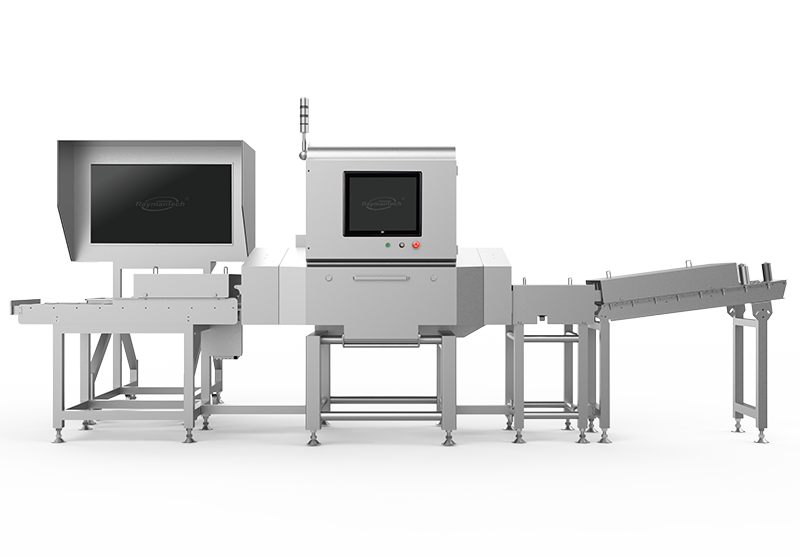

X-Ray Inspection System for Fish Bone

Automatic recognition and rejection, fish bone inspection (salmon, cod, basa fish, mackerel)

Model: RXD-MS-2410F, RXD-MS-4010F

brief introduction

-

Features

· Fish bone inspection

· AI powered UHD detector

· Tiny contaminant inspection /p>

· Auto recognition, auto rejection

· Unique design, IP69K available

· Data transfer and remote support

-

Application

Widely used to check fish bones in fish meat like salmon, cod, basa fish, mackerel, etc.

Advantages

-

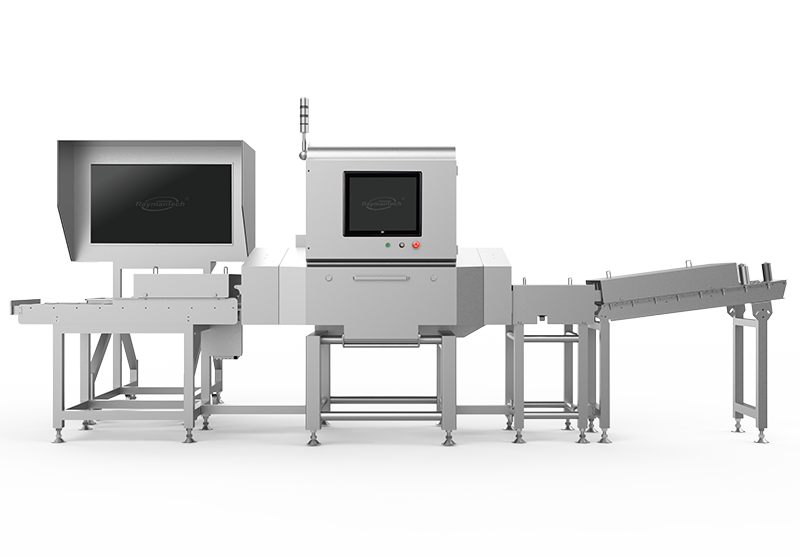

Fish Bone Detection

Detects bones in salmon, cod, basa, mackerel, etc. -

AI-Powered Imaging

Uses UHD detector with AI algorithms for precise inspection. -

Tiny Contaminant Detection

Identifies small foreign objects such as metal and plastic. -

Automatic Rejection

Automatically detects and removes defective products. -

Hygienic IP69K Design

Unique structure supports full washdown for food safety. -

Remote Support

Remote diagnostics for efficient control.

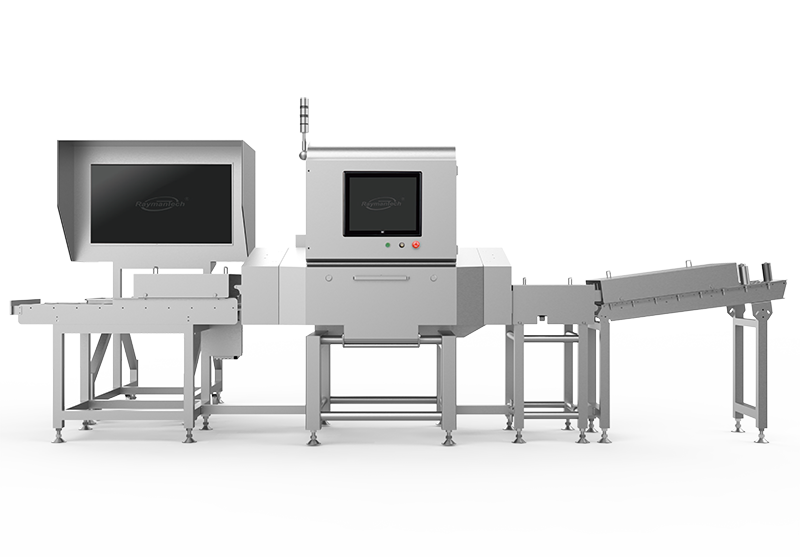

parameter

| Inspection Width | 200-400mm |

| Inspection Height | 100mm |

| Conveyor Speed | 10-40m/min |

| X-ray Leakage | < 1uSv/h |

| IP Rate | IP67/69K |

| Cooling Method | Air Conditioned Cooling |

| Working Temperature | 0-40°C |

| Working Humidity | 30-90% |

| Power Supply | 220V, AC, 50/60Hz |

Feel free to ask us anything, we will respond in 24 hours.

Industry

FAQ

-

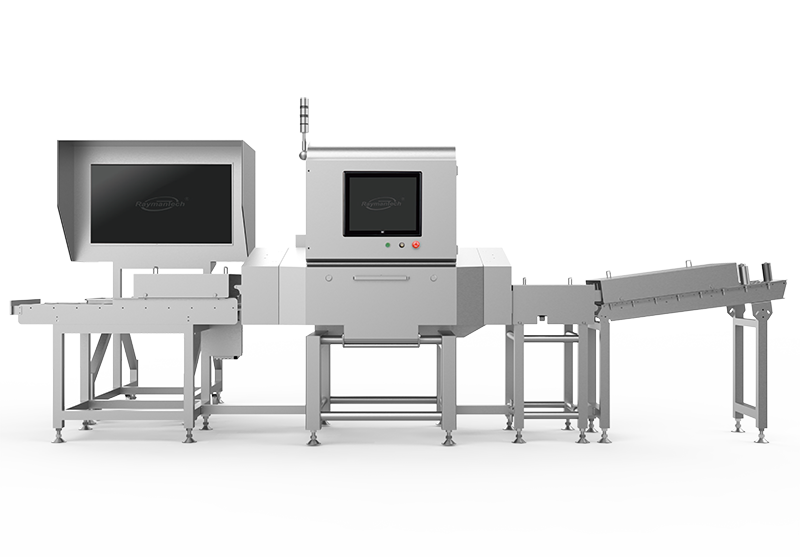

What contaminants can Raymantech X-Ray systems detect?

Raymantech’s X-Ray inspection systems detect metal, glass, ceramic, stone, hard plastic, bone, dense rubber, and other dense impurities. They inspect based on material density rather than conductivity, detecting non-metallic items that metal detectors miss.

-

Can the X-Ray machine inspect for things beyond contaminants (e.g., integrity, composition)?

Yes. Beyond foreign contaminant detection, Raymantech’s systems also perform product-integrity checks—such as sealing, missing components, fill-level, weight estimation—and fat-content analysis for monitoring composition in meat processing.

-

What makes Raymantech’s X-Ray equipment unique?

Raymantech’s whole-chain inspection capability from raw to packaged products, and AI-powered image processing for high accuracy and connectivity.

-

Which industries are served by Raymantech X-Ray systems?

Industries include meat, seafood, poultry, dairy, nuts, bakery, snacks, coffee, grains, canned/bottled food, pet food, frozen vegetables/fruits, convenience food, baby food and etc. Also suitable for pharmaceutical applications.

-

How does fat-content analysis work in these systems?

The fat-content analyzer uses X-Ray imaging with calibrated algorithms to estimate fat percentage or lean ratio, helping with nutritional labeling, cost control, and process inspection.

-

Are the systems safe and hygienic for food environments?

Yes. They meet CE radiation standards (<1 μSv/h) and feature stainless-steel, hygienic designs with IP65/67/69K options for wash-down and cold environments.

-

How do I select the right model for my line?

Key factors include product type, packaging, throughput, contaminant risks, and optional features like weight or fat-content analysis. Raymantech offers sample testing to validate performance before purchase.

-

Does the system support AI-based inspection?

Raymantech provides remote service, data logging, spare parts, and validation services. Regular cleaning, calibration, and software updates ensure consistent accuracy and reliability.

-

Can X-Ray machines inspect large or irregularly shaped packages?

Yes. Raymantech offers systems with various tunnel sizes and large-window designs to accommodate bulk or large-pack products.

-

What about maintenance and support?

The system features hygienic stainless-steel design, quick disassembly, and auto-diagnostic functions to simplify cleaning and maintenance.

Quick Links

Contact

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

.png)