Meat Packaging Revolution: Mastering Detection Challenges with Next-Gen X-ray and Vision Systems

This article delves into the persistent pain point...

More

Mettler-Toledo, Eagle Product Inspection, Anritsu, Mekitec, and Ishida lead the market for food safety technology. These manufacturers provide critical systems that detect physical contaminants, ensuring product integrity and protecting brand reputation. The x ray inspection equipment in food industry finds foreign materials such as:

Metal

Glass

Stone

Plastic

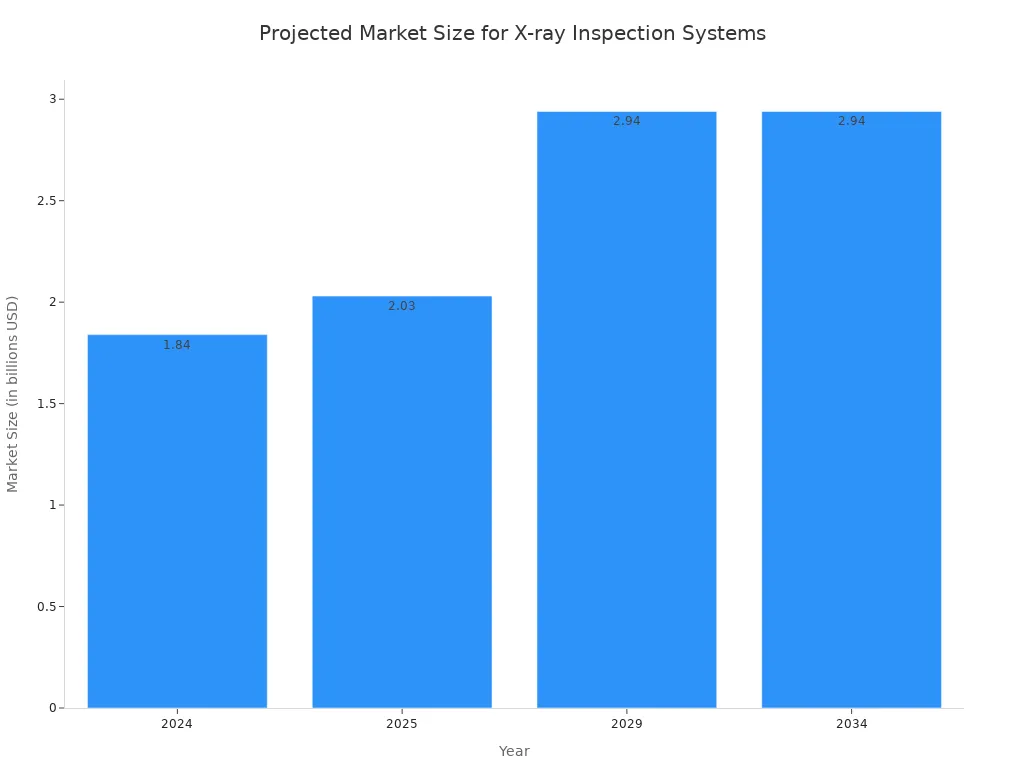

The market for these systems shows significant growth, reflecting their increasing importance.

Mettler-Toledo stands as a global leader in product inspection, offering a comprehensive portfolio of X-ray systems. The company builds robust equipment for a wide range of food and beverage manufacturers, establishing a strong reputation for reliability and precision.

Mettler-Toledo systems excel in diverse and demanding production environments. They are particularly well-suited for manufacturers in specific sectors, including:

Pumped food products like slurries, semi-solids, and fluids

Meat and poultry processing

Frozen dessert and beverage packaging lines

The company equips its systems with advanced technology to maximize safety and operational efficiency. Their X-ray machines feature HiGain+ detector technology, which provides exceptional detection of contaminants like metal, glass, and calcified bone. The ContamPlus™ software platform enhances detection algorithms while simplifying operation for users.

Many systems also come with a five-year generator warranty when paired with a service contract. This feature offers long-term peace of mind and protects a critical component of the equipment.

Processors choose Mettler-Toledo for its proven performance and adaptability. Major brands like J&J Snack Foods rely on their systems for quality assurance. The equipment effectively inspects products even when packaged in challenging materials, such as metalized film. Additionally, hygienic design features like tool-free belt removal simplify cleaning and maintenance, reducing downtime and supporting food safety protocols.

The primary drawback of Mettler-Toledo systems is their cost. The initial investment can be significant, potentially placing them outside the budget for smaller manufacturers. Furthermore, some users report that system performance can decrease if the production line frequently switches between different products that require unique inspection settings and calibrations.

Eagle Product Inspection carves out a significant market share with its focus on advanced technology and application-specific solutions. The company is renowned for developing systems that tackle historically difficult inspection challenges, particularly those involving dense or complex products.

Eagle's equipment is engineered for processors with demanding applications. It provides superior performance in several key sectors:

Poultry Processing: Reliably detects calcified bones and other foreign bodies in chicken and other poultry products.

Seafood & Dairy: Inspects everything from frozen fish filets to yogurt cups, checking for contaminants and verifying fill levels.

Fruits & Vegetables: Locates unwanted materials in products with high textural variation, like dried fruits.

Rigid Containers: The Tall PRO XSDV system is ideal for inspecting upright products like cans, glass jars, and PET bottles.

Innovation is central to Eagle's product design. Their systems incorporate proprietary technologies to enhance detection. Material Discrimination X-ray (MDX) technology differentiates materials by their chemical composition, allowing it to find inorganic contaminants like glass and rock in "busy" product images. The advanced SimulTask™ PRO software processes high-resolution images and performs multiple quality checks simultaneously.

For even greater precision, Eagle’s exclusive Photon-counting Dual Energy (PXT™) detector captures more detailed product data. This results in higher detection accuracy and significantly reduced false reject rates.

Processors gain a powerful tool for regulatory compliance. Eagle systems help manufacturers meet HACCP-based Global Food Safety Initiative (GFSI) standards, including BRCGS and SQF. The equipment provides excellent traceability, helping to pinpoint where contaminants may have entered the production line. This robust documentation and automatic rejection of non-conforming products helps brands avoid costly recalls and build consumer trust.

The advanced capabilities of Eagle's systems often come with a higher initial cost, which can be a barrier for smaller operations. The sophistication of technologies like MDX may also require more specialized operator training to maximize performance and leverage the full range of features.

Anritsu earns its place with a strong focus on high-performance detection and operational durability. The company designs robust systems that deliver precision and reliability, making its x ray inspection equipment in food industry a top choice for processors facing challenging production conditions.

Anritsu systems are engineered to perform in demanding plant environments. They are an excellent fit for facilities with specific operational challenges, including:

Wet or oily production lines where water is frequently used.

Dusty environments, such as those handling powders or spices.

Lines processing tall, upright products like cartons, aseptic boxes, and PET bottles.

Anritsu integrates its proprietary Ultra HD imaging technology to achieve superior detection. This technology combines high-sensitivity sensors and beryllium window tubes to find very small contaminants. Unique image processing algorithms filter out product "noise," enhancing the system's ability to spot foreign bodies like bone, glass, and metal.

Anritsu's UltraHD technology can detect contaminants as small as 0.2 mm diameter ferrous, non-ferrous, and stainless steel spheres at full production speeds.

Processors benefit from Anritsu's emphasis on user-friendliness and simple maintenance. An auto-learn product setup wizard guides operators through configuration, reducing setup time. The equipment's design also simplifies upkeep. Angled surfaces prevent water from pooling after cleaning, and operators need no tools to remove conveyor belts or protective curtains, which minimizes downtime.

The primary challenge when considering Anritsu is its non-transparent pricing. The company does not publish costs, requiring businesses to request a direct quote. While Anritsu claims its technology can reduce lifetime ownership costs by up to 20% through component longevity and lower power use, the initial investment remains an unknown that can complicate budgeting for some buyers.

Mekitec specializes in making X-ray inspection technology accessible to a wider range of food producers. The company focuses on developing compact, user-friendly, and cost-effective systems, carving out a niche with small to medium-sized manufacturers who prioritize value and efficiency.

Mekitec systems provide an excellent entry point into X-ray inspection. They are particularly effective for producers with limited factory space or budget constraints, including:

Bakeries and confectioneries

Dairies and ready-meal producers

Small-scale food companies transitioning to automated inspection

The company engineers its systems for simplicity and a low total cost of ownership. Mekitec’s MEKI and MIDMEKI product lines feature a very small footprint, allowing for easy integration into existing production lines. The systems use intuitive, icon-based software that simplifies operator training and daily use.

Mekitec designs its equipment for low power consumption. This feature helps reduce operational costs over the system's lifetime, adding to its overall value proposition.

The primary advantage of Mekitec is its affordability. The company delivers reliable quality control without the high initial investment required by some competitors. Its compact design solves space challenges for many facilities. Furthermore, the straightforward software and easy maintenance routines minimize downtime and reduce the need for highly specialized technical staff, making advanced food safety achievable for more businesses.

Mekitec's focus on value and compactness comes with some trade-offs. Its systems may not offer the same level of performance for very high-speed production lines compared to more premium models. Processors with extremely complex products or those needing to detect the absolute smallest contaminants in challenging applications might find the capabilities of other manufacturers more suitable.

Ishida is a powerhouse in the food packaging industry, known for its weighing and packing solutions. The company extends this expertise to its X-ray inspection systems, offering robust quality control that integrates seamlessly into a complete production line.

Ishida systems are an excellent choice for food producers who want to source a fully integrated packaging line from a single supplier. They are particularly beneficial for:

Processors using other Ishida equipment like multihead weighers or tray sealers.

Manufacturers who need to perform multiple quality checks, including contaminant detection, weight estimation, and seal integrity.

Companies with global operations requiring consistent support across different regions.

The standout feature of Ishida's equipment is its patented Genetic Algorithm (GA) technology. This advanced image processing software uses a self-learning approach to optimize detection for specific products and foreign bodies.

The GA analyzes image data over multiple generations. This process fine-tunes the machine's sensitivity, enabling it to find difficult-to-detect contaminants with high accuracy, even at full production speeds.

The primary advantage is the enhanced efficiency gained from a fully integrated Ishida line. Combining an X-ray system with their weighers and sealers improves accuracy and allows for simultaneous checks for defects, missing items, and product weight. Additionally, Ishida and its partners, like Heat and Control, provide a comprehensive global support network. This ensures access to spare parts, training, and technical assistance regardless of a plant's location.

While powerful, the Genetic Algorithm may require a more involved initial setup to "train" the system for optimal performance on specific products. For businesses only seeking a standalone X-ray unit, the benefits of Ishida's integrated ecosystem may be less compelling compared to brands that focus exclusively on inspection technology.

Choosing the right manufacturer requires a clear understanding of each company's core strengths and ideal applications. The table below offers a high-level summary, helping you quickly compare the top five providers of x ray inspection equipment in food industry. This side-by-side view highlights key differences in technology, target markets, and overall value.

| Feature | Mettler-Toledo | Eagle Product Inspection | Anritsu | Mekitec | Ishida |

|---|---|---|---|---|---|

| Best For | Diverse, demanding environments; pumped foods and meat processing. | Complex applications; poultry, seafood, and products in rigid containers. | Wet, oily, or dusty environments; tall, upright products. | Small to medium-sized producers with space or budget limits. | Fully integrated packaging lines from a single supplier. |

| Key Technology | HiGain+ detector; ContamPlus™ software. | MDX and PXT™ for material discrimination. | UltraHD imaging for detecting very small contaminants. | Compact, low-power consumption systems. | Genetic Algorithm (GA) for self-learning detection. |

| Primary Strength | Proven reliability and adaptability across many sectors. | Superior detection of difficult contaminants like bone and glass. | High performance in harsh plant conditions; user-friendly. | Affordability and a small footprint for easy integration. | Seamless integration with other Ishida packaging equipment. |

| Potential Drawback | High initial investment cost. | Higher cost and need for specialized operator training. | Non-transparent pricing requires a direct quote. | May lack performance for very high-speed or complex lines. | Setup can be more involved; best value is in an integrated line. |

Pro Tip: Use this table to create a shortlist of manufacturers. Then, contact each one to discuss how their systems can address your specific product, environment, and compliance needs.

Selecting the right system requires a careful evaluation of your unique operational needs. A manufacturer's technology must align with your specific risks, environment, and production goals to deliver maximum value and protection.

A company must first identify its most likely contaminants. Different raw materials and processes introduce unique hazards. For example, bakery and dairy producers face distinct microbiological and physical risks.

Flour, a raw agricultural product, can carry Salmonella into a facility. Egg-based fillings added after baking can also introduce bacteria if handled improperly.

The dairy industry manages pathogens like Listeria and E. coli from raw milk. It also guards against physical hazards like metal fragments from machinery wear.

Understanding these risks helps a business choose a system optimized for detecting those specific foreign bodies.

The physical conditions of a plant heavily influence equipment choice. A system must withstand the daily operational environment. Facilities with frequent high-pressure washdowns need machines with high IP ratings and hygienic designs. Dusty environments, such as those in bakeries or spice plants, require sealed enclosures to protect sensitive electronics. The right x ray inspection equipment in food industry is built to perform reliably in your specific setting.

Production speed is a critical factor. A system must keep pace with the line without sacrificing accuracy. Modern X-ray systems maintain excellent detection performance even at very high speeds.

Some advanced systems can inspect products at speeds exceeding 600 packs per minute, ensuring that high-volume lines do not experience bottlenecks.

Unlike some other inspection methods, X-ray accuracy remains consistent regardless of the product repetition rate.

An investment in x ray inspection equipment in food industry must be balanced with regulatory requirements. These systems are essential tools for complying with global food safety standards, including HACCP plans and GFSI-benchmarked schemes like BRC and IFS. The equipment provides digital logs and verifiable data, offering the traceability needed to satisfy auditors. This documentation proves that a company is taking preventive measures to ensure product integrity.

Choosing a manufacturer like Mettler-Toledo or Eagle depends on a company's specific risks and budget. Investing in quality x ray inspection equipment in food industry is a critical step. It protects brand reputation and consumer safety, as physical contaminants are a leading cause of recalls.

Contact our experts to discuss your specific food inspection needs and find the perfect solution for your production line.

Metal detectors find only metallic contaminants. X-ray systems detect a wider range of foreign bodies, including glass, stone, and bone, while also performing additional quality checks.

Yes, the process is completely safe. Food inspection systems use very low radiation levels. They do not harm the food's nutritional value, texture, or taste.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Recommedation: Small particle, flat products such...

UHD X-Ray detector, AI large model, all food indus...

Recommedation: Chili, walnut, peanuts, soybeans, c...

Automatic recognition and rejection, fish bone ins...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

This article delves into the persistent pain point...

MoreCupped products, such as Greek yogurt and multi-co...

MoreWhy do IP65/IP67 fail in food plants? Discover the...

MoreX-ray inspection machines have become indispensabl...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Assurance ManagerThis X-ray inspection system has revolutionized our foreign object detection process. The sensitivity is exceptional, consistently identifying sub-millimeter contaminants in our packaged nuts. The false rejection rate is remarkably low, which has significantly improved our production efficiency.

Sarah Chen

Production SupervisorAfter implementing this X-ray equipment in our frozen vegetable line, we've achieved near-perfect detection of stones, glass fragments, and metal shards. The intuitive interface requires minimal training, and the maintenance support has been outstanding. A game-changer for food safety compliance.

David Thompson

Plant ManagerThe automated rejection system integrated with this X-ray machine has dramatically reduced our manual inspection costs. While the initial investment was substantial, the ROI through reduced recalls and improved customer trust has been impressive. Minor software glitches were quickly resolved by their support team.

Jennifer Park

Food Safety DirectorThis inspection equipment consistently detects bone fragments in our poultry products with incredible accuracy. The hygienic design meets all food safety standards, and the comprehensive reporting features have simplified our compliance documentation. Essential equipment for any serious meat processor.