Comprehensive Introduction to IP69K Protection Rating — The Gold Standard for Equipment in Meat and Food Processing Environments

Why do IP65/IP67 fail in food plants? Discover the...

More

Physical contaminants pose a significant threat to food safety. Recent recalls highlight this danger, with incidents involving materials found in everyday products.

Glass: sauce, orange juice

Metal: pastry, cheese

Plastic: fruit bars, sausage

The x ray inspection food industry uses systems that offer comprehensive quality control. These tools verify product integrity, checking fill levels and identifying damaged packaging. This investment protects brand reputation, with the market's projected 7.39% CAGR reflecting growing trust in the technology.

Top food brands implement x-ray inspection to gain a decisive advantage in safety and quality. This technology provides a level of scrutiny that older methods cannot match, transforming a production line into a comprehensive quality assurance checkpoint.

Traditional metal detectors are a valuable part of any safety program. They cannot, however, identify a wide range of common physical hazards. X-ray inspection systems excel where metal detectors fall short. They reliably find dense foreign bodies that are invisible to other technologies.

These systems detect contaminants based on their density. Food products typically have a low density. Contaminants are usually much denser, absorbing more x-rays and creating a clear contrast on an inspection image. This principle allows x-ray systems to locate:

Glass shards

Mineral stone and ceramic fragments

Calcified bone pieces

High-density plastics and rubber compounds

Contaminants inside metallic packaging like foil pouches or cans

A sausage manufacturer, for example, faced a potential recall after discovering bone fragments in its product. The company used an x-ray inspection service to locate the fragments, trace the contamination to a specific supplier, and prevent compromised products from reaching consumers.

The detection of plastics presents a unique challenge. Advanced systems overcome this with specialized technology. Dual-energy x-ray systems, for instance, use two different energy spectrums to identify materials based on their chemical composition, not just density. This greatly improves the detection of low-density contaminants like flat glass and certain plastics. The modern x ray inspection food industry leverages systems with powerful generators and sophisticated software to maximize detection capabilities.

A key reason the x ray inspection food industry is growing is the technology's multifunctionality. These systems do more than just find contaminants. They act as all-in-one quality control stations, performing numerous checks simultaneously on 100% of products without slowing production.

X-ray systems use advanced imaging software to analyze every item passing through the line. This allows brands to:

Verify Fill Levels: The system checks that every container, from a jar of sauce to a bag of chips, is filled to the correct level. It can even send real-time feedback to filling machines to make immediate adjustments, reducing product waste and ensuring consistency.

Measure Mass: Instead of using a separate checkweigher, x-ray systems can measure the overall mass of a product in-line. This function is critical for verifying label weight claims and ensuring portion control at high speeds.

Confirm Component Counts: Brands can verify that all components are present inside sealed packaging. The system can count the number of cookies in a tray, ensure a promotional insert is included, or even confirm the presence of an internal oxygen absorber packet needed for freshness.

Inspect Seal Integrity: A compromised seal can lead to spoilage and safety risks. X-ray inspection identifies packaging defects like product caught in the seal area, wrinkles, or improper seals that could lead to leaks.

Check for Product Damage: The system can detect broken or misshapen products inside the final package, ensuring that only perfectly formed items reach the consumer.

This comprehensive analysis provides an unparalleled guarantee of product quality. It ensures every single item leaving the facility meets the brand's highest standards for both safety and integrity.

Beyond immediate safety checks, x-ray inspection provides a powerful strategic advantage. Food manufacturers use this technology to strengthen their operations, protect their financial health, and build a resilient brand that thrives in a competitive market. It is a proactive investment in long-term business stability.

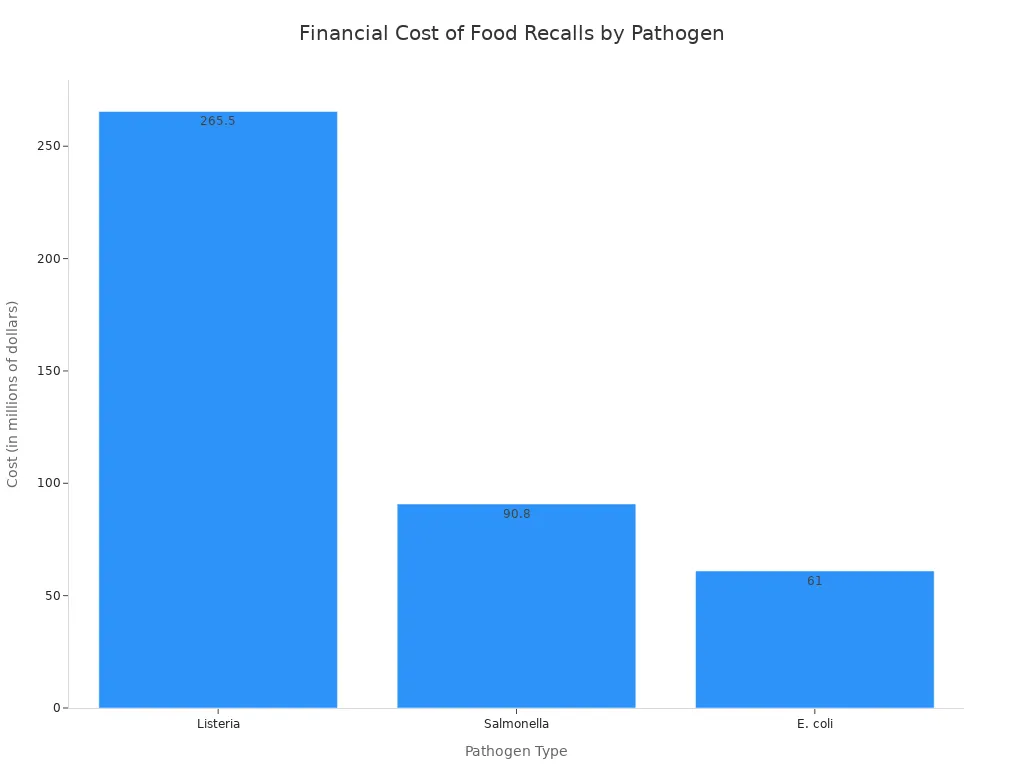

A food recall is one of the most damaging events a brand can face. The financial consequences are immediate and severe. A single major recall can reduce shareholder wealth by an average of 1.15%, which translates to a staggering $109 million for the average firm. The costs vary depending on the contaminant, with some recalls causing far greater financial harm.

X-ray inspection systems offer a direct defense against these catastrophic events. Physical contaminants are the second leading cause of recalls in the United States. A Canadian condiment manufacturer, for instance, successfully used an x-ray solution to prevent recalls from glass-in-glass contamination. The technology is specifically designed to find the "Faulty Five" common contaminants:

Glass

Metal

Mineral stone

Calcified bone

High-density plastics and rubber

By detecting and removing these hazards before products leave the facility, companies effectively eliminate the root cause of many recalls. The damage, however, extends far beyond the balance sheet. A recall shatters consumer trust. Studies show that 56% of consumers would not purchase a product that has been previously recalled. In one case, over 66% of consumers said they would avoid other products from a brand after a recall. This loss of loyalty can cripple a brand for years.

Protecting a brand means building confidence with two critical audiences: consumers and retailers. The visible use of advanced safety technology like x-ray inspection directly influences purchasing decisions. When consumers know a brand invests in top-tier safety measures, it fosters trust and a positive brand perception. This transparency demonstrates a clear commitment to delivering safe, high-quality products, which strengthens consumer relations and builds lasting loyalty.

Retailers also demand this level of commitment. Gaining and maintaining shelf space at major chains like Walmart requires adherence to strict food safety protocols. These retailers mandate that their suppliers meet high standards.

Retailer Requirements: A Look at Walmart

Suppliers for major retailers must often provide proof of their safety programs. Walmart, for example, requires its food suppliers to:

Obtain certification to a Global Food Safety Initiative (GFSI) recognized standard.

Make facilities and records available for audits and inspections at any time.

Participate in risk-based site reviews and implement Corrective & Preventive Actions (CAPA).

Comply with enhanced traceability requirements to meet regulations like FSMA 204.

Failure to meet these standards can lead to the termination of a business relationship. The modern x ray inspection food industry provides the verifiable proof of control that these retailers require, making it an essential tool for securing and growing key accounts.

Navigating the complex landscape of food safety regulations is a major challenge for manufacturers. The x ray inspection food industry helps companies meet these requirements efficiently. X-ray systems support adherence to all major GFSI-recognized standards, including BRC, SQF, and FSSC 22000. While these standards may not always explicitly name x-ray technology, they require robust foreign material control programs, for which x-ray is a best-in-class solution.

These systems are a cornerstone of modern food safety plans, including HACCP and the Food Safety Modernization Act (FSMA).

| Standard | How X-Ray Inspection Helps |

|---|---|

| HACCP | An x-ray system serves as a validated Critical Control Point (CCP), automatically detecting and rejecting physical hazards in real-time. |

| FSMA | It provides a key Preventive Control for physical hazards, generating the digital logs needed for verification, documentation, and traceability. |

Under FSMA, facilities must implement a written food safety plan based on hazard analysis. X-ray inspection directly addresses this by providing a reliable method for controlling physical hazards. The systems generate automatic, time-stamped reports for every product, creating a perfect digital audit trail. This simplifies record-keeping and makes it easy to demonstrate compliance during an audit. By integrating a powerful and verifiable control point, brands can confidently meet global standards and focus on producing great products.

Top food brands trust x-ray inspection for its comprehensive contaminant detection, which other systems cannot match. This technology is a powerful tool for proactive brand protection, minimizing recall risks and strengthening consumer relationships. Investing in x-ray inspection is a critical step toward guaranteeing product safety and securing long-term success.

Yes. X-ray inspection uses extremely low energy levels. The FDA confirms it does not harm food or make it radioactive, ensuring complete product safety for consumers.

X-ray systems detect a wider range of contaminants. They find glass, stone, and dense plastics, which metal detectors cannot identify, offering more comprehensive protection.

Yes. These systems perform multiple quality checks. They verify fill levels, measure product mass, and inspect package seals, all on the same production line.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Conventional and unconventional contaminant detect...

Glass-in-glass / Metal-in-metal inspection, small ...

High cost performance, compact design, high sensit...

Chicken bone inspection, global poultry AI databas...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Why do IP65/IP67 fail in food plants? Discover the...

MoreWhen a single shard of glass, a fragment of bone, ...

MoreCupped products, such as Greek yogurt and multi-co...

MoreOur AI X-ray Inspection System, tailored for high ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Quality Assurance ManagerThis X-ray inspection system has revolutionized our foreign object detection process. The sensitivity and accuracy in detecting metal, glass, and plastic contaminants in our packaged foods is exceptional. Reduced our false rejection rate by 70%.

Sarah Chen

Production SupervisorHighly reliable X-ray machine that integrates seamlessly with our production line. The automatic rejection system works flawlessly, and the user interface is intuitive. Minor learning curve for operators, but overall excellent performance in detecting contaminants in our bakery products.

David Thompson

Food Safety DirectorOutstanding X-ray inspection equipment that has significantly enhanced our food safety protocols. The system consistently identifies bone fragments in our meat products that were previously undetectable. The data logging feature provides perfect traceability for audits.

Jennifer Williams

Plant ManagerThis X-ray inspection system has been a game-changer for our canned food operations. It effectively detects metal contaminants in sealed cans without compromising production speed. The maintenance requirements are minimal, and technical support has been responsive when needed.