Comprehensive Introduction to IP69K Protection Rating — The Gold Standard for Equipment in Meat and Food Processing Environments

Why do IP65/IP67 fail in food plants? Discover the...

More

The x ray inspection machine price presents a clear choice for buyers. New equipment offers the latest technology and full warranties for maximum security. Used machines provide a significant initial saving of 50-70% for budget-conscious operations.

New Machines: $45,000 - $120,000

Used Machines: $20,000 - $60,000

The final x ray inspection machine price depends on many variables for both new and used models. Buyers must look beyond the sticker price to understand what drives the cost. A detailed analysis reveals the true value behind the investment.

The price of a new X-ray machine is not a single number. It is a total sum based on its specific design and capabilities. Several key factors determine this price range.

Technology and Features: Advanced technology drives up the cost. Features like high-resolution imaging, dual-energy detection, and artificial intelligence (AI) software add significant value and expense. Basic systems are less expensive. However, they may miss smaller or less dense contaminants.

Throughput and Size: Machines built for high-speed production lines cost more. Systems that handle larger products also have a higher price. Operations with moderate speed and size needs can use more affordable models.

Build Quality and Materials: The machine's construction impacts its price. A system made of high-grade stainless steel with an IP69K rating can withstand harsh washdown environments. This is common in meat and fish processing. Facilities with less demanding conditions can use standard, less expensive models.

Regulatory Compliance: Some systems must meet strict government regulations. This is especially true for certain food and pharmaceutical products. These machines require extensive testing and validation. This certification process increases the overall x ray inspection machine price.

Customization and Integration: A machine must often fit into an existing production line. The ability to customize the system and integrate it smoothly with other equipment will increase the total investment.

Used machines offer major initial savings, but their prices also vary. The machine's age, condition, and level of refurbishment are the most important factors. A high-quality refurbishment process ensures the system performs like new. This process involves careful selection, disassembly, and replacement of worn components with original manufacturer parts. It also includes software updates to the latest possible version.

"Used instead of new equipment saves us costs of almost 30 percent. This enables us to offer our patients a comprehensive range of high technical performance and diagnostic capabilities." —Steffen Klengel, MD, Director, Medical Care Center (MCC) RadCom GmbH

The quality of refurbishment varies greatly among suppliers. A manufacturer-certified process provides much higher quality and assurance than a simple third-party resale. The table below compares a manufacturer's certified program to the practices of many other competitors.

| Criteria | Manufacturer Refurbished System | Other Competitors |

|---|---|---|

| Selection | Strict criteria (age, service history); Systems from upgrade or lease programs. | Often no age restriction; May use systems with poor maintenance history. |

| Refurbishing | Full disassembly, cleaning, and painting; Worn parts replaced with original parts; Software updated to latest version. | No standardized process; May use non-original parts; Often resold without full system tests. |

| Warranty | Standard 12-month warranty, identical to a new system. | Often not available or very limited. |

| Parts Availability | Guaranteed availability of original spare parts for at least 5 years. | No guarantee of original spare parts. |

| Service | Full range of flexible service options available worldwide. | Usually no service options offered; Customer handles problems alone. |

A buyer must compare the technology of new and used machines. New systems provide the latest innovations. Used systems offer reliable, standard performance for common applications. The choice depends on a facility's specific inspection needs.

New X-ray machines deliver superior detection through advanced hardware and software. They excel at finding low-density contaminants like plastic, rubber, and bone. Dual-energy technology, combined with AI-powered software, dramatically improves detection accuracy. This technology separates the food product from foreign bodies in the X-ray image. The result is fewer false rejects and greater food safety.

Modern software also offers powerful tools for efficiency and compliance. Key advancements include:

Deep learning-powered image analysis

Automated anomaly detection

AI-enhanced reporting and workflow analytics

Advanced 3-D image visualization

The table below shows how new dual-energy technology outperforms older single-energy systems for detecting contaminants in chicken.

| Contaminant Type | New Dual-Energy Detection | Older Single-Energy Detection |

|---|---|---|

| Wishbone | 100% probability | Undetectable |

| Rib bone | 95% probability | Undetectable |

| Rubber (5mm) | 100% probability | 6mm minimum |

Used X-ray machines provide proven and effective capabilities for standard inspection tasks. These systems reliably detect dense contaminants like metal, glass, and stone. Their technology is well-understood and sufficient for many production environments. While they lack the latest AI features, their performance meets baseline food safety requirements.

Some manufacturers offer upgrade paths for their older equipment. These software updates can improve detection, enhance data logging, and ensure compliance with current standards. This allows a business to extend the life of a used machine. However, these upgrades may require one-time or annual fees.

A smart purchase decision looks beyond the initial sticker price. Buyers must analyze the Total Cost of Ownership (TCO) over the machine's entire lifespan. TCO includes not just the purchase price but also all operational, maintenance, and potential repair costs. This analysis reveals the true financial impact of choosing a new versus a used system.

A new X-ray machine requires a larger initial investment. However, this higher upfront cost provides financial predictability and significantly lower long-term risk. The comprehensive initial x ray inspection machine price often bundles many future expenses into a clear, manageable package. This approach protects a business from sudden, costly surprises.

The TCO for a new machine includes several key components:

Initial Purchase Price: This is the direct cost for the hardware, software, installation, and shipping.

Annual Running Costs: These are predictable expenses for power, water, compressed air, and sanitation.

Service Costs: New machines come with a full warranty, covering preventive maintenance, software updates, and operator training for an initial period.

Replacement Costs: The warranty typically covers premature failure of major wear parts like the generator or detector.

Labor Hours: Modern, user-friendly systems reduce the time operators spend on product setup and changeovers, lowering labor costs.

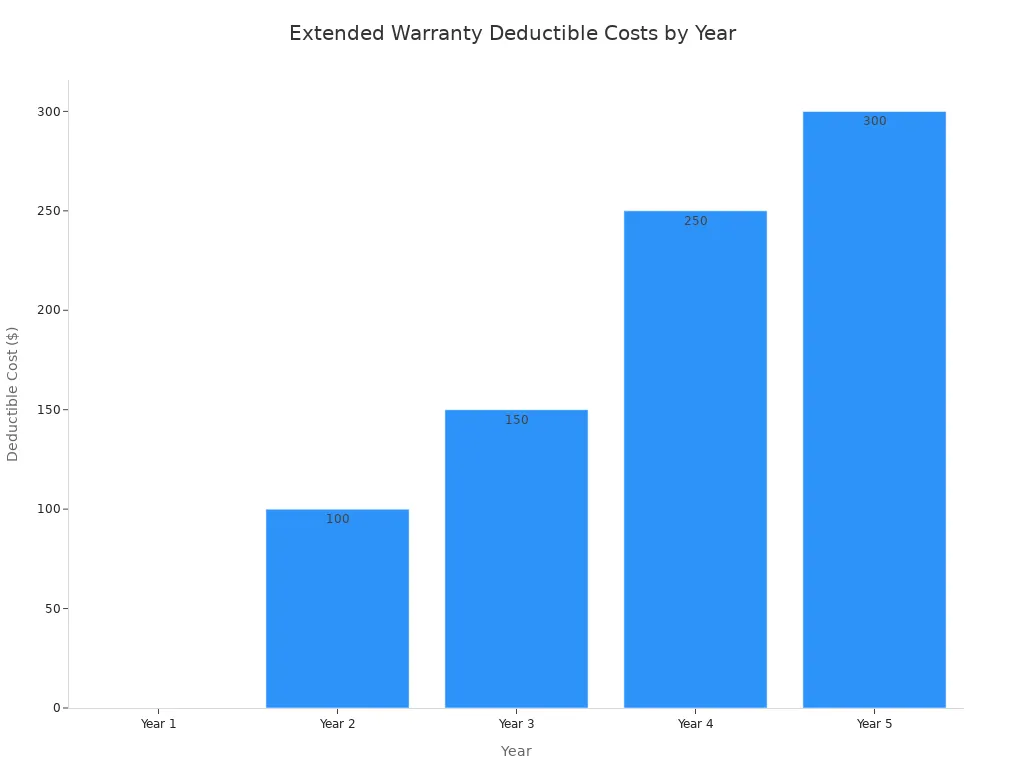

After the initial warranty expires, businesses can purchase annual service contracts for continued peace of mind. These contracts typically cost 8-15% of the original equipment price. They offer predictable maintenance budgets and protect against unexpected failures. Some extended warranty plans may introduce a small, escalating deductible over time.

This structure turns potentially catastrophic repair bills into manageable operational expenses.

A used X-ray machine offers a much lower entry cost, making it an attractive option for businesses with tight budgets. The initial savings can be substantial. However, this lower upfront x ray inspection machine price comes with higher potential risks and unpredictable future costs. These "hidden costs" can quickly erase the initial savings.

The biggest financial risk is not the repair bill itself. It is the loss of revenue from equipment downtime. Every hour the production line is stopped, the business loses money, which can far exceed the cost of a new machine.

Buyers of used equipment face several potential financial burdens. These often appear unexpectedly within the first few years of ownership.

Expensive Part Failures: Critical components like the X-ray tube, image intensifier, and camera are very expensive to replace. Many limited warranties for used equipment are prorated. This means the owner must pay a large portion of the replacement cost.

Cost of Downtime: A machine failure stops production. This directly results in lost revenue and can damage relationships with customers if orders are delayed.

Frequent Repairs: Older machines may require more frequent service calls and maintenance, adding to labor and parts costs.

Safety Compliance: A poorly functioning machine could lead to safety violations. The resulting fines and mandatory upgrades can be very costly.

While a used machine is cheaper to acquire, a business must budget for these potential high-risk expenses. Without a comprehensive warranty, the owner bears the full financial weight of any and all failures.

The long-term value of an X-ray machine depends heavily on its performance, expected lifespan, and the support structure behind it. New equipment provides clear advantages in warranty and parts availability, while used systems present significant variables.

Warranty and support create a major difference between new and used systems. New machines come with comprehensive manufacturer warranties that offer security and peace of mind. These warranties typically cover defects for a set period, protecting the initial investment. Used machines, in contrast, often have very limited or no warranty coverage, leaving the buyer responsible for all repair costs.

| Manufacturer | Warranty Duration | Common Coverage Details |

|---|---|---|

| PXSinc | 12 months | Defects in material and workmanship. |

| J. MORITA | 2-3 years | Defects in materials and workmanship. |

| Matsusada | 1 year | Excludes consumables like the X-ray tube after 1,000 hours. |

Furthermore, manufacturers provide rapid technical support for new systems. Urgent issues often receive a response within 24-48 hours. Many technical problems find resolution remotely in under 30 minutes, minimizing costly downtime. ⏱️

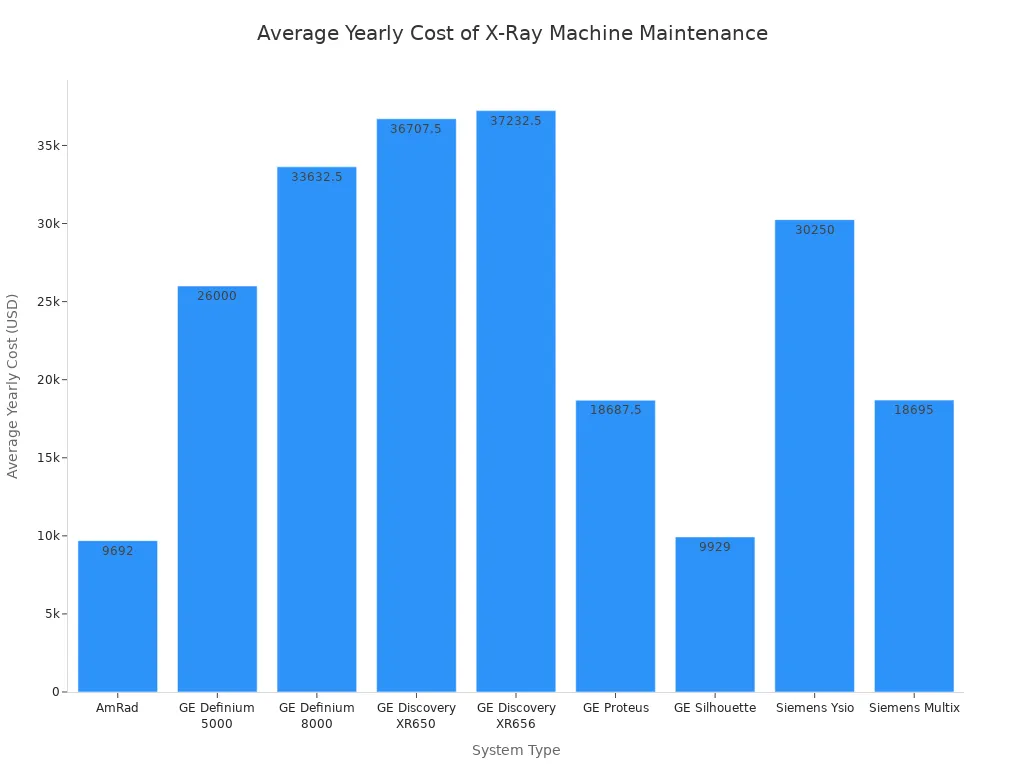

Proper maintenance is critical for any X-ray machine. A key component, the X-ray tube, typically operates for 3 to 7 years. Good maintenance can extend this lifespan for both new and used equipment. Owners of new machines can purchase full-service contracts for predictable annual costs, though these can be substantial.

Parts availability is another crucial factor. Finding spare parts for machines over 10 years old becomes very difficult. Manufacturers may discontinue parts for older models, making repairs impossible. This risk is almost non-existent with new machines, which have guaranteed parts availability for many years.

A business must weigh its specific needs against its budget to select the right equipment. New machines offer peak performance for demanding applications. Used machines provide a cost-effective solution for standard inspection tasks. The final decision impacts both safety compliance and long-term profitability.

A new X-ray machine is the best choice for businesses that require the highest level of performance and reliability. Industries with complex inspection needs see the greatest benefit from modern technology. These sectors often justify the higher initial x ray inspection machine price with a strong return on investment. For example, studies show AI platforms in radiology can yield a 451% ROI over five years.

Key applications that benefit from new technology include:

PCB & Battery Inspection: Detects tiny defects like solder voids and misaligned electrodes in electronics.

Food Inspection: Finds low-density contaminants like bone or plastic to ensure food safety.

Non-Destructive Testing (NDT): Examines internal flaws in aerospace and automotive parts without causing damage.

Security Screening: Uses AI-enabled scanners to find hidden contraband, as demonstrated by the Maricopa County Sheriff’s Office.

A used machine is a practical option for companies with standard inspection needs and limited capital. It allows businesses to implement essential quality control without a large upfront investment. However, buyers must perform thorough due diligence to avoid costly future problems. A careful inspection is critical to making a smart purchase.

Buyer's Checklist for Used Equipment:Before purchasing, a business should verify several key items. First, confirm the machine's operational status and review its complete service history. Next, understand its past usage patterns, such as hours of operation and the environment it came from. Finally, check for any hardware or software upgrades that may extend its useful life.

New machines represent a long-term investment in reliability and warranty-backed security. Used machines offer a budget-friendly entry point but carry risks of unforeseen costs that can outweigh initial savings. A buyer's final decision must balance the immediate budget advantage of used equipment against the long-term value of a new machine.

An X-ray tube, a key component, lasts 3 to 7 years. Good maintenance extends the machine's overall lifespan. This applies to both new and used equipment. ⚙️

Yes, some manufacturers provide software upgrades for older models. These updates can improve performance and compliance. The upgrades may require one-time or annual fees.

An annual service contract usually costs 8-15% of the original equipment price. This provides a predictable maintenance budget and protects against unexpected repair bills.

We provide you with comprehensive foreign trade solutions to help enterprises achieve global development

Ultra-fine contaminants detection, UHD X-Ray detec...

Recommedation: Rice, wheat, corn, grain, pulses, s...

Glass-in-glass / Metal-in-metal inspection, small ...

Recommedation: Aquatic products, pet food, candy, ...

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Why do IP65/IP67 fail in food plants? Discover the...

MoreX-ray inspection machines have become indispensabl...

MoreAdvanced nut sorting machine technology combines H...

MoreWhen a single shard of glass, a fragment of bone, ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: 717-490-1513

Add: 1050 Kreider Drive -

Suite 500, Middletown,

PA 17057

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Quality Control ManagerThe X-ray inspection machine was worth every penny! It has significantly improved our defect detection rate in electronic components. The price was competitive for the advanced features it offers.

Sarah Johnson

Food Safety InspectorGreat value for money! This X-ray machine has revolutionized our contamination detection in packaged foods. While not the cheapest option, the investment has already paid for itself in prevented recalls.

David Rodriguez

Production SupervisorAfter comparing multiple X-ray inspection machine prices, this one offered the best balance of cost and performance. The clarity and detection capabilities exceeded our expectations for the price point.

Emily Watson

Pharmaceutical ResearcherConsidering the advanced features, the X-ray inspection machine price was quite reasonable. It has been instrumental in maintaining our product quality standards without breaking our budget.