rule targets high-risk foods like leafy greens, certain cheeses, and seafood.

The rule mandates that businesses enhance traceability by maintaining precise records for Critical Tracking Events (CTEs). Companies must provide an electronic, sortable spreadsheet to the FDA within 24 hours of a request.

Modern food supply chains are global, intricate, and fragile. Geopolitical shifts and climate-related shocks create unpredictable disruptions, increasing the risk of contamination. A lack of harmonized international standards further complicates compliance, creating vulnerabilities where food safety can be compromised during transit or sourcing from new suppliers.

Today’s consumers demand unprecedented transparency. They want to know the origin of their food, how it was produced, and what safety measures are in place. This trend is a powerful market force; for example, a significant 86% of millennial moms will pay more for products offering complete transparency. Building this trust requires verifiable data that only advanced inspection and traceability systems can provide.

Despite modern processes, physical contaminants remain a persistent threat. These hazards can enter the production line from various sources, demanding robust detection methods. Common culprits include:

Metal fragments from processing machinery

Glass shards from containers

Dense plastic pieces from packaging

Stones and other debris from raw materials

These threats not only pose a direct risk to consumer health but also trigger costly recalls and damage brand reputation.

By 2026, Artificial Intelligence will no longer be an optional add-on for X-ray systems; it will be the engine driving their effectiveness. AI transforms standard inspection equipment into intelligent, self-optimizing assets that enhance safety, reduce waste, and streamline compliance. This integration creates a powerful synergy, moving food producers toward a future of automated, predictive food safety.

Traditional maintenance schedules are reactive, leading to unexpected equipment failures and costly production downtime. AI-powered predictive maintenance (PdM) shifts this paradigm from a fixed schedule to a condition-based approach.

AI algorithms process real-time sensor data from critical X-ray components, such as generators and tubes. They identify subtle patterns and anomalies that predict failures before they happen. This proactive strategy has helped industries reduce maintenance costs by up to 40% through increased equipment availability and extended asset life.

These predictive models operate on different timelines to ensure comprehensive oversight:

Short-term models detect immediate operational anomalies, like abnormal air-conditioning behavior in an X-ray system, allowing for quick adjustments.

Mid-term models forecast issues developing over weeks or months, such as predicting generator failure up to three months in advance by monitoring electrical parameters.

Long-term models support strategic planning by optimizing spare parts inventory based on the predicted failure rates of key components.

This intelligence is already delivering results across food processing. For example, AI monitoring a critical product transfer pump can detect the vibration signature of an early-stage seal failure. This alert allows for proactive replacement, preventing a major product leak and avoiding significant cleanup costs.

Food production lines are rarely static. Products vary in size, density, and shape, and line speeds can change. Conventional X-ray systems struggle to adapt, requiring manual recalibration that slows production. AI introduces dynamic inspection protocols that adjust automatically.

AI algorithms analyze products in real-time, instantly fine-tuning inspection parameters for each item. This capability allows the system to compensate for differently shaped products or shifting production speeds without human intervention. Deep learning, a subset of AI, uses neural networks to analyze complex visual patterns, spotting subtle differences that are often invisible to the human eye. This continuous learning process allows the x ray food inspection system to adapt to new product lines and identify novel defect types over time.

One of the most significant operational drains in food production is the false rejection rate—when safe, high-quality products are incorrectly flagged as contaminated. This issue often arises when a system misinterprets normal product variations, such as overlapping items or slight differences in shape, as defects.

Machine learning models solve this problem by learning what constitutes a "normal" product. By training on vast datasets of compliant products, AI learns to distinguish between harmless cosmetic variations and actual contaminants.

For example, advanced models like One-Class Support Vector Machines (OCSVM) are trained exclusively on non-contaminated batches. They excel at identifying rare contamination events with near-perfect recall while maintaining high precision, drastically reducing the costly rejection of good products.

This intelligence allows an x ray food inspection system to correctly identify a misaligned cap or a missing stopper without flagging the entire batch, saving valuable resources and minimizing food waste.

Meeting regulatory requirements like FSMA Rule 204 involves immense administrative work. Manual record-keeping is time-consuming and prone to human error, creating significant compliance risks. AI automates this entire process, ensuring audit readiness at all times.

AI-powered platforms are emerging that integrate directly with inspection systems to generate compliance reports automatically.

Systems like IONI can generate a complete HACCP plan and supporting documents in auditor-ready PDF formats. The AI performs gap analysis, highlights missing procedures, and can even draft the required documentation.

Software such as FoodReady offers automated reporting for GFSI standards, linking inspection data directly to quality assurance and corrective action workflows.

This automation provides a centralized, digital record-keeping solution. It eliminates paper-based systems, tracks employee training certifications, and sends real-time alerts for potential non-compliance issues. By handling the administrative burden, AI frees up food safety managers to focus on proactive risk management rather than paperwork.

The evolution of x ray food inspection is accelerating beyond simple contaminant detection. By 2026, advanced X-ray systems will function as multifaceted quality assurance hubs. These technologies will leverage new hardware and sophisticated software to analyze products with a level of detail previously unimaginable, ensuring both safety and consistency.

Traditional X-ray systems primarily identify contaminants based on density differences. This method works well for finding metal in flour but struggles with complex products. Emerging systems overcome this limitation with superior material discrimination.

Dual-energy X-ray technology is at the forefront of this shift. It utilizes two different X-ray energy levels to analyze a product. This process allows the system to distinguish materials based on both their density and their atomic composition. The technology, often called Material Discrimination X-ray (MDX), measures the ratio of the two energy levels passing through an item. This measurement effectively differentiates organic materials (the food product) from inorganic materials (contaminants like glass or stone). This capability is especially valuable for inspecting foods that produce "busy" X-ray images with varied density, such as ready-to-eat meals or bags of mixed vegetables.

The ability to discriminate between materials directly translates to enhanced contaminant detection. Systems in 2026 will reliably identify foreign bodies that older technology would miss, particularly low-density contaminants that blend in with the food product itself. Advanced X-ray systems can now differentiate subtle density differences to find both high- and low-density threats.

These hard-to-find contaminants include:

Small or thin bones in poultry and fish fillets

Soft plastic fragments from packaging or equipment

Rubber pieces from gaskets or seals

Wood splinters and low-density stones

Innovations are coming from multiple directions. For example, some equipment manufacturers offer systems capable of detecting bone fragments down to 1mm. Other companies are developing "detectable materials," such as rubber gaskets blended with special additives, making them visible to X-ray and metal detectors if a fragment breaks off.

Beyond X-ray, other technologies like Hyperspectral Imaging and Surface-Enhanced Raman Spectroscopy (SERS) are emerging. These methods combine imaging with chemical analysis to detect issues like pesticide residue on fruit, even after washing. This shows a broader industry trend toward multi-layered, high-tech inspection.

Perhaps the most significant evolution is the expansion of X-ray capabilities from a safety tool to a comprehensive quality control instrument. By 2026, a single x ray food inspection system will perform numerous checks simultaneously, optimizing production and protecting brand integrity.

These systems offer a powerful layer of process control far beyond finding foreign objects. They can inspect products inside sealed packaging, a task impossible for many other inspection methods. Key quality control functions include:

Mass Measurement: Verifying that each package meets its target weight.

Component Count: Ensuring a multi-pack of yogurts or a box of chocolates contains the correct number of items.

Fill Level Monitoring: Checking that bottles are filled to the proper level without headspace violations.

Shape and Integrity Checks: Identifying broken, misshapen, or missing products, such as a cracked cookie in a sealed tray.

A critical quality function is verifying seal integrity. Advanced systems detect defects by measuring differences in X-ray absorption in the seal area. This allows them to spot product trapped in the seal or wrinkles that could compromise airtightness, preventing spoilage and ensuring product freshness for the consumer.

By 2026, standalone technologies will become obsolete. The future lies in an integrated ecosystem where AI, X-ray inspection, and supply chain data converge. This synergy creates a single source of truth, transforming food safety from a series of checkpoints into a continuous, intelligent process. This connected framework delivers unprecedented visibility and control.

An integrated system links a product's inspection data to its entire journey, from farm to fork. This capability is essential for meeting the stringent demands of FSMA Rule 204. When a recall occurs, companies can instantly trace a contaminated batch to its source. This process minimizes public health risks and limits financial damage.

A new generation of platforms enables this deep connectivity. They use technologies like blockchain, IoT, and cloud computing to create an unchangeable record for every item.

atma.io uses blockchain for item-level tracking.

Roambee deploys IoT sensor tags to monitor location and temperature.

Wholechain provides end-to-end traceability for product storytelling.

This ecosystem shifts safety management from reaction to prediction. AI algorithms analyze vast datasets from across the supply chain to identify potential hazards before they materialize. The system learns the unique risk profile of each product line and supplier.

Predictive analytics in AI systems analyze environmental data like temperature and humidity to forecast contamination risks. This allows teams to resolve problems proactively. AI-equipped sensors can also detect harmful chemicals, such as pesticide residues, in raw materials. This integrated intelligence provides rapid and accurate information, empowering managers to mitigate threats before they enter the production line.

The data generated by this ecosystem does more than ensure safety; it fuels growth. R&D teams gain deep insights into product consistency, ingredient performance, and packaging integrity. This information de-risks the innovation process. Companies can confidently test new formulations or sustainable packaging, knowing the system will verify quality and safety in real time. Brands like Knorr and Melitta Coffee already use traceability data to share ingredient origin stories with consumers, turning safety transparency into a powerful marketing tool.

Investing in an integrated AI and X-ray ecosystem is no longer a future consideration; it is a present-day strategic imperative. Companies that adopt these technologies early will secure a significant and lasting advantage. The business case extends far beyond compliance, creating value through market leadership, consumer loyalty, and operational excellence.

Early adopters position themselves as industry leaders. This advanced technological posture attracts premium clients and partners who prioritize supply chain resilience. Companies demonstrate a commitment to quality that differentiates their brand in a crowded marketplace. This reputation for innovation and safety becomes a powerful asset, enabling them to command higher prices and capture greater market share. Forward-thinking businesses use this edge to set new industry standards, forcing competitors to play catch-up.

Modern consumers demand transparency. An integrated inspection system provides the verifiable proof needed to build lasting trust. Companies can proactively demonstrate their commitment to safety, which is crucial for maintaining loyalty, especially after a potential recall event. Key practices include:

Proactive Communication: Regularly sharing information about safety protocols and system improvements.

Traceability and Source Information: Offering clear data on a product's journey from origin to shelf.

Real Accountability: Using system data to transparently address issues and demonstrate corrective actions.

Fostering a Safety Culture: Proving that safety is a shared, company-wide responsibility backed by technology.

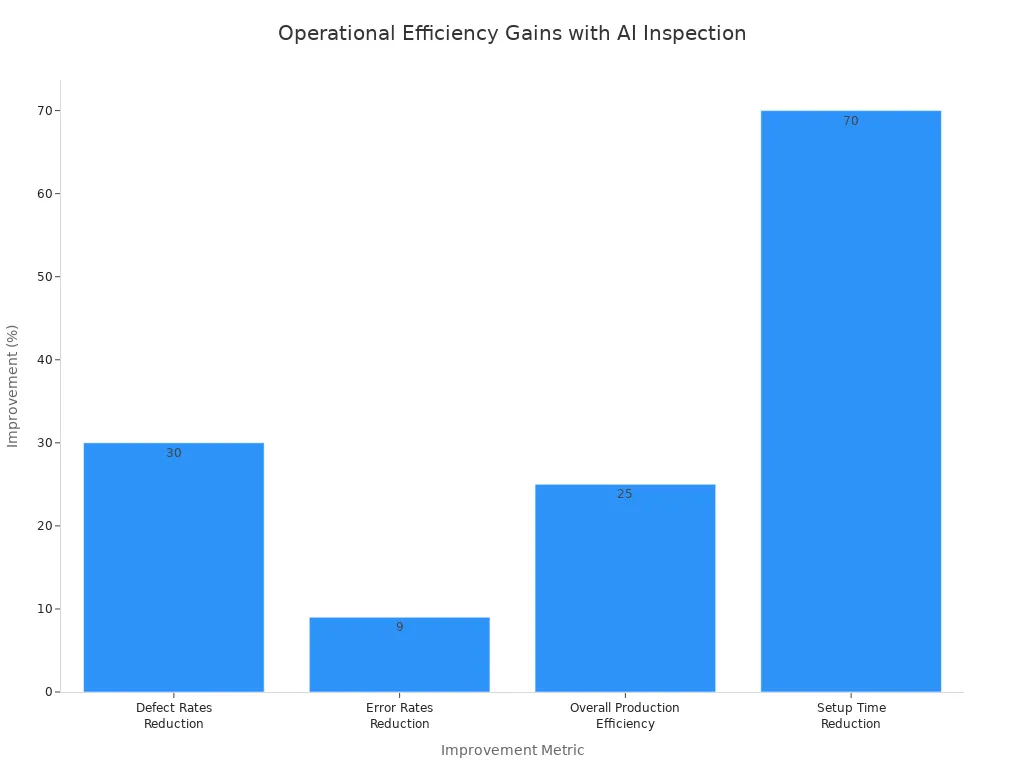

AI-powered inspection drives quantifiable gains in productivity. It automates complex tasks, reduces human error, and minimizes costly production halts. The system's ability to self-optimize and reduce false rejections directly translates to higher throughput and less food waste. These improvements create a leaner, more profitable operation.

As seen across industries, AI integration delivers dramatic results. Error rates can fall below 1% compared to 10% for manual inspectors. Furthermore, adaptable AI systems reduce setup time for new inspections by up to 70%, boosting overall production efficiency.

By 2026, the synergy between AI and x ray food inspection will be a non-negotiable standard for food safety leadership. Adopting these integrated technologies is the key to meeting complex regulatory demands, including the FDA's FSMA 204 rule. Companies that invest now secure a decisive advantage through superior safety and efficiency.

AI transforms X-ray systems into intelligent assets. It boosts detection accuracy, reduces false rejections, and automates compliance, creating a proactive safety model for food producers.

The integrated system automates data collection for Critical Tracking Events. It generates the electronic records required by the FDA, ensuring companies meet the 2026 compliance deadline.

No, scalable solutions are emerging. Cloud-based platforms and modular systems make advanced inspection accessible for small and mid-sized businesses without requiring massive upfront capital investment.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

UHD X-Ray detector, AI large model, all food indus...

High cost performance, compact design, high sensit...

Recommedation: Aquatic products, pet food, candy, ...

Glass-in-glass / Metal-in-metal inspection, small ...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Consumers and manufacturers alike worry about cont...

MoreX-ray inspection machines have become indispensabl...

MoreThis article delves into the persistent pain point...

MoreWhen a single shard of glass, a fragment of bone, ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Control ManagerThis x-ray food inspection system has revolutionized our quality control process. The detection accuracy for contaminants is exceptional, and the false rejection rate has dropped significantly. Highly recommended for any food processing facility.

Sarah Chen

Production SupervisorImpressive x-ray inspection machine that reliably detects foreign objects in our packaged products. The user interface is intuitive and the maintenance requirements are minimal. Has greatly improved our product safety standards.

David Thompson

Plant ManagerOutstanding performance in detecting bones in our meat products. The system's sensitivity settings are precise and the throughput matches our production line speed perfectly. A valuable investment for food safety compliance.

Jennifer Williams

Quality Assurance SpecialistReliable x-ray inspection equipment that consistently identifies contaminants in our baked goods. The image clarity is excellent and the automatic rejection system works flawlessly. Has significantly reduced our recall risks.